Aluminum extrusion is one of the most widely used processes for producing strong, lightweight, and cost-efficient profiles. Aluminum extrusion is essential for producing strong, lightweight, and cost-efficient components. This guide will explain the process, key components, advantages, and the growing popularity of aluminum extrusion among manufacturers.

What Is Aluminum Extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy by pushing it through a die with a specific cross-section. The process is analogous to squeezing toothpaste from a tube; when pressure is applied, the material emerges in the shape of the aperture.

Pushing a heated aluminum billet through a shaped steel die under high pressure produces a continuous profile that matches the die’s cross-sectional shape.

This process exploits aluminum’s unique physical properties. When heated, aluminum becomes malleable. After cooling, it retains its structural integrity. The end product has predictable dimensions and a high strength-to-weight ratio. It can also be shaped into virtually any form.

Main Components Used in the Aluminum Extrusion Process

Principal materials used in the extrusion of aluminum are:

Aluminum Billet

The starting material in the extrusion process is an aluminum billet. It is a solid block of aluminum alloy and has a cylindrical shape. Billets are normally cylindrical and cut to size from longer logs. Their lengths can vary depending on the required size and the press size.

The alloy used depends on the application needs, with the most commonly used alloys being 6000 series alloys in extrusion. Typically, alloy 6063is used in moderate stress applications. While the 6061 is chosen for structural applications requiring enhanced mechanical properties.

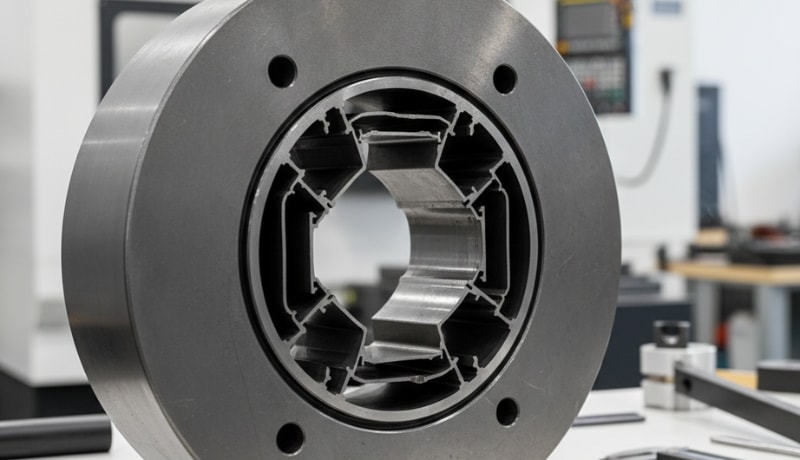

Extrusion Die

Circular steel disk with specific holes that define the final desired shape. It is made from heat-treated H-13 tool steel. The aluminum extrusion die is built to withstand extreme mechanical loads and increased temperatures linked to the aluminum extrusion process.

The opening of the die determines all the features of the extruded profile’s cross-section. These range from simple angles to complex multi-void designs.

Extrusion Press

The extrusion press is a hydraulic machine that provides the force needed to push the heated billet through the die. The size and capacity of such presses can range from 100 tons to 15,000 tons of pressure.

The size of the press determines the maximum circumscribed circle, defined as the smallest circle that completely encloses the extrusion’s cross-section. Innovative presses can produce architectural-quality extrusions with circumscribing circles exceeding 16 inches.

What Kinds of Shapes Can be Extruded?

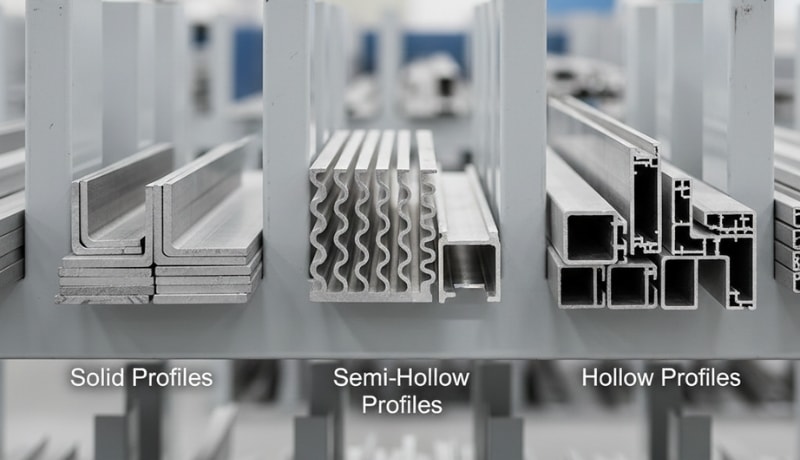

Aluminum extrusion offers excellent design flexibility. Manufacturers can create three main types of aluminum profiles: solid, semi-hollow, and hollow. The shapes of solids are not enclosed, and they envelop common extruded shapes such as angles, channels, beams and flat bars. These are the most cost-efficient to make and manufacture.

