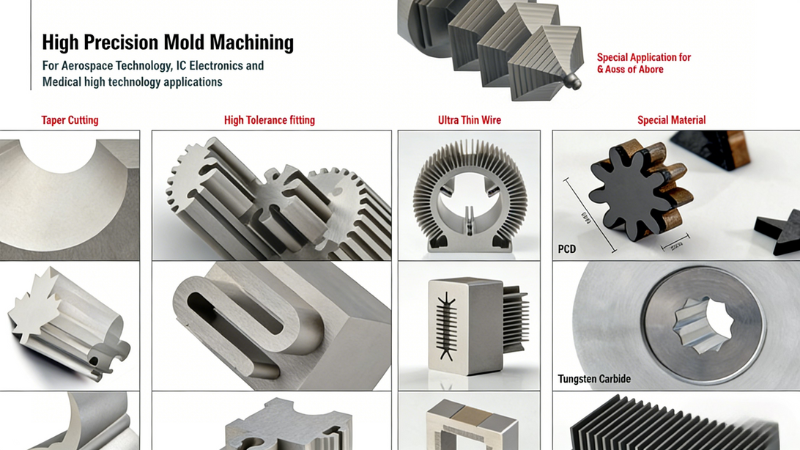

It’s not always possible to shape and size every kind of geometry through standard CNC machining ways. Some items demand ultra-tight tolerances, intricate geometries, or cutting from hardened materials.

That’s when designers/engineers/manufacturers look into Electrical Discharge Machining (EDM). It can create complex shapes, fine details, and smooth finishes that would be impossible with standard CNC.

EDM production is gaining traction in sectors involving absolute precision and advanced technology. Explore the EDM machine, its inner mechanism, different EDM types, and its comparative benefits.

What Is an EDM Machine?

An EDM machine is a high-precision, non-contact machining tool. It uses controlled electrical discharges (sparks) to erode material. The mechanism works well on complex shapes, hard metals, and ultra-tight tolerances.

Alternatively, Electrical Discharge Machining (EDM) is a manufacturing process. It removes the material from a workpiece using a series of rapid electrical discharges between two electrodes, separated by a dielectric fluid.

EDM doesn’t require physical contact between the tool and workpiece. Instead, sparks vaporize and melt material at microscopic levels. EDM is effective for hard, electrically conductive materials like titanium alloys, carbides, etc.

Key Components and Tools in Electrical Discharge Machining

a. Power Supply with Pulse Generator

Controlled electrical pulses generate sparks between the electrode and the workpiece. Modern EDM uses high-frequency pulse generators to produce hundreds of thousands of sparks per second.

b. Electrodes (Tool Electrode and Wire)

- Wire EDM: Brass, copper, or coated wires as thin as 0.02 mm for intricate cuts.

- Sinker EDM: Shaped electrodes (graphite, copper, tungsten) to form cavities.

- Hole-Drilling EDM: Tubular electrodes for micro-holes.

Electrode quality directly affects machining accuracy. High-grade copper electrodes reduce wear and improve tolerances.

c. Dielectric Fluid System

It acts as an insulator until breakdown voltage is reached, then cools sparks and flushes debris. Poor flushing can cause unstable sparks and reduced accuracy. Types include –

- Deionized water (wire EDM) for efficient cooling and flushing.

- Hydrocarbon oils (sinker EDM) for smoother finishes.

d. Servo Control System

It maintains the optimal spark gap (10–100 microns) between the electrode and workpiece. Prevents short circuits, ensures consistent discharges, and improves machining stability.

e. Workpiece Holding Fixtures

It securely holds the workpiece to prevent vibration or misalignment. Essential for achieving tolerances as fine as ±0.005 mm.

f. Monitoring with IoT Systems

Sensors track spark gap, dielectric quality, and electrode wear in real time. Enables predictive maintenance, reduces downtime, and ensures consistent quality.

g. Auxiliary Tools + Consumables

- Wire Guides and Tensioners: Maintain wire alignment in wire EDM.

