Appropriate surface finishes go well beyond aesthetics in modern aluminum manufacturing. They directly participate in elevating the metal’s overall performance.

Relying solely on the protective oxide layer on the surface features potential risks in the long run. A well-engineered finish transforms raw aluminum into a resilient, functional, and aesthetic product.

This essential guide breaks down common aluminum finishes. Learn how each process works, what benefits they offer, and how to choose the best finish for your use.

Role of Surface Finishing in Aluminum Parts

Surface finishes refer to a set of mechanical, chemical, or electrochemical processes applied to metal surfaces. Their presence can modify physical, chemical, and aesthetic properties to a great extent.

- Improve Corrosion Resistance

Aluminum is naturally corrosion-resistant due to its oxide layer. Still, finishes like anodizing or powder coating dramatically extend such protection. For example, anodized aluminum can withstand salt spray for over 1,000 hours.

- Enhance Aesthetic Appeal

Surface finishes let aluminum components mimic textures like brushed steel, glossy chrome, or matte black. Such flexibility is obligatory in consumer products. Apple’s MacBook line uses anodized finishes for scratch-resistant surfaces for color integrity.

- Increase Wear Resistance

Hard anodizing can significantly increase the surface hardness up to 60 Rockwell C. Such robustness makes the metal comparable to hardened steel. It’s crucial in aerospace and industrial tooling to reduce friction + abrasion.

- Support Adhesion of Paints or Coatings

Pre-treatments like chromate conversion or etching improve paint adhesion. They also ensure coatings don’t peel or flake. It’s especially important for automotive manufacturers, where multi-layer paint relies on strong base adhesion.

Aluminum Oxide Layer: The Natural Finish

Aluminum forms a thin oxide film (2 to 3 nanometers thick) upon its exposure to air. The passive layer enables corrosion resistance by preventing further oxidation. However, it has specific limitations.

- Thin and Inconsistent: The oxide layer varies in thickness and uniformity depending on environmental exposure. It may degrade rather quickly in humid or coastal uses, leading to pitting or discoloration.

- Limited Mechanical Protection: It doesn’t offer sufficient resistance to wear, impact, or chemical attack. For example, untreated aluminum across industrial settings can scratch or corrode within weeks.

- Poor Adhesion for Coatings: Paints and adhesives fail to bond effectively to untreated aluminum. It’s quite problematic when applied poorly. Such cases deal with peeling/bubbling under stress or heat.

Different Types of Aluminum Finishes

Practiced surface finishing for aluminum primarily falls into three main categories. Each type marks distinct advantages based on performance, aesthetics, and cost.

- Mechanical Finishes

They physically alter the surface of aluminum to achieve a desired texture, gloss level, or pattern. Such processes mostly mark the very first step before applying further treatments. Common methods –

- Brushing: Uniform texture with a linear grain.

- Polishing: Enhanced reflectivity for a mirror-like finish.

- Bead Blasting or Sandblasting: Matte + non-reflective surface.

- Grinding or Buffing: Removal of imperfections to prepare for coating or anodizing.

- Chemical and Electrochemical Finishes

Such finishes rely on chemical reactions or electrical currents to modify the surface at a molecular level. The finishing can improve corrosion resistance, various colors, and surface hardness. Key processes –

- Anodizing: An electrochemical process to thicken the oxide layer. It can increase hardness and corrosion resistance.

- Alodine (Chromate Conversion Coating): A chemical method to enhance corrosion resistance and paint adhesion.

- Etching or Bright Dipping: Chemical baths for aluminum that clean or brighten the surface before further finishing.

- Organic and Inorganic Coatings

The finishing comes from applying external layers to the surface. It can be organic (carbon-based) or inorganic (mineral-based) to protect and enhance the aluminum’s appearance. Popular choice includes –

