Global supply chains in the modern world thrive via guaranteed consistency and repeatable quality. The tiniest deviation can ripple across production networks, causing costly delays and compliance failures.

That’s where Production Part Approval Process (PPAP) enters the frame as the industry’s safeguard. PPAP standardizes the demonstration of parts to meet customer specs before full-scale production.

PPAP remains non-negotiable for applications involving dimensional accuracy and reliability. The guide breaks down its meaning, levels, process, and submission requirements to define a clear roadmap.

PPAP Process: Production Part Approval Process

Short Answer: PAP is a standard process used by almost all manufacturers involved in a global supply chain. It proves manufacturers are consistently producing parts that meet the project specifications.

- PPAP is a framework to establish confidence that a supplier’s production process can reliably meet the engineering design based on the customer-specific requirements before initiating mass production.

- PPAP sits within the APQP family of methods with common terminology + forms to document readiness, capability, and evidence of conformance during an actual production run at the quoted rate.

- PPAP principles are now widely practiced across high-end manufacturing process (aerospace, military). The statistical process control reduces defects, clarifies expectations, and strengthens customer–supplier trust.

PPAP within IATF 16949 Quality Systems

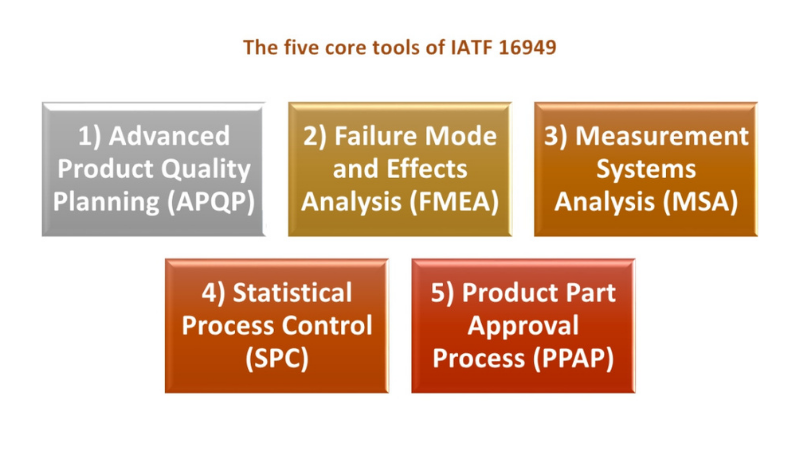

Five “Core Tools” within IATF 16949 underpin automotive quality systems – APQP, FMEA, PPAP, MSA, and SPC. PPAP gets activated in APQP’s ‘Product and Process Validation phase’.

PPAP, as a QMS mechanism, provides objective evidence that every aspect of product design and manufacturing has been validated prior to launch, integrating with FMEA + MSA +SPC.

PPAP verifies that the supplier process consistently meets customer requirements through documented evidence. And the samples for testing come from actual production parts instead of prototypes.

Why PPAP is Important for Die Casting Manufacturers?

PPAP in die casting manufacturing ensures dimensional accuracy, repeatable quality, and professional documentation. Each factor is directly attributed to trustworthiness toward global customers.

- In aluminum die casting, PPAP ensures porosity control, dimensional stability, and surface finish consistency. They’re critical for engine housings, transmission cases, and lightweight structural parts.

- In zinc die casting, PPAP confirms precision in small, complex geometries such as connectors, housings, and decorative components. In such cases, cosmetic and functional accuracy are equally important.

How PPAP Helps Die-Cast Suppliers?

- Launch Readiness: A disciplined PPAP process prevents costly delays. Poor PPAP submissions can push projects weeks behind schedule, while robust PPAP accelerates SOP (Start of Production) with a design verification plan for quality control checks.

- Process Stability: PPAP requirements include evidence from actual production runs. Thus, it ensures that machines, molds, and inspection systems are stable before scaling up.

- Customer Confidence: Buyers increasingly demand PPAP compliance to confirm suppliers can deliver zero-defect parts consistently, regardless of the supplier’s manufacturing location. Global OEMs reject suppliers who can’t provide PPAP documentation.

