It is common knowledge about die cast alloys that they behave differently when anodised. This mostly results in uneven finishing with costly rejections. But this won’t be a problem anymore. Read our detailed guide, breaking down the problems and best practices for anodizing aluminum. By the end, you’ll become an expert in anodizing aluminum castings.

What Is Anodized Cast Aluminum?

Anodized die-cast aluminum refers to any die-cast aluminum component that has undergone the process of anodizing. Such a component has undergone the electrochemical process of anodizing. This process converts the surface into a controlled layer of aluminum oxide. This layer, contrary to what many think, is not a coating. Rather, it becomes a part of the metal surface. This improves the overall durability of the component and provides protection.

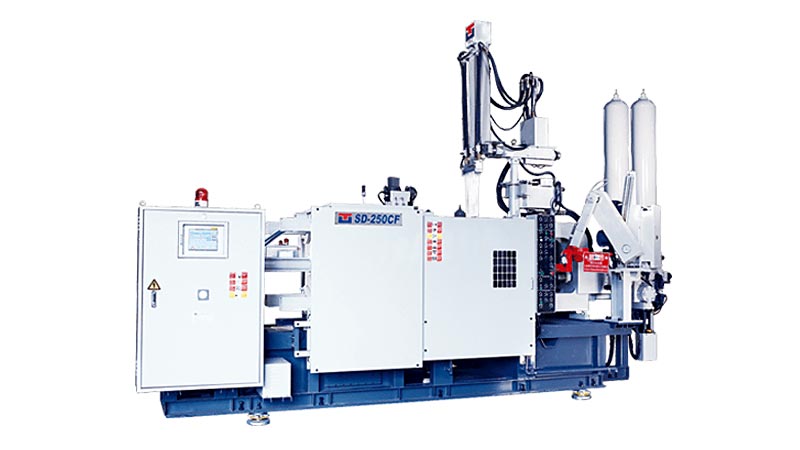

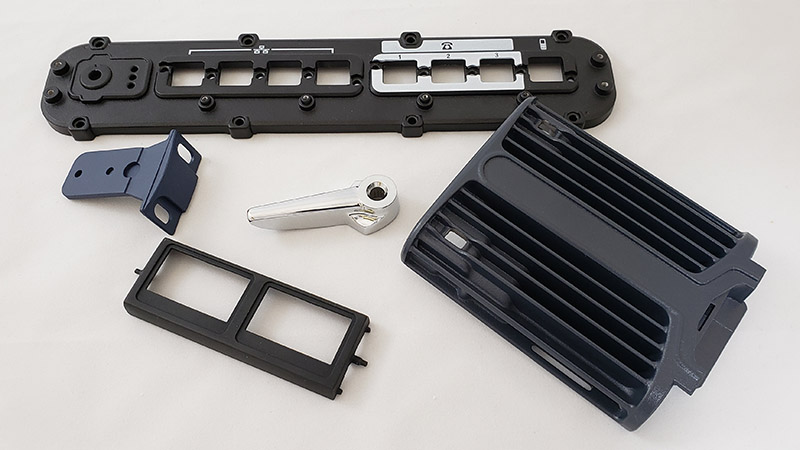

Contextually, die cast aluminum mainly means pressure die-cast aluminum parts. These parts are commonly used for high-tech and complex components. These are different from extruded or wrought aluminum. This is because they contain higher levels of silicon and other elements, which makes their anodizing difficult.

Even when it’s a form of anodized aluminum alloy, die cast aluminum behaves differently during processing. Because of this, achieving uniform thickness, colour, and surface finishing gets tough. It is only possible with tight control of the process. It’s best to set realistic expectations when anodizing die cast aluminum compared to other extrusions.

Why Anodizing Cast Aluminum Matters?

Anodizing die-cast aluminum makes it stronger, more durable, and gives it a good finish. The process also makes aluminum strongly resistant to corrosion. Thus, it protects it from scratches, wear and tear, as well as electrical issues.

For everyday usage, anodizing die cast aluminum gives it a premium and long-lasting look. This makes it ideal for decorative, automotive, and consumer electronic parts.

Realistically, anodizing is a tricky process. However, it is still preferred because of its ability to combine complex shapes with a long-lasting finish. The kind of finishing anodizing gives is something simply not achievable by painting or coating.

Benefits of Anodized Die Cast Aluminum Parts

There are several benefits of anodizing aluminum castings, some of which include the following:

- Improved corrosion resistance, which protects parts in salty, humid, and outdoor environments.

- Electrical insulation, which offers great protection to sensitive components.

- Better wear and scratch resistance, which makes aluminum components hard and durable. This gives them longevity.

- Aesthetic flexibility, which comes with metallic finishing, colours, and textures. This gives the components a premium look and fade resistance.

Why Prefer Anodizing over Painting or Powder Coating?

Painting and powder coating often can’t achieve the results that anodizing gives. Metallic paint often can’t give aluminum the thin, hardened metallic feel. Paint and powder coating can chip, peel, or look plastic-like. Compared to these, anodized coating is ideal when durability and a true metallic finish are required.

Can Die Cast Aluminum Be Anodized? Key Challenges

Certainly, die-cast aluminum can be anodized. However, it is much more challenging than anodizing only the aluminum or aluminum alloys. These include aluminum zinc alloys, aluminum magnesium alloys, and aluminum silicon alloys.

There are several challenges associated with the aluminum anodizing process. These include inconsistent finishing, being at the top. Unless proper care is taken, anodizing often results in an uneven, patchy anodized finish. There are dark grey finishing that has spots and blisters on them. Sometimes, the dye absorbs poorly, which also leads to a streaky finish and abruptly thicker coatings.