- Filtration Systems: Remove debris from dielectric fluid to prevent contamination.

- Cooling Units: Stabilize machine temperature, critical for micron-level accuracy.

How Electrical Discharge Machining Works: EDM Mechanism

a. Spark Generation

- Electrical Pulses with Gap Voltage

EDM relies on a controlled electrical discharge between the tool electrode and the workpiece. A voltage is applied across a small gap (typically 10–100 microns) filled with dielectric fluid. When the gap voltage exceeds the breakdown strength of the dielectric, a spark is generated.

- Spark Energy and Removal Rate

Each spark carries energy proportional to the pulse current and duration. Higher energy sparks remove more material but reduce surface finish quality. Lower energy sparks produce finer finishes but slower removal rates.

Industrial EDM devices can generate hundreds of thousands of sparks per second, enabling efficient machining of complex geometries.

b. Material Removal Mechanism

- Localized Melting for Vaporization

Each spark creates temperatures up to 12,000 °C, melting and vaporizing a tiny portion of the workpiece. The molten material is expelled into the dielectric fluid.

- Crater Formation and Cumulative Erosion

The spark leaves behind a microscopic crater. Successive spark eroding forms overlapping craters, gradually shaping the desired geometry. Such a cumulative erosion allows EDM to cut hardened steels, carbides, and superalloys that conventional CNC tools struggle with.

Role of Dielectric Fluid

- Cooling Sparks: Absorbs heat from the discharge zone, preventing thermal damage to both electrode and workpiece.

- Maintaining Spark Gap: Ensures consistent electrical breakdown by stabilizing the gap voltage.

- Flushing Molten Debris (Swarf): Removes eroded particles, preventing short circuits and maintaining machining efficiency.

- No Unintended Arcing: By insulating the electrodes until the breakdown voltage, the dielectric fluid avoids uncontrolled discharges that could damage the surface.

