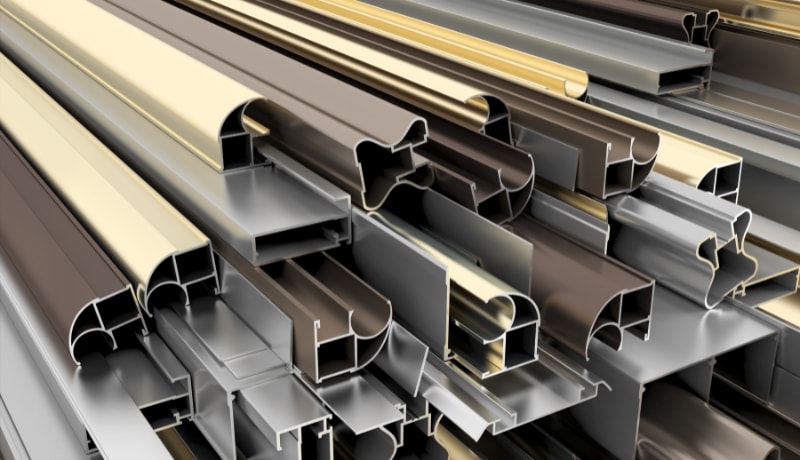

Aluminum profile bending is a vital manufacturing process for creating smooth curves, arcs, and detailed shapes from straight aluminum extrusions. Curved aluminum profiles are used in building facades, window frames, car bodies, and the industrial sector. This guide explains what aluminum extrusion bending means, the materials involved, the bending process, and design guidelines.

What is Aluminum Profile Bending

Aluminum profile bending (also called aluminum extrusion bending) is the process of forming straight extruded profiles into a specified radius or shape using controlled mechanical force. Bending instead of cutting and welding many straight parts gives manufacturers the ability to create continuous, smooth curves with higher strength and appearance.

Bending is done without melting the aluminum. The outer part of the bend is put under tension, and the inner part is compressed. Strict management of force, tooling, choice of alloy, and temper is required to prevent the occurrence of defects in the form of cracking or wrinkling.

Which aluminum materials are suitable for bending?

Not every aluminum alloy has an identical bending behavior. The flexibility of aluminum is determined by the composition of the alloy and temper.

Overall, aluminum alloys that have low strengths and high ductility are readily bendable. The 6xx series aluminum alloys, particularly 6063 and 6061, are commonly extrusion-bent with a good balance of formability, strength, and corrosion resistance.

Generally, 3003, 5052, 6061, and 6063 are also very good in bending processes, although this depends on the proper temper chosen according to industry standards. Soft temper is readily bent, while harder temper requires a greater radius or specialized tools.

Main Methods for Bending Aluminum Extrusions

Various bending processes vary with the profile shape, bend radius, accuracy level, and volume of production.

Roller Bending

Roll bending involves the application of three or more rollers to bend the aluminum profile as it moves through the machine. The pressure is introduced gradually, thereby decreasing stress and deformation.

- Applicable to: Large radii, long profiles, and architectural curves.

- Benefits: Continuous curves, minimal cost of tools.

- Limitations: Less accurate with a small radius.

Ram Bending

The aluminum profile is forced into the fixed die through a hydraulic ram, which is known as ram bending. The curve has only one point of bend.

- Best for: Simple bends, small batches, and thicker profiles.

- Pros: Easy to install, inexpensive.

- Limitations: Increased risk of distortion and springback.

Rotary Draw Bending

Rotary draw bending is a process that uses a rotating bend die and a clamp to wraps the profile around a bend die to achieve a consistent radius. Hollow profiles are typically bent using mandrels to avoid collapses.

- Applicable to: Tight radii and high precision.

- Pros: High precision, reproducibility.

- Limitations: Increased tooling cost.

Compression Bending

During compression bending, a pressure arm is applied to the profile, with the profile being squeezed into shape between a fixed die.

- Applicable to: Symmetrical profiles, ornamental use.

- Pros: High-quality surfaces.

- Limitations: Poor radius control.

Stretch Bending

Stretch bending is performed by exerting pressure on the aluminum profile as it is bent around a shape. The stretching minimizes springback and wrinkling.

- Applicable to: Large, smooth curves

- Pros: Dimensional accuracy is high.

- Limitations: Longer material length required.

Free-Form Bending

Free-form bending is the technique used by CNC-controlled bending machines to produce multi-radial, 3D-shapes without fixed bending dies.

- Applicable to: Custom and complicated geometries.

- Pros: Maximum design freedom.

- Limitations: More expensive and more complex to set up.

Comparison Table: Which Bending Method Is Best?

The thickness of your material, the level of precision you need, and the volume of production all play a major role in selecting the best bending technique.

Common Bending Defects & How to Prevent Them

Aluminum bending can also be defective even when the appropriate method is used without good control.

Wrinkling (Buckling)

Compressive stress causes wrinkling on the inner radius of the bend.

