CNC precision machining lets manufacturers produce complex yet tolerant components with absolute consistency. It equips almost every tech to empower various industries that shape and run the world.

Digital design infused with an advanced cutting process to deliver extreme accuracy, repeatability, and speed. Explore vital insights into modern CNC precision machining within the manufacturing portfolio.

What Is CNC Precision Machining?

CNC means Computer Numerical Control. Meanwhile, CNC precision machining means using CNC systems to automate the shaping, cutting, and finishing of materials into highly detailed components.

CNC relies on digital instructions from CAD/CAM software to guide tools with exceptional accuracy. It’s mandatory for CNC parts to meet strict dimensional and finish standards to ensure the highest quality.

What is “Precision” Machining?

The ability to meet tight tolerance requirements remains at the forefront. You can induce tolerances down to ±0.001 mm, depending on the material and technique. For instance,

- Medical implants like orthopedic screws and dental components require sub-millimeter accuracy for biocompatibility.

- Aerospace turbine blades must maintain precise aerodynamic profiles to avoid catastrophic failure.

- Semiconductor components demand micron-level tolerances to ensure electrical performance and miniaturization.

Such a magnificent level of precision is possible through servo motors, feedback systems, and high-resolution encoders. They continuously monitor to make real-time adjustments to tool paths.

Consistency, Repeatability, and Surface Finish

CNC precision machining excels in repeatability. It denotes the ability to produce identical parts across thousands of cycles. The particular characteristic is crucial for –

- Mass production of auto parts, where uniformity affects safety and performance.

- Medical device manufacturing, where regulatory standards demand quality control.

CNC machines can achieve fine surface finishes (even below Ra 0.8 µm). Precision machining techniques like grinding, polishing, and high-speed milling reduce the need for post-processing.

How Does CNC Precision Machining Work?

CNC precision machining transforms digital designs into high-tolerance components. It features a four-step workflow – CAD modeling, CAM toolpath generation, machining execution, and final inspection.

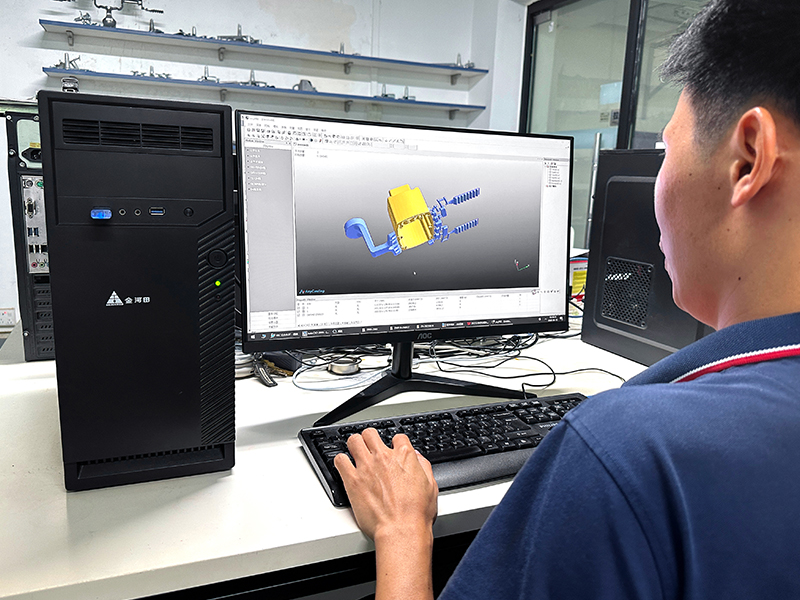

Step #01: CAD/CAM Modeling (CNC Programming)

The process begins with computer programs like Computer-Aided Design (CAD). Engineers create detailed 2D or 3D models of the desired part. The models define geometry, dimensions, tolerances, and surface features that serve as the blueprint for the manufacturing process.

- Common CAD formats include STEP (.stp), IGES (.igs), and SolidWorks (.sldprt).

- A well-optimized CAD model reduces machining time and minimizes errors.

- Siemens NX and Autodesk Fusion 360 are used in the aerospace and automotive sectors.

Step #02: Toolpath Generation

Computer-Aided Manufacturing (CAM) software converts the design into toolpaths. It’s a set of highly precise instructions that guide the CNC machine’s movements.

- G-code instructions, a language, tell the machine where to move, how fast, and what operations to perform.

- CAM software like Mastercam, HyperMill, or Fusion 360 CAM simulates machining to optimize cutting strategies and avoid collisions.

