Aluminum (Al) items are well-valued for strength, lightness, and versatility. Still, you can’t miss the right surface finish. Otherwise, even the best aluminum parts fall short in durability and aesthetics.

Anodizing and powder coating remain two highly popular aluminum finishing methods. Each one comes with distinctive benefits with certain drawbacks to make things somewhat perplexed.

This article breaks down every crucial differentiating point between powder coating and anodizing. The details should help you confidently pick the ultimate surface finish for aluminum projects.

What Is Anodizing for Aluminum?

It transforms an aluminum surface into a durable oxide layer. The electrochemical process turns the finish into an integral Al part. Therefore, the thin layer isn’t some temporary metal surface coating.

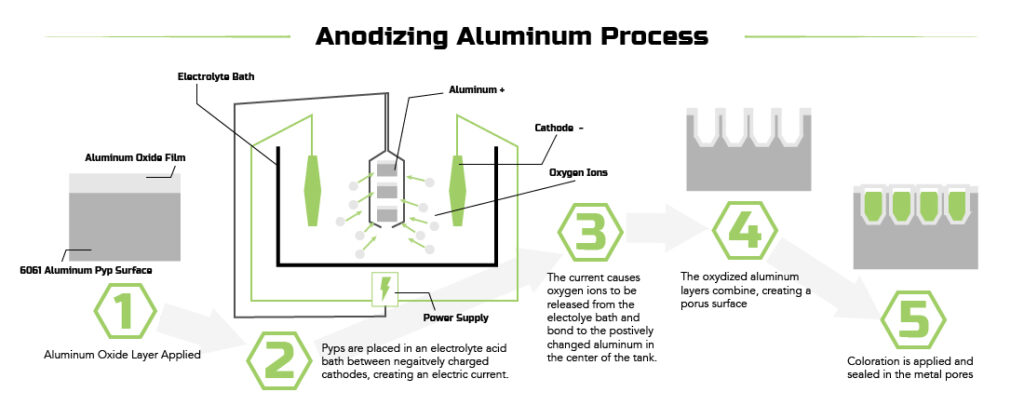

Anodized Coating Process: Step-by-Step Overview

- Cleaning and Etching the Aluminum: Thorough cleaning removes oils, dirt, and oxides. The part gets etched with an acid/alkaline-based electrolyte solution for proper adhesion.

- Immersion in Acid Electrolyte: The aluminum or aluminum alloys get submerged in an acid electrolyte bath (sulfuric acid). The aluminum acts as the anode in an electrical circuit.

- Electric Current Forms an Oxide Layer: A direct current is applied, causing oxygen ions to bond with the aluminum surface. It forms a thick, robust, and porous layer of aluminum oxide.

- Coloring and Sealing (Optional): The porous oxide layer can absorb dyes for decoration. The surface gets sealed using hot water or nickel acetate to close the pores after the coloring.

Characteristics of Anodized Coating

- Excellent Durability: Anodized aluminum boasts a wear-resistant surface. Type III anodizing (hard anodizing) can reach up to 60 Rockwell hardness for high-end applications.

- Corrosion Resistant: The oxide layer enables superb protection against corrosion. Anodized aluminum can withstand salt spray exposure for over 1,000 hours without degradation.

- Appearance: Anodizing produces a natural metallic sheen that can be left clear or dyed in vibrant colors. Apple’s MacBook finish is a real-world example of Al’s electrolyte bath in an anodizing tank.

- Thickness: The anodized layer ranges from 5 to 25 microns (µm) depending on the application. It’s 5 – 15 µm for décor, whereas the thickness gets to 15 – 25 µm for top-tier uses.

- Eco-Friendly: Anodizing is considered environmentally responsible. It emits minimal VOCs with non-toxic electrolytes. Even the finish is recyclable without heavy metals/hazardous waste.