Different Types of EDM Machines

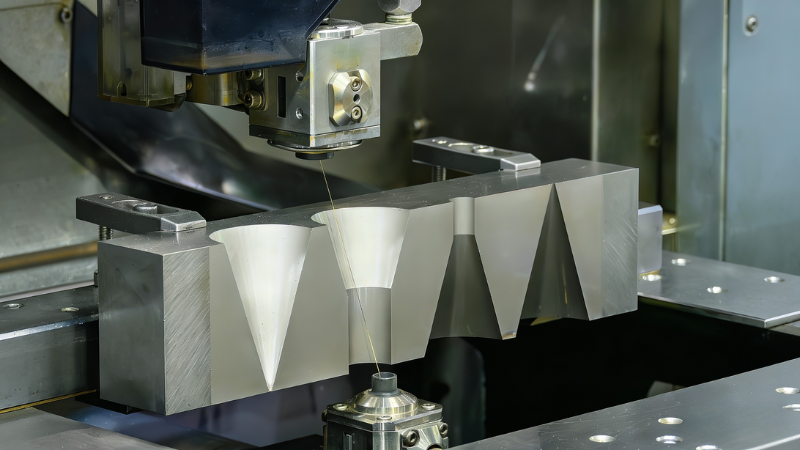

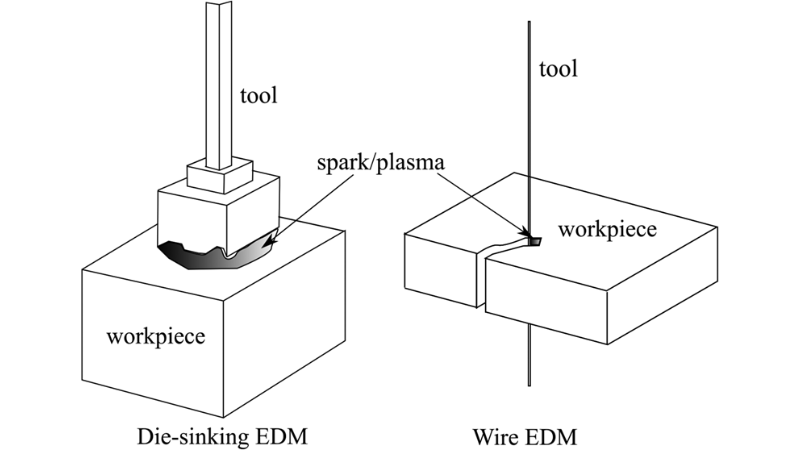

01. Wire EDM Machines (Wire-Cut EDM)

The electric discharge machining uses a continuously fed thin wire electrode (brass, copper, or coated wire) to cut through conductive materials. The sparks erode material along the programmed path. It operates in a dielectric fluid (deionized water) that cools and flushes debris.

Top Advantages

- Extreme Precision: Wire electrical discharge machining can achieve tolerances of ±2–3 microns.

- Complex Shapes: Cut intricate contours, sharp internal corners, and delicate geometries.

- No Mechanical Stress: No contact means no distortion of fragile parts (workpiece material).

- Automation-Friendly: CNC-controlled wire EDM allows unattended machining of complex parts.

Notable Limitations

- Only works on electrically conductive materials.

- Slower cutting speed compared to conventional CNC milling for bulk removal.

- Wire consumption adds to the EDM operation costs.

Common Applications

- Aerospace: Cutting turbine components with micro cooling channels.

- Medical: Producing surgical instruments and implants with fine details.

- Electronics: Manufacturing micro-components for semiconductors.

- Toolmaking: Precision dies for injection molding and stamping.

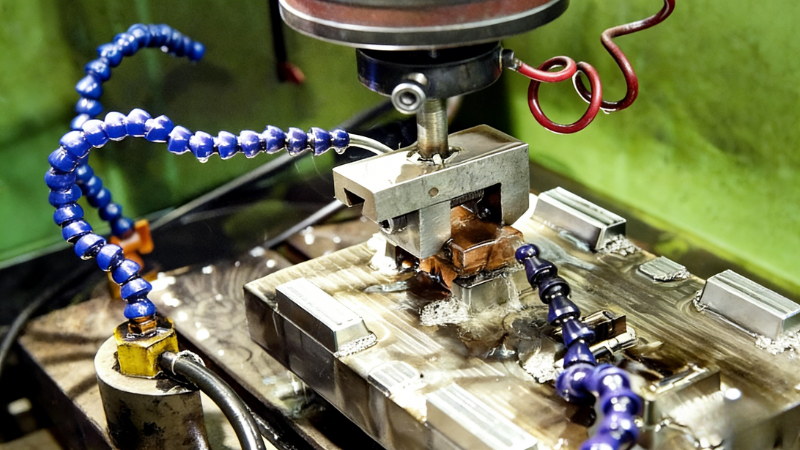

02. Sinker EDM (Ram / Die-Sinking EDM)

It uses a shaped electrode (graphite, copper, or tungsten) that “sinks” into the workpiece to form cavities. The electrode is custom-made to mirror the desired shape. A sinker EDM operates in hydrocarbon oil dielectric fluid, which provides smoother finishes.

Top Advantages

- Versatility: Can produce deep cavities and complex 3D shapes.

- Surface Finish: Achieves mirror-like finishes (Ra 0.1 µm) suitable for molds.

- Hard Material Machining: Easily erodes hardened steels and carbides.

- Customization: Electrodes can be tailored for unique mold designs.

Notable Limitations

- Electrode Wear: Electrodes degrade over time, requiring replacement.

- Higher Setup Costs: Custom electrodes increase preparation time and expense.

- Slower than Wire EDM: It applies to cutting through-thickness parts.