- Toolpath optimization can reduce cycle times by up to 30%. It’s particularly beneficial across high-volume production.

Step #03: Machining Execution

The CNC machine now takes over to execute the G-code instructions to shape the raw material. Whether it’s metal, plastic, or composite, the raw segment gets shaped into a final part.

- There are different machines like CNC mills, lathes, grinders, EDMs, and multi-axis centers.

- Machines perform operations like drilling, turning, milling, and electrical discharge cutting.

- Advanced systems like 5-axis CNC centers can machine complex features in a single setup.

Step #04: Inspection and Finishing

The part undergoes metrological inspection and surface finishing after the machining. It’s mandatory to meet the final specifications.

- Tools like Coordinate Measuring Machines (CMMs) and laser scanners verify dimensional accuracy.

- Surface finishing (grinding, polishing, anodizing, or bead blasting) enhances appearance, reduces friction, and improves corrosion resistance.

- Medical components are validated under ISO 13485 for biocompatibility and regulatory compliance.

Key Machining Operations in CNC Precision Manufacturing

CNC precision machining is more like a suite of several specialized operations. Each method revolves around specific geometries, various materials, and tolerances.

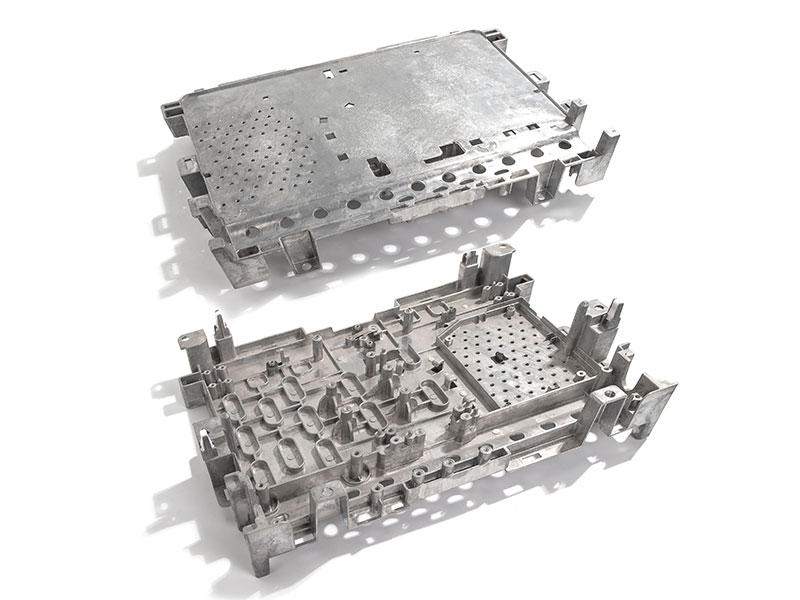

CNC Milling Machines: Multi-Axis Cutting for Complex Geometries

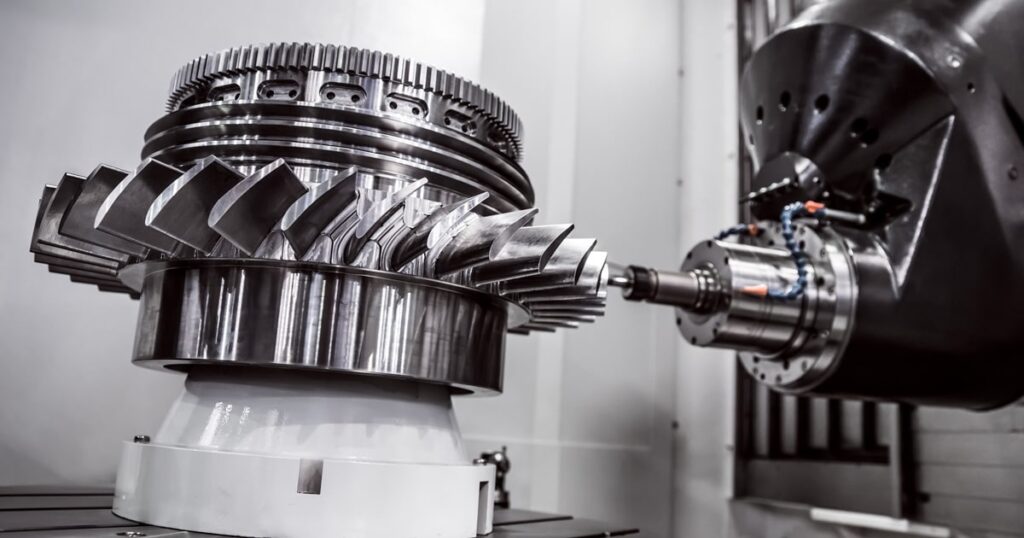

It uses rotating cutting tools for material removal from a stationary workpiece. Modern CNC mills operate on 3 to 5 axes to handle intricate shapes, undercuts, and cavities.