Anodized Aluminum Applications

- Smartphone Frames: Apple, Samsung, and Huawei use anodized aluminum for smartphone bodies or frames. The finish offers a premium metallic sheen, resists fingerprints, and withstands daily wear.

- Architectural Panels: Anodized aluminum is a staple in curtain walls, façades, and window frames. Projects like the Burj Khalifa and One World Trade Center feature anodized panels for longevity.

- Optical Instruments: Precision instruments such as microscopes, telescopes, and camera housings use anodized Al. Black anodizing reduces glare for optical clarity in scientific and military-grade equipment.

- Marine Hardware: Anodized aluminum thrives in boat fittings, masts, cleats, and underwater housings. Scandinavian brands like Yamarin and Buster Boats use anodized aluminum for hull components.

What Is Powder Coating?

It involves applying powdered paint to the surface using electrostatic charge, followed by heat curing. The dry finishing approach contains no solvents to produce the thick yet uniform surface finish.

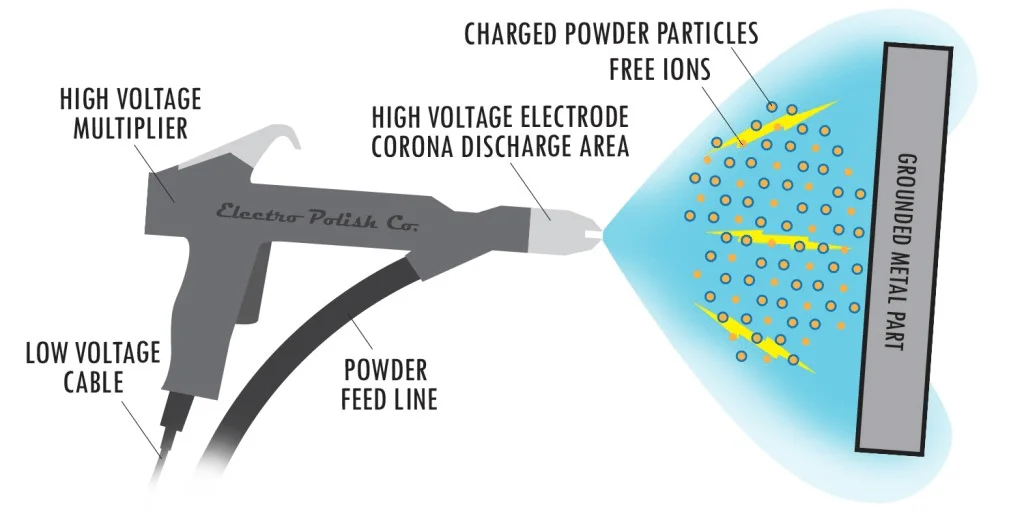

Powder Coating Process: Step-by-Step Overview

- Cleaning + Pre-treatment: The surface is cleaned to remove oils, dirt, and oxides for better adhesion. Pre-treatments include chemical etching or conversion coatings (like chromate or phosphate).

- Powder Application via Electrostatic Spray: A spray gun applies the powder using an electrostatic charge. The charged particles cling to the surface for a uniform coverage and minimal waste.

- Curing in an Oven (180°C – 200°C): The powder melts and chemically reacts to form a continuous film. Curing usually takes place for 10 – 20 minutes, based on the powder and the part.

- Cooling to Form a Uniform Finish: After curing, the part is cooled to solidify the coating into a hard layer, unlike other coatings. The underlying metal features a durable finish for aluminum products.

Characteristics of Powder-Coated Aluminum

- Durability: Powder-coated aluminum features an impact-resistant layer (60 to 120 microns) for high-traffic environments, outdoor structures, and industrial machinery.

- Color Variety: Powder coating offers an extensive palette of finishes. You can opt for glossy, matte, satin, metallic, pearlescent, textured, hammered, or wrinkle effects.

- Corrosion Resistance: Paired with proper pre-treatment, powder coating provides excellent corrosion protection. It’s particularly suitable for industrial or marine settings.