The hollow forms are completely hollow and feature one or more holes cut into their cross-section. Examples include tubes with circular, square, or complex internal profiles. These shapes require more complex dies that use mandrels. They are typically used for structural purposes where minimizing weight is essential.

The semi-hollow shapes partially contain a void, forming the profiles with a gap or an opening. These are intermediate between solid and hollow profiles. In fact, the difference between solid and semi-hollow is usually reduced to the tongue ratio. This is the mathematical expression of the area of the void and the gap size.

The semi-hollow dies are to be designed with caution to avoid breakage of the tongue in the high-pressure extrusion.

Direct and Indirect Aluminum Extrusion Process

Both extrusion processes are as follows:

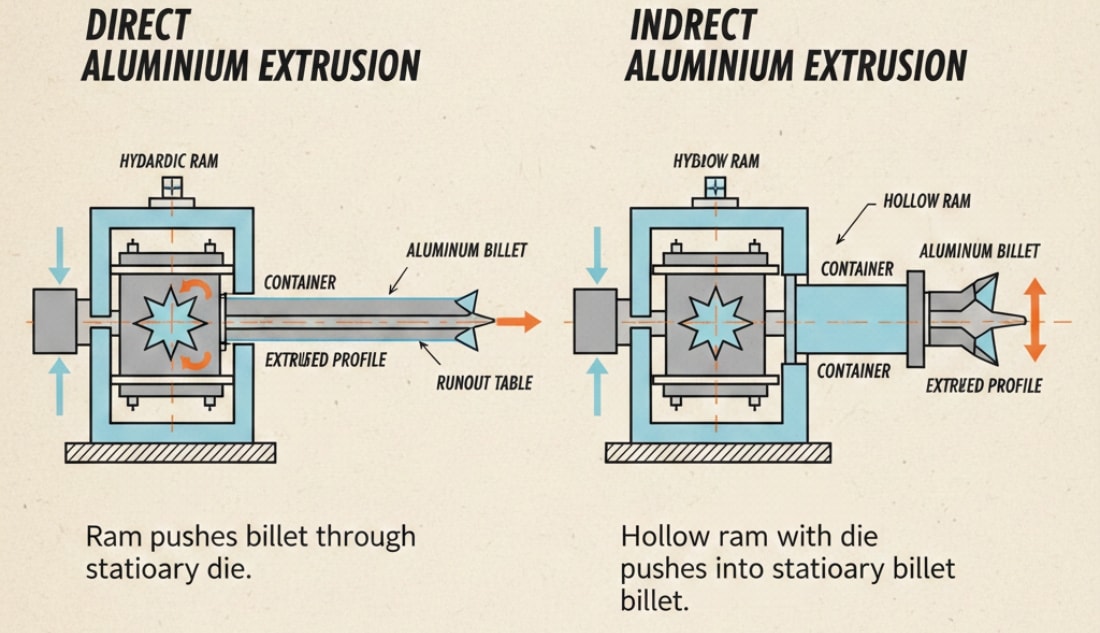

Direct Aluminum Extrusion Process

The most prevalent in the industry is the direct extrusion, also referred to as forward extrusion. Here, a billet of aluminum is pushed by a hydraulic ram with a dummy block on it, which is still in place. The ram is then driven through the die, pushing the billet through the container and forcing it through the die opening.

The flow of the billet and ram are in the same direction, and the flow of the aluminum is through the die. The process creates significant friction between the billet and the container walls. This results in heat generation and the need for increased pressure.

Indirect Extrusion Process

Backward extrusion, also known as indirect extrusion, works differently. The billet is fixed, and the die is pushed upon a hollow ram passing over it. The aluminum is squeezed back through the die, and it is released at the other end. Since the billet will not move with respect to the container walls, less friction is produced using this technique.

Several benefits are gained through the decreased friction in the indirect extrusion process. This includes an enhanced ability to control heat. It also offers more consistent product quality and a greater force available throughout the process.