- Traceability: PPAP requires detailed records (material certifications, dimensional reports, capability studies, and control plans). It creates a traceable chain of accountability.

Key PPAP Documentation Requirements

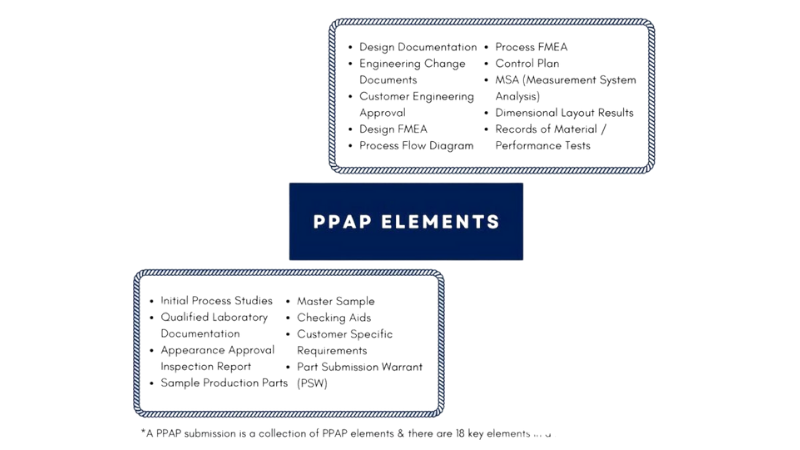

The Production Part Approval Process (PPAP) is built around a documentation package. Those docs mark the start of compliance across industries.

Standard PPAP Package Components

- Design Records: The official drawings and specifications provided by the customer. They serve as the baseline against which all dimensional and performance checks are validated.

- Engineering Change Notice/Documents: Records of any approved design or process changes. Critical for traceability, ensuring that suppliers and customers align on revisions.

- DFMEA / PFMEA (Design and Process Failure Mode and Effects Analysis): Structured risk analysis tools identifying potential failure modes. DFMEA focuses on design risks; PFMEA addresses process risks.

- Control Plan: A detailed roadmap of how the process will be controlled to maintain product quality. Includes inspection points, measurement methods, and reaction plans.

- MSA (Measurement System Analysis): Validates that inspection and measurement systems are accurate and repeatable. Ensures that data used for decision-making is reliable.

- Dimensional Report: Confirms that part dimensions match design records. It’s critical to handle shrinkage, warpage, and tolerance challenges in aluminum die casting.

- Material Test Results: Qualified laboratory documentation verifies material properties. Test performed in die casting confirms alloy composition, hardness, and tensile strength.

- Initial Sample Inspection Report (ISIR): Documents inspection results from the first production run. Initial process studies provide early evidence of conformity before scaling up.

- Capability Studies: Statistical evidence (Cp, Cpk indices) showing process stability and capability. For die casting, capability indices often focus on porosity levels, dimensional accuracy, and surface finish.

- Appearance Approval Report: Ensures cosmetic specs (surface finish, color, texture) of quality parts. The customer engineering department gets a detailed description from the PPAP manual.

- Sample Production Parts: Physical parts submitted for customer engineering approval. Often retained for comparison during audits.

- Master Samples: Approved reference parts kept by both supplier and customer. Used to validate future production consistency.

- Checking Aids: Fixtures, gauges, or tools used for inspection. The critical processes must be documented and calibrated to ensure accuracy.

- Appearance Approval Report (AAR): Formal documentation of cosmetic approval, often required for visible components.

Emphasis on Level 3 Documentation

Level 3 is the most common within PPAP submission levels, with all documentation + final product samples. It provides full evidence of compliance, making it the default expectation for most OEMs.

Components affecting appearance may require new or revised parts based on the key elements. Completing validation testing needs measurement equipment upon a comprehensive risk assessment.

