6063 aluminum is one of the most widely used extrusion alloys worldwide, especially for architectural and decorative profiles. It is valued for excellent extrudability, smooth surface finish, and strong corrosion resistance.

In this guide, you’ll learn what 6063 aluminum is, how its chemistry affects performance, the differences between common tempers (T5 vs. T6), and where 6063 is typically used.

What Is 6063 Aluminum?

6063 belongs to the 6xxx series of aluminum alloys (Al–Mg–Si). It is a heat-treatable alloy designed for extrusion, meaning it can be formed into complex cross-sections with consistent dimensions and a high-quality surface.

Magnesium and silicon combine toform magnesium silicide (Mg₂Si), which enables precipitation hardening after heat treatment. This gives 6063 a practical balance of formability, corrosion resistance, and moderate strength—making it a popular choice for window and door frames, curtain walls, railings, trims, and other visible extruded components.

Alloys in the 6000 series are generally easy to extrude and weld, are heat-treatable, and are widely used in architectural and structural applications depending on strength requirements.

Why 6063 Is Known as the “Architectural Aluminum Alloy”

6063 is often called the “architectural aluminum alloy” because it delivers an excellent surface finish, extrudes easily into complex shapes, and takes anodizing and powder coating very well.

- Exceptional extrudability of complex and thin-walled profiles.

- Shiny, straight surface finish.

- Excellent anodizing and powder coating.

These 6063 aluminum properties make it the best choice for visible parts like door frames, curtain walls, sign frames, railings, and decorative trims.

Chemical Composition of 6063 Aluminum

6063 aluminum is mostly made up of aluminum extrusion alloyed with magnesium and silicon, with tiny quantities of iron and other major alloying elements added to improve strength, extrusion, and corrosion resistance.

What These Elements Do

Magnesium plus Silicon (Mg + Si)

These two elements combine to generate magnesium silicide, which allows for precipitation hardening and increased strength following heat treatment.

Iron (Fe)

Iron, an impurity, must be regulated to avoid diminished ductility and surface quality.

Minor elements (Cu, Cr, Zn, and Ti)

These trace elements help control grain structure, extrusion behavior, and overall processing stability while having no appreciable effect on corrosion resistance.

6063-T5 vs. 6063-T6: Understanding the Tempers

The alloy’s temper determines its performance. The most common tempers for 6063 are T5 and T6.

Mechanical Property Comparison

Note: Values below are typical ranges and can vary by product form, thickness, and applicable standards.

Key Differences Explained

6063-T5

Shaped at high temperature and cooled, followed by artificial aging. It has good strength and a good surface finish, and has extensive applications in architectural profiles.

6063-T6

It is an artificially aged and solution heat treated aluminum that offers greater hardness and strength , while maintaining good corrosion resistance suitable for most architectural environments. It is used when greater mechanical performance is needed and corrosion resistance is good.

Key Properties of 6063 Aluminum

6063 aluminum has become known for its combination of formability, appearance, and performance in common applications.

Extrudability and Dimensional Stability

6063 aluminum is suited for complex, thin-walled shapes. Its reliable extrusion technique provides precise dimensions and uniform forms.

Surface finish

One of its main features is its high surface quality. It functions flawlessly with:

- Anodizing

- Powder coating

- Spray painting

This makes it appropriate for both decorative and visible products.

Corrosion Resistance

6063 is a good material resistant to rust, particularly in the open air. It has a better long-term exposure than a number of other alloys.

Thermal Conductivity

Aluminum’s conductivity to heat is also highly useful, as it is used where heat has to be dissipated, such as in heat sinks and electronic covers.

Density

With a density of about 2.70 g/cm³, 6063 is lightweight and well-suited for light-to-moderate load applications typical of architectural profiles.

6063 vs 6061 Aluminum: What’s the Difference?

The most common extrusion alloys are aluminum 6063 and 6061, which are useful in different applications.

6061 Aluminum: The “Workhorse.”

It is the structural alloy of choice. It is very strong, corrosion-resistant, and weldable. It will be used in truck frames, bridges, and aerospace parts where its longevity is not negotiable.

6063 Aluminum: The “Architectural” Choice

6063 is also valued due to its high-quality finish. It is very extrudable, that is, it can be extruded into intricate forms with smooth surfaces that anodize very well. It is a little weaker than 6061, and it is perfect for window frames, railing, and decorative trims.

Common Applications of 6063 Aluminum

6063 aluminum is the most commonly used alloy applied in situations where corrosion resistance, appearance, and accuracy of extrusion performance should be considered. It is particularly the ideal material in multiple industries, with its great surface finish and capability to create complex, thin-walled profiles, to use in architectural, decorative, and heat-dissipation components.

Architectural profiles

Applied to facades, architectural framing, structural profiles, window frames, and door systems, 6063 aluminum is clean, dimensionally consistent, and displays extreme resistance to exposure to the outdoor environment.

Aluminum fences and railings

This corrosion resistance and finishes are made of the alloy, which is best suited for balconies, stair railings, as well as external fencing, where the durability of the alloy is necessary with the visual appeal.

Decorative trims and frames

Aluminum 6063 is also used widely in trims, frames, and architectural accents where a fine look and a regular finish are needed.