- Aesthetic Versatility: The highly customizable finish can serve many designs. Powder coating has uses across architectural façades, consumer electronics, and art installations.

- Environmental Benefits: Powder coating is a solvent-free process, emitting zero VOCs. Even overspray can be recycled to reduce potential waste and improve efficiency.

Powder-Coated (Architectural Applications and Beyond)

- Automotive Wheels: Powder-coated aluminum wheels offer chip-resistant finishes. Brands like BMW, Ford, and Tesla use powder coating for both aesthetic appeal and protection against road debris.

- Furniture: From patio sets to office chairs, powder-coated aluminum is prized for its resistance and flexibility. IKEA and other furniture brands use it to deliver vibrant and long-lasting finishes.

- Outdoor Lighting: Street lamps, garden fixtures, and architectural lighting feature them to resist fading and chalking. Cities like Dubai and Singapore use powder-coated products for public lighting infrastructure.

- Appliance Housings: Powder coating is common in refrigerators, ovens, and HVAC units. It’s used in industrial enclosures for electrical and mechanical systems, especially across North America.

Anodizing vs Powder Coating: Key Differences

- Wear Resistance (Durability)

The anodizing process creates a protective oxide layer as a part of the aluminum. Its abrasion resistance and less scratching in dry environments are identical to a natural oxide layer.

Powder coating, while thicker, forms a surface film that’s more vulnerable to impact damage. The uniform coating can chip or flake if struck or if the substrate wasn’t properly pre-treated.

However, the protective coating still performs better than liquid coatings with a thicker oxide layer. It’s better to deploy surface treatment for powder coating-based uses.

Figure 6 – Powder Coated vs Anodized Surfaces

- Corrosion Resistance

Anodized aluminum naturally resists corrosion through its self-sealing oxide layer. Proper sealing can withstand 1,000+ hours of salt spray testing to resist marine, coastal, and industrial harshness.

Powder coating provides excellent corrosion protection when the coating remains intact. Scratches, chips, or poor surface preparation can expose the base metal, making powder coating corroded.

- Environmental Impact

Anodizing is eco-friendly as it barely emits any VOCs (volatile organic compounds) while generating recyclable wastewater. The process relies on non-toxic electrolytes and minimal energy compared to thermal curing.

Powder coating also avoids VOCs and allows recycling of overspray. However, the high-temp curing process with ovens (180°C – 200°C) consumes more energy, increasing the carbon footprint.

- Maintenance and Lifespan

Anodized finishes are highly resistant to fading and wear under UV light in the surrounding environment. Its scratches are difficult to repair, as the oxide layer can’t be reapplied locally without re-anodizing.

Powder-coated surfaces are easy to clean and maintain. Still, they’re prone to peeling or bubbling that affects the metal products or metal parts. Touch-ups are possible, but color matching can be tricky.

- Aesthetics with Color Options

Anodizing offers a richer metallic appearance with translucent finishes. Color options are limited to earthy tones, silvers, bronzes, and blacks. The final hue can vary due to alloy composition and process.

Powder coating excels in aesthetic versatility. It supports hundreds of colors and effects with conventional paint. No wonder it has been the ideal choice for branded products, architectural façades, and consumer goods.

- Cost Considerations

Anodizing costs more per part due to chemical setup, masking, and precision control by default. Average pricing ranges from $2.50 – $5.00/ft² or €25 – €50/m².

Powder coating is more cost-effective for large volumes. Its prices range from $1.00 – $3.00/ft² or €10 – €30/m², with lower setup costs and faster turnaround for bulk production.

However, anodized finishes mostly outlast powder-coated counterparts in outdoor and high-wear cases. It reduces replacement and maintenance costs over time.

Summary Comparison: Powder Coating vs Anodized Aluminum

Choosing the Right Finish: Powder Coated vs Anodized

Likewise, selecting between anodizing and powder coating is the ultimate goal here. And it depends on your project’s environment, performance demands, and visual goals.