The Aluminum Extrusion Process in 12 Steps

Step 1 – Prepare Extrusion Die

The step involves the preparation of the extrusion die; This can be either machined out of H-13 steel or chosen off-the-shelf. The die’s preheat temperature is set between 750°F and 900°F. This makes the flow of aluminum more stable. It also reduces thermal shock, which helps the die last longer.

Step 2 – Preheat the aluminum billet

A heated aluminum billet is cut to size and then heated in an oven up to 750–900°F, according to the alloy. This temperature softens the aluminum. It becomes easier to shape. It does not reach the melting point. This ensures proper mechanical properties.

Step 3 – Billet loading into the Extrusion Press

To ensure that the billet and ram do not stick together, a lubricant or release agent is applied to them. The billet is then moved to the extrusion press and fitted into the press cradle.

Step 4 – Force Billet Material into the Extrusion Press Container

The ram, which has a dummy block attached to it, presses the billet. The container is sealed with the dummy block that does not allow backflow. The billet also deforms under pressure and flows to the die.

Step 5 – Extrude the billet through the die

Under the pressure, the softened aluminum is pushed through the opening of the die. The die cross-sectional shape is assumed by the metal; the pressure would be under control so as to ensure regular flow and eliminate flaws.

Step 6 – Quench the Extrusions

With the rapid exit of the profile, air fans or water quenching are used to cool the profile. Proper quenching locks in the desired mechanical properties and helps control distortion in heat-treatable alloys.

Step 7 – Shear Extrusions to Table Length

When the extrusion is long enough to be table length, a hot saw cuts the extrusion out of the continuous profile. The rest of the butt section, which has surface oxides on it, is discarded and recycled.

Step 8 – Cool Extrusions to Room Temperature

The extrusions are passed to cooling tables where they are allowed to cool gradually to ambient temperature.Controlled cooling helps minimize residual stress and maintain consistent properties.

Step 9 – Extrusions Transported to the Stretcher and stretched into Alignment

The cold profiles are elongated to eliminate twists and bends. This reduces twists and residual stresses, ensuring dimensional consistency. Straight extrusions are cut to customer specifications, typically with tight tolerances. They are easy to handle and can be split for use or processing.

Step 10 – Extrusions are cut to length using the finish saw

In order to prepare straightened extrusions for ultimate use or processing, they are precisely cut to customer-specified lengths, usually within strict tolerances.

Step 11 – Heat Treatment / Aging

Extrusions undergo either natural or artificial aging depending on the alloy. The heat treatment enhances the aluminum by strengthening it through precipitation hardening, improving mechanical performance.

Step 12 – Finishing and Secondary Operations

Last operations can include anodizing and powder coating. Alternatively, they may involve CNC machining, drilling, bending, or welding, depending on the application requirements.

Benefits of Aluminum Extrusion

Here are the benefits of the aluminum extrusion process:

Design Flexibility

Extruded material offers a highly customized appearance. They can combine strength, hollowness, and assembly features into a single part. This reduces the number of parts needed and shortens production time.

Strength-to-Weight Ratio

Aluminum material extrusions are very lightweight yet durable. They are commonly used in transportation, aerospace, and structural applications where reducing weight improves efficiency and performance.

Cost Efficiency

Aluminum extrusion is cost-effective, reducing tooling costs, waste, and machining. Its recyclable scrap also lowers shipping charges.

Corrosion Resistance

Aluminum naturally forms a protective oxide skin, which provides excellent protection against rust. This layer also guards against environmental degradation. Durability is increased by the use of anodizing and coatings.

Sustainability and Recyclability

Aluminum can be recycled indefinitely and with minimal energy consumption costs. Compared to most metal processes, extrusion is not energy-intensive and, therefore, is environmentally friendly.

Conclusion

Aluminum extrusion is a high-performance production technique. It allows for creating sophisticated shapes. The process results in lightweight structures that are durable. Its ability to produce stable profiles with high strength-to-weight ratios makes it essential in construction, automotive, electronics, and industrial manufacturing.

Sustainability and efficiency are now key in modern manufacturing. Aluminum extrusion remains a dependable solution. It can produce unique products and manage large-scale production just as effectively in the future.

Let Honjenny Assist You in Aluminum Extrusion – Free Quote today!

Choosing the right manufacturing partner is vital for construction, transport, electronics, and precision products.

Honjenny provides premium metal services, including aluminum die casting, rapid prototyping, CNC machining, and surface finishing. These services are supported by decades of engineering expertise and rigorous quality control.

To request a quote, contact us and present your extrusion design. Seek technical consulting on material selection or manufacturing.