Common Applications

- Mold Making: Injection molds for plastics, die-casting molds for metals.

- Automotive: Engine components requiring deep cavities.

- Consumer Electronics: Precision molds for smartphone casings and connectors.

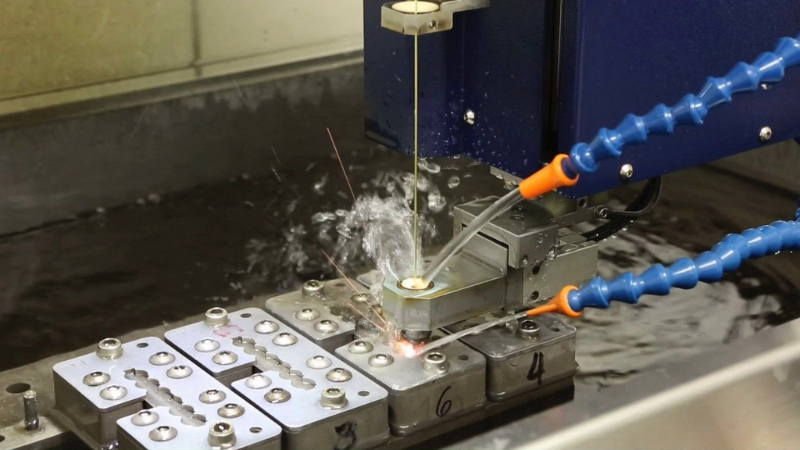

03. Hole-Drilling EDM (Fast Hole EDM)

It uses a rotating tubular electrode to drill small, deep holes quickly. Dielectric fluid flows through the electrode, flushing debris while sparks erode material. The EDM is capable of drilling holes as small as 0.1 mm in diameter.

Top Advantages

- Machining Speed: Can drill hundreds of holes in minutes.

- Depth Capability: Produces holes with high aspect ratios (depth-to-diameter).

- Essential for Aerospace: Creates cooling holes in turbine blades.

- No Mechanical Force: Perfect for delicate components.

Notable Limitations

- Limited to conductive materials.

- Not suitable for large cavities, only specialized for holes.

- Surface finish is rougher compared to wire or sinker EDM.

Common Applications

- Aerospace: Drill thousands of cooling holes in turbine blades.

- Medical: Micro-holes in surgical instruments and implants.

- Electronics: Ventilation holes in micro-components.

Comparison of EDM Machine Types (Other Machining Processes)

Key Takeaway

- Electrical discharge machining process (Wire EDM) is the best for precision contour cutting.

- Ram EDM dominates in mold making and deep cavity machining (cavity-type EDM).

- EDM hole-drilling suits fast, tiny, deep holes with specialized electrode materials in aerospace.

Materials Suitable for EDM Manufacturing

EDM exclusively on electrically conductive materials. Without conductivity, no discharge can occur. It turns EDM unsuitable for plastics, cer amics, or non-conductive composites. Some materials –

- Tool Steels (H13, S7, P20)

Tool steels are hardened and wear-resistant, making them difficult for CNC cutting tools. EDM erodes them effortlessly. Applications include –

- H13: Hot-work tool steel, widely used in die-casting molds.

- S7: Shock-resistant steel, ideal for stamping dies.

- P20: Pre-hardened mold steel, common in plastic injection molds.

- Stainless Steel

Resistant to corrosion and tough to machine conventionally. EDM bypasses mechanical cutting challenges. Applications include surgical instruments, aerospace fasteners, and precision molds.

- Carbide

Carbide is extremely hard (>70 HRC), making it nearly impossible to machine conductive materials with traditional tools. Applications include cutting tools, wear-resistant dies, and precision punches.

- Titanium Alloys

Ti’s high strength-to-weight ratio and heat resistance make it vital in the aerospace and medical device industries. Applications include aerospace turbine components, orthopedic implants, and dental tools.