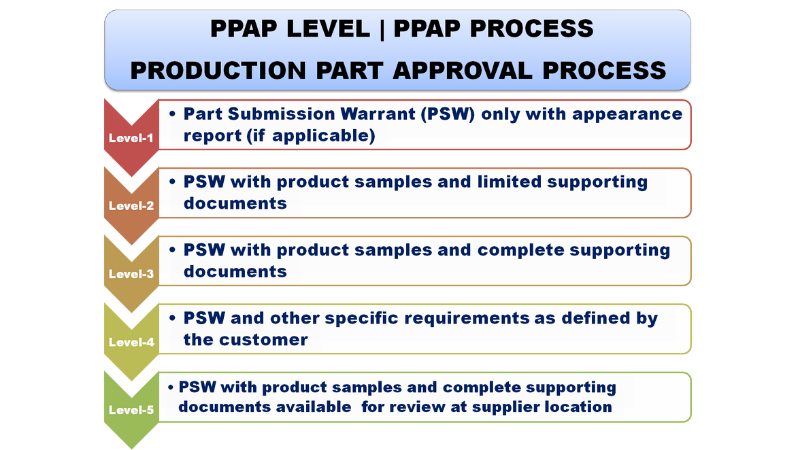

PPAP Levels (Level 1 – Level 5)

PPAP levels define how much documentation and evidence a supplier must provide to prove that their production process consistently meets customer requirements.

Level 1 – Part Submission Warrant (PSW) Only

Supplier submits only the PSW, a formal declaration that parts meet requirements.

Use case: Low-risk parts, simple components, or when the customer has high confidence in the supplier.

Even if only PSW is submitted, suppliers should internally maintain full PPAP documentation for audits.

Level 2 – Part Submission Warrant (PSW) + Limited Supporting Data

PSW plus selected documents (dimensional results, material certifications).

Use case: Moderate risk parts where limited verification works based on a limited supporting data level.

European OEMs request Level 2 for cosmetic parts where appearance matters.

Level 3 – The Industry Standard (Most Common)

PSW plus complete supporting data and sample parts.

Default requirement for most automotive and aerospace industries.

Over 70% of PPAP submissions globally are Level 3.

Treat Level 3 as the baseline; suppliers who master it gain credibility.

Level 4 – Submission as Agreed with Customer

Flexible level where requirements are negotiated between the supplier and customer.

Use case: Unique projects, rapid prototypes, or advanced technology parts.

Level 4 is used in collaborative innovation projects, where documentation evolves with design maturity.

Level 5 – PSW + Complete Documentation Reviewed On Site

PSW plus full PPAP package, reviewed at the supplier’s facility.

Use case: High-risk, safety-critical parts, assembly process, or new suppliers.

Japanese OEMs frequently require Level 5 for safety-critical parts.

Prepare for Level 5 by maintaining audit-ready documentation.

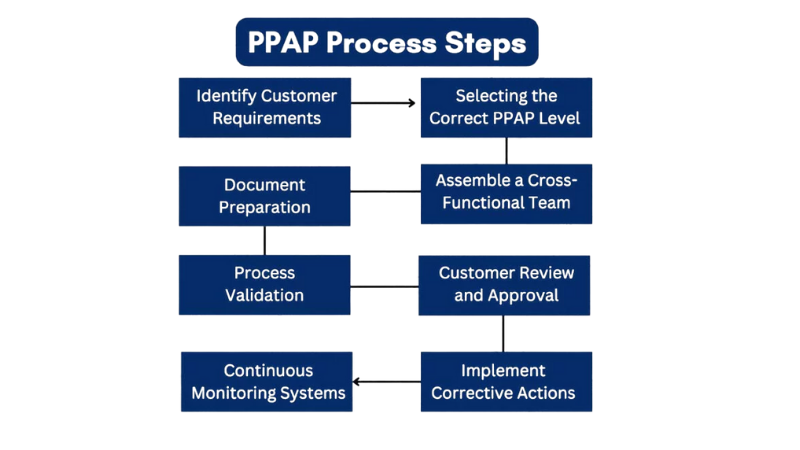

Step-by-Step: Entire PPAP Submission Process Flow Diagram

Step 1 – Design and Requirements Review

Objective: Align supplier and customer expectations by reviewing design records, specifications, and customer requirements.