Mostly, these issues are caused by high porosity, trapped gases in the casting, as well as high impurity or silicon content in the alloy. Rough surface textures from the die casting also lead to improper anodizing results.

However, it is very easy to mitigate these challenges through carefully choosing the alloy and optimising the part design. Pre-treatment and precise control during the anodizing process are important. These allow manufacturers to achieve great anodizing results on even the most complex die-cast shapes.

Anodizing Process for Die Cast Aluminum: Step-by-Step

The anodizing process for die cast aluminum is not very lengthy. However, proper care must be taken at each stage to avoid ending up with a rough finish of the anodized aluminum parts. Below are the steps to follow to anodize aluminum die-cast surfaces.

Step 1: Surface Preparation

Preparing the surface of the die cast is the defining stage of the anodizing process. This can be done by cleaning and degreasing the surface to remove oils. It is also important to clear mould-releasing agents and other fluids.

Then, following the process of etching, smooth the surface to remove aluminum oxide scales in a controlled manner.

Lastly, de-smutting helps remove residual silicon impurities, iron, and copper. Ensuring proper cleaning helps avoid streaky, uneven, and weak finishes.

Step 2: Anodizing Aluminum

At this stage, the component is placed as an anode in an acid bath. Here, a controlled current builds the oxide layer on the aluminum component. Taking care of bath chemistry, temperature, density, and time helps ensure proper anodizing and creates a nice oxide layer.

Step 3: Coloring, Sealing, and Post-Treatment

Once the anodizing is done, the last step is to give the final touches to the component. It begins with coloring the anodized component using organic dyes or the method of electrolytic coloring.

After this, the component’s surface is sealed using hot water, nickel acetate, or advanced sealants. Sealing helps close the pores and improve corrosion resistance and color retention of the component. Coloring options include using electrolytic methods or organic dyes.

Post-treatment includes powder coating. It can be applied if you want extra protection for your die-cast component or want it to look aesthetically appealing.

Materials & Alloy Selection for Anodizing Die Cast Aluminum

Commonly, die-cast alloys, including ADC12, A380, and A360, are formulated to improve the melt flow and casting productivity of the die casting process. However, using these alloys often produces dark and uneven finishing. This limits the decorative use of the component. If you are not concerned with surface appearance, going for these alloys is a good idea.

There are some other suitable anodizing alloys that ensure proper surface appearance. These include AL-MG and AL-MG-Si groups. Make sure to control the casting quality. Low porosity, controlled shrinkage, and good die design help reduce surface defects. These measures also ensure proper aesthetic finishes.

It is also important to conduct a quick suitability check before selecting any alloy. This can be done by asking yourself a simple question. Ask whether you want an aluminum die-cast with a premium decorative look or simply want it to perform functionally.

You also need to see if you are using a high-silicon alloy or something that is anodizing-friendly. If you need a glossy finish, consider other alternatives, but for robust functional usage, anodizing alone is a good option.

Common Problems and Solutions in Anodizing Die Cast Aluminum

The trapped gases in die-cast parts can often lead to blistered and streaky finishes with patchy anodized films. The solution is to improve the casting process by using vacuum die-casting. You can also apply vacuum impregnation whenever needed.

It is also important to prepare the surface properly by cleaning it of any impurities. Control etching and ensure proper sealing conditions to avoid streaks and blisters.

Sometimes, the anodizing process results in dark and patchy colours. This is because high silicon, iron, and other impurities interfere with oxide growth. This leads to cloudy finishes.

The solution is to properly re-specify alloys for critical cosmetic parts. It is also important to optimise de-smutting and bath control. One must understand that some die-cast parts can never achieve a silvery finish.

Sometimes, you notice fading colours, blotchy designs, and corrosion on the anodized component. It is because of poor dye absorption and sealing issues. The solution is to ensure proper oxide thickness and adjust dye parameters. Along with this, try using proper sealing methods.

Best Practices & Design Tips for Successful Anodizing

Good anodizing begins with the design stage of the die-cast aluminum component. The component should not have extremely sharp edges or small radii. This can result in burning and thin coatings. There shouldn’t be deep blind holes and hard-to-rinse areas where the trapped chemicals can ruin process efficiency.

Anodizers must be given proper markings on critical cosmetic surfaces that require appeal and high-tolerance areas. This way, they know where control matters more. By making small design adjustments, you can affordably achieve proper anodizing finish.

For engineers and buyers, it is best to run sample trials before committing to bulk production. Be clear about coating thickness, color tolerance, and test standards. After this, you can go on to finalising your anodizing orders.

Consistent pretreatment, bath maintenance, and routine quality checks are also important. These help ensure proper results for die-cast aluminum components.

Conclusion

Although it’s a bit difficult, successful anodizing of die-cast aluminum is achievable. Just make sure to use the right kind of alloy. Also, follow proper precautions throughout the process.

When done correctly, anodizing provides balanced aesthetics and durability to any die-cast aluminum. This makes it ideal for a range of applications. Always make sure to choose the right manufacturer or supplier of aluminum die casting to ensure proper results.

Let Honjenny Help You With Anodizing Aluminum – Get A Free Quote Today!

Working on current or upcoming die-cast aluminum projects? Want expert help or an opinion? The experts at Honjenny are here to help. With years of experience, we are your one-stop solution for all your Aluminum die cast needs.

Reach out to us today for a consultation. Get expert component designs, selection tips, part design, and surface treatment input. We can serve all your individual as well as bulk production needs.