5-axis milling reduces setup time and improves precision by machining multiple faces in one go. It’s the perfect choice for engine blocks, turbine blades, and mold parts.

CNC Turning: Precision for Cylindrical Components

It involves rotating the workpiece while a stationary cutting tool removes material. The process mostly suffices for shafts, bushings, and threaded parts’ production.

CNC turning can achieve high concentricity and smooth finishes. It’s the common method in automotive drive shafts, aerospace fasteners, and medical implants.

CNC Grinding: Ultra-Fine Tolerances and Surface Quality

Grinding uses abrasive wheels to achieve excellent tolerances and surface finishes. The surface finish may count as low as Ra 0.2 µm in the measurement system.

Grinding is mandatory for hardened materials like tool steels and ceramics. It’s used in gear making, surgical instruments, and aerospace bearings.

EDM (Electrical Discharge Machining): Precision in Hard Metals

An electrode-workpiece combo incorporates electrical spark machining to remove material. Few alternatives are available for hard metals and intricate profiles.

No physical contact in the process means minimal mechanical stress. It’s particularly popular in die-making, aerospace turbine slots, and medical device molds.

CNC Drilling and Boring: Accurate Hole Placement

Drill bits create holes, while boring enlarges or refines them for precision fits. It’s used in engine blocks, circuit boards, and orthopedic implants. CNC systems ensure consistent depth, diameter, and spacing, critical for multi-part assemblies.

The global CNC machining market is projected to exceed $100 billion by 2030. Germany, Japan, and the US lead in CNC innovation. Companies like DMG Mori, Mazak, and Haas Automation have set the global benchmarks.

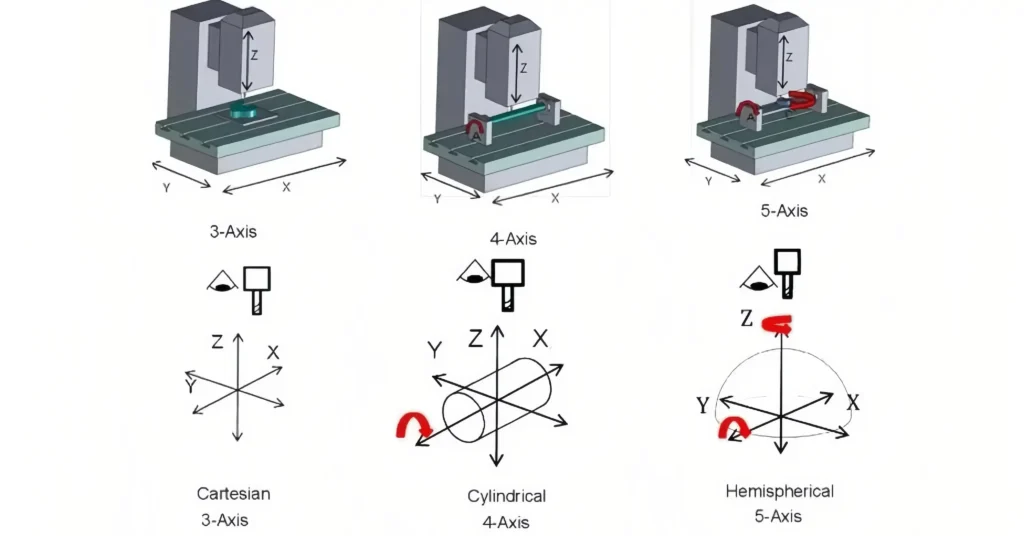

Different Types of CNC Machines: 3-Axis, 4-Axis, and 5-Axis Centers

Machining centers are defined by the number of axes along which the cutting tool or workpiece moves. More axes mean greater ability to produce complex geometries with fewer setups but higher precision.

3-Axis CNC Machines: Foundation of Precision Machining

The equipment operates along the X (left-right), Y (front-back), and Z (up-down) axes. Therefore, the cutting tool moves in three directions to shape the workpiece.

It’s the ideal option for flat surfaces, slots, holes, and basic contours. However, they can’t access undercuts or multi-angle features without repositioning the part.