- Inconel

A nickel-based superalloy, Inconel, withstands extreme heat and corrosion but is notoriously difficult to cut with CNC. Applications include jet engine turbine blades, nuclear reactor components.

- Copper Alloys

Copper alloys are conductive and used both as workpieces and electrodes. Applications include electrical connectors, precision molds, and EDM electrodes themselves.

How EDM Machines Improve Precision Manufacturing?

- CNC-Controlled Electrodes

Modern EDM machines integrate CNC systems to control electrode movement with micron-level accuracy. It ensures repeatability in complex cavity machining. Reduced human error speeds up the production cycles.

- High-Speed Wire EDM Process

Wire EDM uses a continuously fed wire electrode to cut intricate contours. High-speed models can generate hundreds of thousands of sparks per second.

It cuts complex geometries faster without sacrificing accuracy. Production of micro-components in consumer electronics and medical instruments becomes simple.

- Automation and Robotic Loading

EDM machines increasingly integrate robotic arms for electrode/tool loading and part handling. It enables lights-out manufacturing (unattended operation).

You can expect improved output for reduced labor costs. Automated EDM systems can increase productivity by 20% – 40% compared to manual setups.

- High-Quality Surface Finishes Using Fine-Finish Settings

EDM machines allow operators to adjust spark energy and pulse duration for fine finishing. It produces mirror-like finishes (Ra 0.1 µm), eliminating or reducing polishing.

Such finishing is critical for molds, implants, and precision dies. Fine-finish EDM reduces post-processing time by up to 50%, saving costs in mold-making industries.

- IoT-Enabled EDM Monitoring Systems

Modern EDM machines are equipped with IoT sensors that monitor spark gap, dielectric fluid quality, and electrode wear in real time.

Predictive maintenance reduces downtime. Data analytics optimize machining parameters for efficiency. IoT-enabled EDM systems can reduce unplanned downtime by up to 25%.

- Tool Life Optimization

EDM minimizes excessive tool wear since there is no physical contact between the tool and workpiece. The electrodes last longer, reducing replacement costs.

Predictable wear patterns allow better planning of electrode usage. Optimized management can cut tooling costs by 15–20% in high-volume EDM production.

Role of EDM in the Die Casting Supply Chain

- EDM as the Backbone of Die Casting Tooling

Die casting molds + dies from hard tool steels must withstand extreme pressures and temperatures. Conventional CNC struggles with complex cavities, sharp corners, and intricate cooling channels. EDM can erode hardened materials with sparks rather than cutting tools.

- Precision Mold Cavities for High-Quality Castings

EDM lets manufacturers create deep cavities and fine details in die casting molds. Such precision makes the cast parts meet dimensional accuracy and surface finish requirements.

- Cooling Channels and Thermal Management

Die casting molds require complex cooling channels to regulate temperature during casting cycles. EDM drilling, creating micro cooling holes and channels, improves cooling efficiency and extends mold life.

- Extending Tool Life and Reliability

EDM produces molds with smooth finishes (Ra 0.1 µm), reducing friction and wear during casting. It extends the tool life, lowers maintenance costs, and ensures reliable production runs.

- Complex Geometries in Modern Die Casting

Industries increasingly demand intricate designs, making EDM a more common solution. Multi-axis EDM allows tapered cuts and 3D profiles, producing complex castings that meet global standards.

EDM vs CNC Milling: When to Use Which?

Core Difference

EDM removes material through controlled electrical sparks. The non-contact process erodes conductive materials. It’s ideal for hardened steels, superalloys, and complex geometries.

CNC milling uses rotating cutting tools to mechanically remove material. It’s faster for bulk removal that works on many materials. You can cut non-conductive materials like plastics and composites.

When to Choose EDM?

- Hardened Materials: Machining tool steels, carbides, titanium, and Inconel, materials that cause tool wear in CNC.

- Complex Geometries: Produces sharp internal corners, deep cavities, and micro-holes that CNC tools cannot reach.