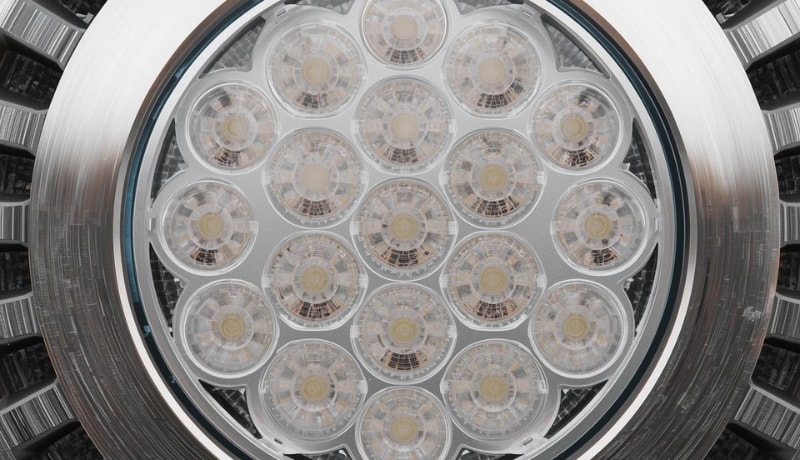

LED light housings

Aluminum LED housing simplifies forming precise enclosures that help dissipate heat and extend LED lifespans. It is good in thermal conductivity and also very extrudable.

Heat sinks

The flexibility of the alloy in making thin fins and complex shapes has made it useful in heat sinks in electronics, lighting, and power systems.

Furniture frames

6063 aluminum is lightweight and stable, frequently employed in furniture frames, offering structural integrity along with a contemporary, clean appearance.

Solar panel frames

6063 is widely used for solar panel frames thanks to its corrosion resistance, low weight, and long-term outdoor durability.

Why choose 6063 aluminum?

6063 aluminum is chosen when the project values surface quality, formability, and corrosion resistance more than maximum mechanical strength. It is particularly appreciated in situations when the visual impression and the production effectiveness are the main factors.

Excellent surface finish

Makes smooth, even surfaces which are perfect when it comes to anodizing, powder coating, and painting.

Complex extrusion shapes

Permits complex cross-sections and thin-walled, which is hard to obtain with other alloys.

Good corrosion resistance

It works well in outdoor and atmospheric conditions, so it can be used in architecture and as exterior furnishings.

Lightweight material

Its density of about 2.70 g/cm3 is advantageous to lower the overall weight of the system while maintaining durability.

Stable quality in high-volume manufacture

Controlled extrusion gives reliability to the dimensions and consistency of quality in mass production.

Generally, 6063 aluminum provides a great compromise in terms of both looks and functionality, and pricing, when it is not used as a structural alloy.

Advantages and Disadvantages of 6063 Aluminum

Knowing the strengths and weaknesses of 6063 aluminum allows engineers and designers to decide whether it is the correct material to use in this particular application or not.

Advantages

Outstanding extrudability

One of the simplest aluminum alloys to extrude, allowing intricate forms with close tolerances.

Great anodizing capacity

Produces bright, consistent anodized finishes, which are the best in visible parts.

Smooth surface appearance

Naturally provides clean faces, and therefore, minimal secondary finishing is required.

Good corrosion resistance

Safe to use in the long-term and in the open air and humid regions.

Lightweight and easy to handle

Ensures ease in machining, handling, and transportation, and assists in controlling the cost of manufacturing expenses.

Disadvantages

Lower strength compared to 6061

Not applicable to applications with high mechanical strength.

Unsuitable with heavy structural loads

Architectural, decorative, and light-duty purposes, more than load-bearing structural applications.

FAQs

Is 6063 aluminum strong?

It is a medium strength alloy known as an architectural alloy. It is sufficient for building purposes as well as decorative purposes, but less than that of 6061.

Is 6063 aluminum weldable?

Yes. 6063 is weldable using common processes such as TIG or MIG. Filler selection depends on the required strength, appearance, and corrosion performance.

What is the difference between 6063 – T5 and 6063 -T6?

6063-T6 undergoes solution heat treatment followed by artificial aging, resulting in higher strength than T5, which is aged directly after extrusion.

Is 6063 good for structural work?

6063 is used for light-to-moderate structural applications (especially architectural profiles), but for higher-load structural parts, 6061 (or other higher-strength alloys) is often preferred.

Is 6063 suitable for anodizing?

Without a doubt, 6063 is one of the finest to use in anodizing due to its smooth and flat surface.

Conclusion

6063 aluminum is a reliable extrusion alloy known for its smooth finish, excellent corrosion resistance, and strong coating performance. While it is not the highest-strength 6xxx alloy, it is an excellent choice for architectural and decorative profiles where appearance and manufacturability matter.

Are you ready to use 6063 aluminum for your project?

If you need high-quality aluminum extrusion, a smooth surface finish, and consistent performance, 6063 aluminum is a tried-and-true answer.

Honjenny specializes in custom aluminum extrusion, CNC machining, surface finishing, and precision fabrication from 6063 aluminum and other high-performance alloys.

Contact our skilled technical staff, who can assist you with selecting the appropriate temper, optimizing profile design, and ensuring consistent quality from prototype to mass production.