Prevention tips:

- Hollow profiles are to be used with mandrels.

- Increase bend radius.

- Use stretch bending to balance the stress.

Cracking

The cracks form on the outer radius where the material experiences tension.

Prevention tips:

- Use softer tempers (T4 or O).

- Use more ductile alloys such as 6063 aluminum.

- Do not use excessively narrow bend radii.

Springback

Springback occurs as aluminum attempts to revert to its straight natural form following the process of bending.

Prevention tips:

- Compensate by over-bending by bending tool slightly.

- Use stretch bending.

- Use heat after bending where necessary.

Selecting the Right Alloy and Temper for Bending

The appropriate bending of the aluminum alloy and temper is important in the selection.

The Best Alloy

The best choice for bending is alloy 6063. Its good strength, coupled with its formability and aluminum surface finish, qualifies it as an ideal material that can be used in architectural and decorative works.

The alloy flows easily without being cracked or wrinkled. It is also anodized well, and the finished appearance is very appealing after bending.

Knowing Temper Designations.

The aluminum temper designation shows the way the aluminum has been processed following extrusion. This has an enormous influence on bendability.

T5 and T6 tempers are hard and strong. Artificial aging of the aluminum was done in order to enhance strength. Nevertheless, this hardening decreases the formability. T6 material is difficult to bend and needs more radii to prevent cracking.

T4 temper is soft and formable. The aluminum was not artificially aged, although it was solution heat-treated. It also bends significantly easier than T6 material, and it allows tighter radius bends to be made without breaking.

The T4-to-T62 Strategy

To bend tight bends on the 6000 series alloys, this is an innovative technique: heat the profile by holding it in T4 form when it is soft and pliable. Bend and artificially age the part to T6-strength levels. The resultant temper is denoted T62.

It is the best of both worlds, such easy bending and then high strength in the finished product. The technique is applied by most manufacturers in the case of architectural elements where tight bends and strength are needed.

Design Guidelines: Minimum Bending Radius

The tightest radius of bending is used to calculate how tightly you can bend aluminum without defects.

The Wall Factor

In hollow cross-sectional objects, such as tubes, the wall thickness is divided by the overall diameter, which is referred to as the wall factor. Tubes with a high wall factor (thick-walled tubes) bend more readily than the skinny ones. Unless walls are well supported internally, they are inclined to collapse or wrinkle.

Standard Bend Radii

The 3D or three times the diameter, or the width of the profile, is a safe standard in most applications. Such a radius reduces stress and delivers a little special tooling or reliable results. There are numerous 3D bends that are applied structurally.

Stricter bends of 1.5D or the use of specialized equipment could be done. Tube tight-Radius bending is done by rotary draw bending with mandrels to support the inner wall of tubes. The mandrel makes the tube unable to collapse so that the shape is kept. Custom tooling is more expensive but necessary only when designs require dramatic curves.

In the case of solid profiles, the radius of the minimum bend is determined by alloy and thickness. The thicker sections require larger radii, as a rule. It is always important to converse with your supplier of bending early in your design process so that what you need is within your specifications.

Where Is Aluminum Profile Bending Used?

Aluminum profile bending finds application in most industries, such as:

Automobile: Chassis parts, roll bars, exhausts, and body parts.

Architecture: Curved window frames, building facades, handrails, and canopies.

Aerospace: Aircraft seat frames, structural parts, and interior parts.

Signage: Display frames, display letters, and custom shapes.

Sports: Bikes, exercise devices, and athletic goods.

Furniture: Chair frames and table bases, as well as ornamentation.

Marine: Marine railings, frame elements, and hardware.

Transportation: Interiors of buses and trains, grab handles, and structural frames.

FAQs

Does the aluminum extrusion bending project work for all alloys?

The majority of the extrusions are bendable, but the success is dependent upon alloy, temper, profile shape, and radius of bending.

Do you think bending is superior to welding curved?

Yes. The result of bending is continuous curves that are stronger, have a better appearance, and can resist corrosion.

Which is the most accurate way of bending?

Rotary draw bending and stretch bending offer the greatest degree of accuracy.

Conclusion

Aluminum profile bending is the most effective technique for producing powerful, smooth, and aesthetically captivating curved aluminum extrusions.

The manufacturers are able to get exact results with minimum defects by selecting the appropriate alloy, temper, techniques of bending, and the radius of design. These fundamentals will aid in lessening the expenses, enhancing quality, and broadening the design opportunities.

Partner with Honjenny for Aluminum Extrusion Solutions!

Honjenny helps a variety of sectors, including construction, transportation, electronics, and precision manufacturing, from conception to production. With the support of skilled engineers and stringent quality standards, we are capable of aluminum extrusion, CNC machining, aluminum die casting, and sophisticated surface treatments.

Get a customized quote by contacting our team right now to discuss your design, material needs, or manufacturing objectives.