- Ultra-Tight Tolerances: EDM achieves tolerances of ±0.002–0.005 mm and surface finishes as fine as Ra 0.1 µm.

When to Choose CNC Milling?

- Bulk Material Removal: CNC is significantly faster, with removal rates exceeding 100 mm³/min.

- Non-Conductive Materials: Works on plastics, composites, and ceramics, which EDM cannot machine.

- Cost Efficiency: Lower operating costs for large parts and high-volume production.

- Versatility: Can perform drilling, contouring, pocketing, and surface finishing in one setup.

Hybrid Approach: CNC + EDM

Many industries combine CNC and EDM to balance speed and precision. CNC handles roughness, whereas EDM delivers the finishing.

At a Glance: EDM vs CNC

Emerging EDM Technologies

- Micro-EDM (Opposite to Conventional Machining)

It uses ultra-fine wire diameters as small as 0.02 mm and can machine feature sizes down to 10 μm. Enables fabrication of micro-components with extreme precision, beyond the reach of conventional machining methods.

Common Applications

- Micro-molds for electronics and medical devices.

- Medical devices such as stents, pacemakers, and micro-surgical tools.

- Micro-connectors, semiconductor dies, and MEMS (Micro-Electro-Mechanical Systems).

- Fast Hole Drilling (EDM Hole)

It uses high-frequency power supplies to generate rapid discharges. It makes the workpiece electrode work 3–5 times faster than conventional EDM (small-hole EDM). Dramatically reduces cycle time for drilling hundreds of holes in aerospace components.

Common Applications

- Turbine blade cooling holes for thermal regulation.

- Fuel injector nozzles in automotive parts and aerospace engines.

- Multi-Axis EDM Tool

5-axis Wire EDM allows tapered cuts, angled geometries, and complex 3D profiles. Robotic EDM integrates robotic arms to control axis movements for large components and complex setups. Expanded EDM capability from 2D contour cutting to full 3D machining rivals other machining methods.

Common Applications

- Aerospace: Complex turbine discs, compressor blades, and structural components.

- Large tooling: Precision molds for automotive and consumer electronics.

- Additive + EDM Hybrid Machining Methods

It combines metal 3D printing with EDM by directly printing electrodes, eliminating traditional electrode fabrication. Reduces electrode production time and cost. Enables rapid tooling for molds and dies.

Common Applications

- Rapid tooling in automotive and consumer electronics.

- Custom electrodes for complex mold cavities.

FAQs

-

Can an EDM machine non-conductive materials?

No. EDM requires electrical conductivity. Non-conductive materials like plastics or ceramics cannot be machined unless specially treated.

-

How accurate is EDM machining?

EDM can achieve tolerances of ±0.002–0.005 mm. Also, the fine surface finishes (as fine as Ra 0.1 µm) suit medical and aerospace parts.

-

What is the role of dielectric fluid in EDM?

Dielectric fluid cools sparks, maintains the gap, flushes debris, and prevents arcing, ensuring stable machining.

-

How long does EDM machining take?

EDM is slower than CNC. Removal rates are typically 2–10 mm³/min, but precision and complexity justify the time investment.

-

Is EDM environmentally friendly?

Traditional EDM uses hydrocarbon oils, which pose disposal challenges. Modern EDM systems use eco-friendly dielectric fluids to meet global sustainability standards.

Conclusion

Electrical Discharge Machining (EDM) lets you enjoy precision, innovation, and possibility. Conventional CNC machining reaches its limits, and EDM simply gets started. It delivers accuracy in microns, flawless finishes, and the ability to shape hardened materials into complex geometries.

Metal Die Casting at Its Finest with Absolute Precision at HONJENNY

Honjenny has been a top name across the global metal casting industry. We continue to satisfy clients worldwide for about 30 years. Contact us to understand further about our top-tier casting services.