Activities: Study engineering drawings, CAD models, and material specifications. Identify critical characteristics (safety, regulatory, cosmetic). Review customer-specific requirements (CSR) under IATF 16949.

Step 2 – Process Planning

Objective: Develop a robust manufacturing and advanced product quality planning before production.

Activities: Conduct PFMEA (Process Failure Mode and Effects Analysis) to identify risks. Draft a Control Plan detailing inspection points, measurement methods, and reaction plans. Validate tooling, gauges, and checking aids.

Step 3 – Sample Production with Dimensional Results

Objective: Run actual production using standard equipment, tooling, and operators at quoted rates.

Activities: Produce initial sample parts under normal operating conditions. Document parameters (temperature, cycle time, pressure) related to the entire process.

Step 4 – Measurement System Analysis and Data Collection

Objective: Collect evidence that parts meet dimensional, material, and performance requirements.

Activities: Perform Dimensional Reports comparing parts to design records. Conduct Material Tests (hardness, tensile strength, metallurgical composition). Execute Capability Studies (Cp, Cpk) to prove statistical stability. Validate MSA (Measurement System Analysis) for inspection tools.

Step 5 – Submit PPAP Package upon Process Validation

Objective: Deliver the PPAP documentation package to the customer.

Activities: Compile required elements (PSW, FMEA, Control Plan, Dimensional Reports, Material Tests, ISIR, etc.). Submission level (1–5) depends on customer requirements, with Level 3 being most common.

Step 6 – Customer Review of Master Sample for PPAP Approval

Objective: Obtain formal customer approval before mass production.

Activities: Customer quality engineers review documentation and sample parts. For Level 5 PPAP, customers may conduct on-site audits of processes and documentation.

Common PPAP Challenges (Process Failure Mode)

A design failure mode almost always traces back to weak evidence and poor control. Some of the most frequent pitfalls are listed below with precise ways to prevent them.

- Incomplete Dimensional Data

Cause: Sampling from prototypes, missing critical characteristics, or not measuring at quoted production rates.

Risks: Rejections, rework, and delayed SOP due to unverified fit/function.

Fixation (How to Resolve) –

- Full Coverage: Map every drawing feature to a measurement method in your control plan and ensure 100% reporting for critical characteristics.

- Production-Run Evidence: Measure parts produced on normal equipment, tools, and operators at the quoted rate.

- Traceability: Include ballooned drawings, feature IDs, and lot/date codes to link results to actual parts.

- Capability Indices Below Acceptable Limits

Cause: Unstable process, insufficient sample size, or inappropriate spec/measurement strategy.

Risks: Increased scrap, escapes, and escalations to higher PPAP levels.

Fixation (How to Resolve) –

- Stability First: Use SPC to detect and eliminate special causes before calculating capability.

- Right Metrics: Target Cp/Cpk thresholds agreed with the customer; increase sample size and rational subgroups for trustworthy indices.

- Process Improvements: Tighten tooling maintenance, optimize cycle parameters, and add mistake-proofing for critical features.

- Missing Calibration Records

Cause: Lapsed gauge calibration, incomplete certificates, or undocumented checking aids.

Risks: Data invalidation and audit nonconformity with the intended nominal value for quality requirements.

Fixation (How to Resolve) –

- Calibration Discipline: Maintain current certificates for all gauges, fixtures, and checking aids referenced in PPAP.

- MSA Linkage: Include Gage R&R or attribute agreement for critical measurements to prove repeatability and reproducibility.

- Labeling and Control: Tag assets with calibration due dates; lock out-of-calibration gauges from use.

- Outdated FMEA or Control Plan

Cause: Engineering changes not cascaded, lessons learned not integrated, or siloed ownership.

Risks: Undetected failure modes, weak controls, and customer escalations.