4-Axis CNC Machines: Adding Rotational Flexibility

The CNC equipment includes all 3-axis movements plus a rotational axis (A-axis). It rotates the workpiece around the X-axis.

4-axis tools enable machining on multiple sides without manual repositioning. It’s useful for cylindrical parts, gears, and components with radial symmetry.

5-Axis CNC Machines: Mastering Complex Geometries

The equipment comes with two additional rotational axes. The machining tool rotates around A (rotation around X) and B (rotation around Y) to the standard 3 linear axes.

It’s capable of simultaneous multi-angle machining. Modern 5-axis machines can handle undercuts, compound curves, and intricate cavities in a single setup.

Summary Comparison

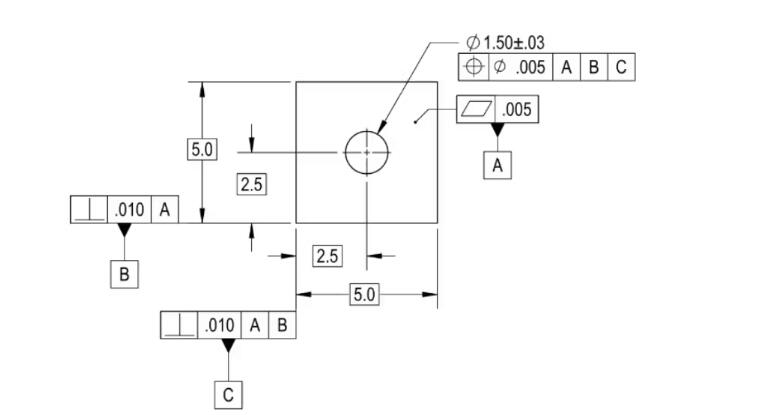

Relationship Between Precision and Tolerance in CNC Machining

Precision refers to the level at which a part conforms to its intended dimensions. It involves accuracy for a single part and repeatability across thousands of units. That’s where tolerance enters the picture.

Understanding Tolerance

Tolerance defines the permissible variation in a part’s dimensions. It’s the difference between the maximum and minimum acceptable limits. Even microscopic deviations can affect –

- Assembly fit (tight vs loose joints).

- Mechanical performance (vibration, wear).

- Safety and compliance (aerospace and medical sectors).

The tolerance range varies distinctly across different CNC machining services. For instance,

- Standard CNC Machining: ±0.05 mm tolerance for consumer electronics and general parts.

- High-Precision Machining: ±0.005 – 0.01 mm tolerance for automotive, robotics, and industrial tooling.

- Ultra-Precision Machining: ±0.001 mm tolerance for aerospace, optics, and medical implants.

Factors Influencing Precision

- Tool Stability: Worn or unstable tools introduce vibration and dimensional errors. Carbide tools and balanced tool holders help maintain precision.

- Material Type: Softer materials like aluminum are easier to machine precisely than hardened steels or composites. Such materials may deflect or wear tools faster.

- Temperature Control: Heat expansion can distort parts during machining. High-end CNC setups use coolant systems and thermal compensation algorithms.

Quality Assurance and Inspection

- Coordinate Measuring Machines (CMMs): Use probes to measure 3D dimensions with micron-level accuracy.

- Optical Comparators: Project magnified images of custom parts to compare against design profiles.

- Laser Scanners and Profilometers: Capture surface topography and detect deviations in finishes or contour.

Parts manufactured through CNC precision machining must meet international standards, including –

- ISO 2768: Defines general tolerances for linear and angular dimensions, simplifying drawings and reducing ambiguity.

- ASME Y14.5: Focuses on Geometric Dimensioning and Tolerancing (GD&T), specifying form, orientation, and location tolerances.

- GD&T: Engineers communicate complex tolerances clearly, reducing misinterpretation and improving manufacturability.