- When to Choose Anodizing

Anodizing is the go-to finish when your aluminum parts face harsh environments, mechanical wear, or require a sleek metallic look.

- Architectural elements (curtain walls, window frames, and cladding) in coastal or high-sunlight regions.

- Marine hardware, such as boat fittings, masts, and underwater housings exposed to saltwater.

- Highly durable aerospace components, including aircraft skins, brackets, and control surfaces.

- When to Choose Powder Coating

Powder coating shines when color variety, branding, and design flexibility are top priorities. It’s perfect for consumer-facing products and decorative applications.

- Consumer electronics and appliances like refrigerators, ovens, and HVAC units.

- Automotive parts such as wheels, trim, and underbody components.

- Furniture and outdoor lighting where vibrant finishes and weather resistance are needed.

Dual Finishing: Anodizing Powder Coating

Some manufacturers use a hybrid approach. They apply anodizing for corrosion resistance, followed by powder coating for color and texture. You can expect –

- Enhanced durability: Anodizing protects the base metal even if the powder coat chips.

- Improved corrosion resistance: Ideal for coastal architecture and industrial machinery.

- Design flexibility: Powder coating adds branding and visuals on top of the anodized base.

However, dual finishing increases initial costs due to added processing steps. It can still reduce long-term maintenance and replacement costs.

Standards for Anodizing and Powder Coating

a. Anodizing Standards

- ISO 7599 – It specifies requirements for decorative and protective layer (anodic oxidation coatings) on aluminum. The regulations cover thickness, sealing quality, and color uniformity.

- ASTM B580 – It defines coating classes (decorative, protective, hard) and corresponding thicknesses. The regulations include corrosion resistance and abrasion testing.

- MIL-A-8625 – It defines a broad spectrum of military uses via Type I, Type II, and Type III anodizing. The regulations specify sealing, corrosion resistance, and electrical conductivity.

b. Powder Coating Standards

- AAMA 2604 / 2605 – AAMA 2604 regulates high-performance coatings with 5-year color retention. And AAMA 2605 specifies superior performance with 10+ years of durability and UV resistance.

- ISO 8130 – It covers flow properties, particle size distribution, film thickness, and curing behavior. The regulations enable consistency in application and performance across global markets.

Frequently Asked Questions (FAQs)

- Can you anodize aluminum after powder coating?

No. Powder coating creates a sealed surface that prevents the electrochemical reaction required for anodizing. Anodizing must be done first when combining both finishes.

- Which finish is easier to clean: anodized or powder-coated aluminum?

Powder-coated surfaces are easy to clean with mild detergent due to their smooth and sealed finish. Anodized surfaces may require non-abrasive cleaners to avoid dulling the metallic sheen.

- Is either of the two finishing fire-resistant or heat-tolerant?

Anodized aluminum withstands higher temperatures (up to 500°C) without degrading. Powder coating may degrade or discolor above 200°C, depending on the resin type.

- Which finish offers better chemical resistance?

Anodizing generally offers better resistance to acids and solvents. Powder coating can resist mild chemicals but may degrade with strong solvents or prolonged exposure.

- Can either finish be used on cast aluminum?

Powder coating is preferred for cast aluminum due to its porosity. Anodizing may result in uneven finishes or poor sealing on cast surfaces unless specially treated.

- Does anodizing affect aluminum’s mechanical properties?

No. Anodizing only alters the exterior surface. It does not affect the tensile strength, ductility, or fatigue resistance of the base metal.

Conclusion

Choosing the right option between anodizing and powder coating shouldn’t be troublesome. Both finishes offer powerful protection for aluminum, but they shine in different ways. The smartest choice lies in your project requirements and, more specifically, intended applications.

Precise Aluminum Surface Finishing at HONJENNY

Honjenny has been a top aluminum brand, partly due to our high-quality surface finishes. We have been here with innovation, commitment, and precision for 30 years. Contact us to know further.