Fixation (How to Resolve) –

- Closed-Loop Updates: Trigger FMEA and control plan revisions for any design/process change, nonconformity, or customer feedback.

- Cross-Functional Review: Involve engineering, quality, production, and maintenance to capture real risks and effective controls.

- Evidence Trail: Version-control documents, noting change rationale and dates to demonstrate traceability.

- Poor Documentation Formatting

Cause: Inconsistent templates, missing signatures, and disorganized files.

Risks: Prolonged reviews, resubmissions, and perceived lack of professionalism.

Fixation (How to Resolve) –

- Standardized Templates: Use clean, customer-aligned formats for PSW, dimensional reports, MSA, FMEA, and control plans.

- Submission Checklist: Validate completeness, page references, and index against the agreed PPAP level (Level 3 usually requires the full package).

- Visual Clarity: Ballooned drawings, clear tables, and page numbering enable fast customer verification.

- Material Composition Discrepancies in Die Casting Alloys

Cause: Alloy variation, contaminated melt, or supplier mix-ups.

Risks: Mechanical property failures, porosity spikes, and functional/cosmetic defects.

Fixation (How to Resolve) –

- Incoming Verification: Test alloy composition against standards (for aluminum series and zinc grades) and retain certificates.

- Melt Control: Monitor temperature, fluxing, and degassing; track lot numbers through casting, CNC machining, and finishing.

- Property Validation: Include hardness, tensile tests, and microstructure checks; correlate results with porosity and dimensional stability.

PPAP Software and Digital Documentation Tools

Digital transformation is reshaping how suppliers manage the Production Part Approval Process (PPAP). Modern PPAP software solutions streamline workflows, reduce errors, and enhance traceability.

- Digital PSW (Part Submission Warrant)

Digital PSW platforms now allow suppliers to generate, sign, and submit PSWs electronically. Benefits include faster approvals, version control, and integration with ERP/QMS systems.

- Automated Data Collection

Modern PPAP tools integrate with shop-floor systems (MES, SPC software, CMM machines) to automatically collect dimensional, material, and capability data. It eliminates manual transcription errors and ensures real-time accuracy.

- AI-Based Dimensional Deviation Analysis

AI algorithms can analyze dimensional data from CMMs or scanners to detect deviations early. Predictive analytics highlight trends before they become nonconformities, improving first-pass yield.

Frequently Asked Questions (FAQs)

- Who requires PPAP submission approval?

PPAP is required by auto OEMs under Automotive Industry Action Group (AIAG) guidelines. However, it’s also adopted in aerospace, medical, and industrial manufacturing for global supply chain quality.

- Why is Level 3 PPAP the industry standard?

Level 3 requires complete documentation and sample parts, making it the most trusted level for OEMs. Studies show 70%+ of global PPAP submissions are Level 3.

- How long does a PPAP submission take?

Depending on complexity, PPAP preparation can take 2–6 weeks. Digital PPAP tools reduce cycle times by 20% – 30%.

- What documents are mandatory in a PPAP package?

Standard PPAP documentation includes design records, DFMEA/PFMEA, control plan, dimensional reports, material tests, ISIR, capability studies, and PSW.

- What happens if PPAP is rejected?

A rejected PPAP means the supplier must correct issues, resubmit documentation, or adjust processes before production approval.

- How does PPAP differ from First Article Inspection (FAI)?

FAI validates the first part, while PPAP validates the entire production process for repeatability and compliance.

- Is PPAP required for service parts?

Yes. PPAP is often required for service and replacement parts, especially in automotive, to ensure consistency with original production.

Conclusion

Global supply chains now hinge on precision, consistency, and trust. It has turned PPAP into a compliance requirement that comes with a competitive advantage. Suppliers can demonstrate technical capability and commitment to excellence, risk reduction, and customer confidence.

Best Die Casting Services with the Most Reliable PPAP at HONJENNY

Honjenny has been a leader in the metal casting portfolio for three decades. We guarantee satisfaction through a well-organized PPAP for every order. Contact us to know more about our reliable services.