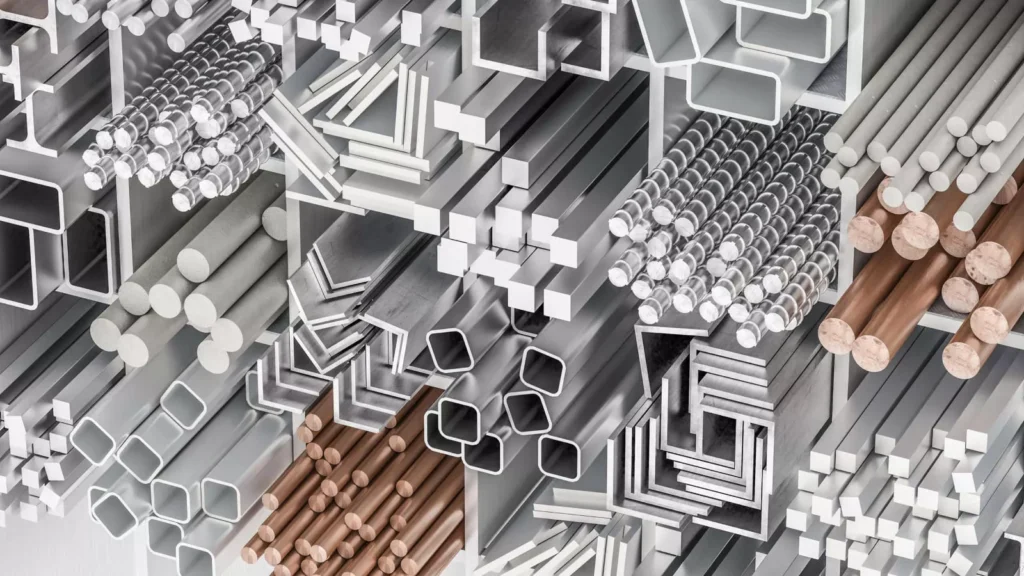

Common Metals in CNC Precision Machining

Material hardness and thermal properties directly affect different aspects. Softer materials allow faster machining; harder materials require slower speeds.

High-hardness or low-conductivity materials accelerate tool degradation. Coolants are essential for heat-sensitive materials to prevent warping or melting.

Metals in CNC Precision Machining

Metals are the backbone of CNC machining due to their strength, durability, and versatility. Commonly used metals are –

- Aluminum: Excellent machinability, low density, and high strength-to-weight ratio.

- Stainless Steel: Corrosion resistance, strength, and hygiene

- Brass and Copper: High electrical conductivity and smooth surface finishes.

- Titanium: Combines lightweight strength, corrosion resistance, and biocompatibility.

Plastics in CNC Precision Machining

Plastics offer flexibility, insulation, and chemical resistance. They seem better suited for prototyping and specialized applications.

- ABS (Acrylonitrile Butadiene Styrene): Lightweight, impact-resistant, and easy to machine.

- POM (Delrin): High stiffness and low friction.

- PEEK (Polyether Ether Ketone): High-performing, excellent heat resistance, and chemical stability.

- Nylon: Tough and wear-resistant, with good fatigue strength.

Advantages of CNC Precision Machining

- Unmatched Accuracy and Repeatability

CNC machining consistently delivers tight tolerances, often down to ±0.001 mm. The precision-machined parts meet exact specifications every time. It’s ideal for mass production and complex assemblies where dimensional consistency is critical.

- Design Flexibility

CNC systems support complex geometries, including internal cavities, compound curves, and multi-angle surfaces. It enables the production of parts that are impossible or inefficient to make with manual tools.

- Efficiency and Cost-Effectiveness

Automation in CNC machining reduces human error, material waste, and labor costs. Once programmed, machines can run unattended, even overnight. It takes short setup times for repeat projects – load the digital file and produce.

- Material Versatility

CNC machines can handle a wide range of materials with equal precision. Tool selection, spindle speed, and coolant systems are tailored to each material’s hardness and thermal properties for better results.

- Excellent Surface Finish and Post-Processing Compatibility

CNC machining achieves smooth surface finishes, often below Ra 0.8 µm. It minimizes the need for secondary operations. The precision CNC parts are well-compatible with anodizing, powder coating, polishing, bead blasting, and more.

- Scalable Control System

CNC machining is highly scalable, from single prototypes to high-volume production runs. Engineers can test the initial designs quickly, then transition to full-scale manufacturing without retooling.

Applications of CNC Precision Parts

- Aerospace

Titanium and aluminum alloys are commonly used for their strength-to-weight ratio. Components such as wing spars, fuselage frames, and jet engine rotors require tolerances as tight as ±0.001 mm.

- Automotive

CNC machining creates engine components (blocks, transmission housings, brackets, and heat sinks). CNC lathes and mills produce cylindrical shafts, pistons, and gear parts with high repeatability.

- Electronics

CNC machining is used to create die sinking, enclosures, and connectors with intricate geometries. CNC-milled RF connectors and antenna housings are used in 5G infrastructure and telecommunications.

- Medical/Healthcare

CNC machining produces surgical instruments, orthopedic implants, dental components, and diagnostic equipment. Materials like titanium, stainless steel, and PEEK are used for their biocompatibility.

- Industrial

CNC machining is used for turbine components, robotic arms, automation systems, and hydraulic parts. Such machined components must endure high pressure, temperature, and mechanical stress.

Challenges of High-Precision Machining

- Tool Wear and Calibration

Rapid tool wear has been one of the most persistent challenges in CNC machining. It directly affects dimensional accuracy, surface finish, and repeatability.

Regular calibration of CNC systems (spindle alignment, axis compensation, and probe accuracy) is mandatory to maintain tolerances as tight as ±0.001 mm.

- Material Waste

CNC machining is inherently subtractive, meaning material is removed from a solid block to create the final part. It leads to significant scrap, more in complex parts with deep cavities or intricate contours.

The process can produce up to 60% more waste than other methods, like 3D printing. CNC shops now choose nesting algorithms and optimized toolpaths to reduce waste and maximize material utilization.

- Complex Setup for Multi-Axis Machining

Advanced CNC systems like 5-axis machining require highly skilled programming and setup. Operators must manage tool orientation, collision avoidance, and fixture alignment across multiple axes.

Real-world execution demands a deep understanding of kinematics and part geometry. Errors in setup can lead to scrapped parts, machine crashes, or tool breakage, especially in aerospace or medical uses.

- Cost Balance

Precision CNC machining requires substantial capital investment in equipment, tooling, software, and skilled labor. A high-end 5-axis CNC machine can cost $250K – $500K without tooling and maintenance.

However, once operational, CNC offers competitive pricing with low per-part cost, minimal labor, and high throughput. ROI improves significantly with repeat production, tight tolerances, and low defects.

Future of CNC (Computer Numerical Control) Machining

- Integration of AI and IoT: Smart CNC Systems

The fusion of Artificial Intelligence (AI) and the Internet of Things (IoT) is central to Industry 4.0. It slowly but surely transforms CNC machining into a data-driven ecosystem.

- Hybrid Machining Centers: Additive Meets Subtractive

It combines additive manufacturing (3D printing) with conventional machining via CNC machinery. Manufacturers can build and finish parts in a single setup.

- Robotic Automation: 24/7 Production without Humans

Robotic arms and automated material handling systems are increasingly paired with precision CNC machining equipment. Robots handle loading/unloading, tool changes, and even inspection.

- Sustainability: Eco-Friendly Coolants and Recycling Systems

Environmental responsibility is becoming a priority in CNC machining. Vegetable-based coolants and minimum quantity lubrication (MQL) reduce hazardous waste and improve worker safety.

Frequently Asked Questions (FAQs)

- How does CNC machining compare to manual machining?

CNC machining offers superior accuracy, speed, and repeatability. It automates tool movements via digital instructions, reducing human error and increasing throughput.

- What is G-code in CNC machining?

G-code is the programming language that controls CNC machines. It dictates tool movements, speeds, and operations based on CAD/CAM inputs for the precise execution of part geometry.

- Can CNC machines produce prototypes and final products?

Yes. CNC machining is ideal for both rapid prototyping and full-scale production. Engineers can test designs quickly and scale up without retooling.

- How do CNC machines handle complex geometries?

Advanced CNC systems like 5-axis machines can rotate and tilt tools to access multiple angles. It allows the creation of undercuts, compound curves, and intricate cavities in one setup.

- What is the role of CAD/CAM software in CNC machining?

CAD software designs the part, while CAM software converts it into toolpaths and G-code. They enable the transition from digital model to physical component.

- Which materials are hardest to machine with CNC?

Titanium, hardened steels, and composites are challenging due to their toughness and low thermal conductivity. Precision requirements for a desired shape need specialized tooling and coolant systems.

- How does CNC machining support sustainability?

Modern CNC shops use recyclable materials, eco-friendly coolants, and chip reclamation systems to reduce waste and environmental impact.

- What certifications are important for CNC machining vendors?

Key certifications include ISO 9001 (quality management), AS9100 (aerospace), ISO 13485 (medical devices), and ITAR (defense compliance).

Conclusion

Complex systems can’t operate without intricate parts. And CNC precision machining enables steady and reliable production of such parts with high accuracy. And potential integration of AI, IoT, and hybrid machining is set to redefine what’s possible through smarter, faster, and more sustainable production.

Get the Topmost Machining Services at HONJENNY

Honjenny has been leading the metal manufacturing industry for 3 decades. Guaranteed satisfaction comes from an innovative solution for your needs. Contact us to know more about our current services.