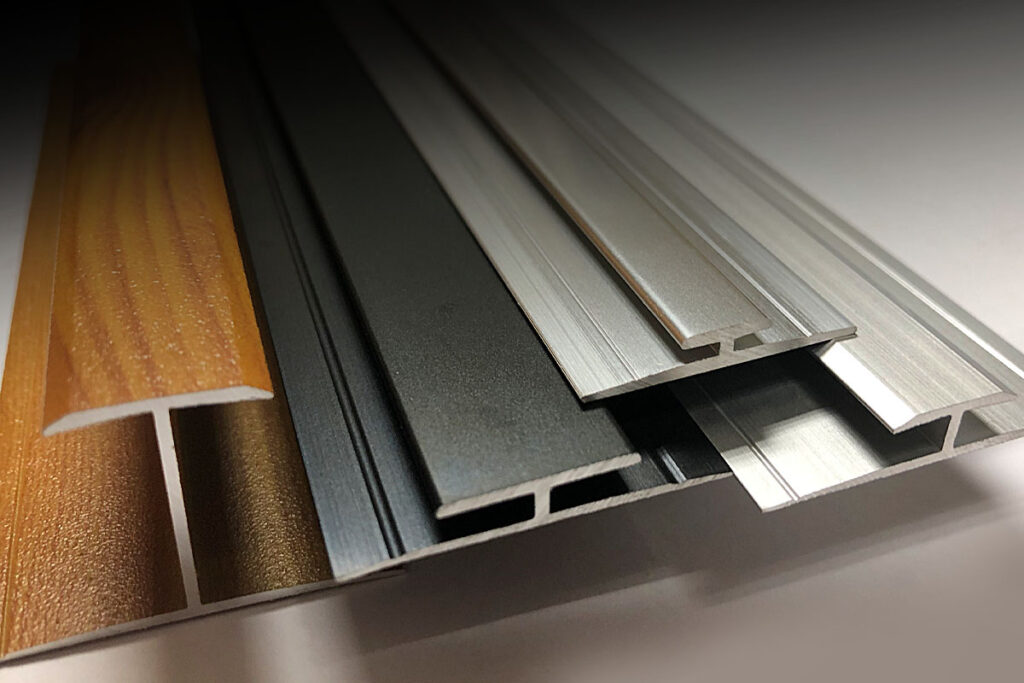

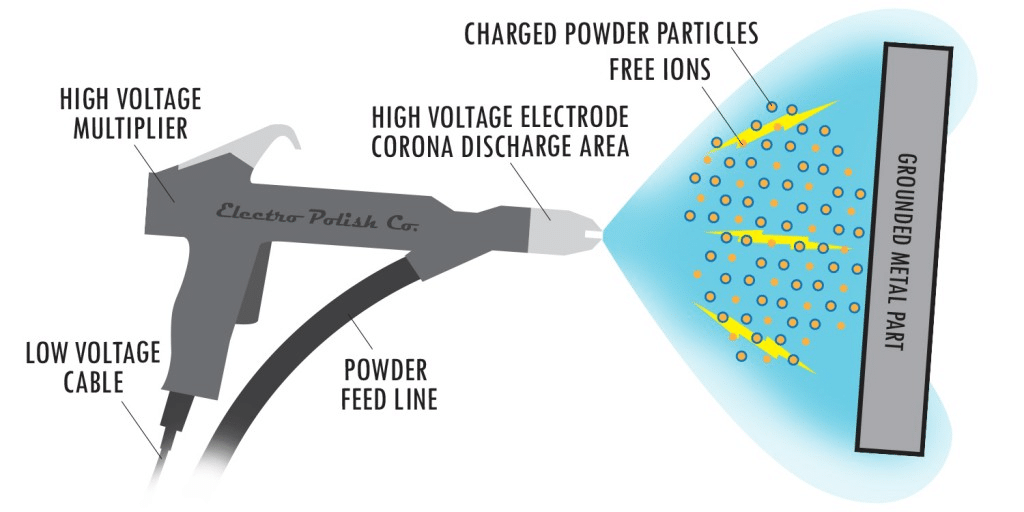

- Powder Coating: A dry powder is electrostatically applied and cured under heat. It offers excellent durability, UV resistance, and color variety.

- Liquid Paints: They’re preferred for complex shapes or when specific gloss levels are needed. The paint gets layered with primers and topcoats.

- Ceramic or Enamel Coatings: They present inorganic options with extreme heat and chemical resistance. The coats suit cookware and industrial uses.

Aluminum Surface Finish: Mechanical Approaches

- Polishing

The process implements abrasive compounds and rotary tools to create a smooth + reflective surface. It can range from satin to mirror-like finishes, depending on the grit and polishing method.

Real-Time Application: High-end consumer electronics, automotive trims, and architectural designs. Polished aluminum is heavily used in luxury car interiors across Europe in brands like BMW and Audi.

- Brushing

The method creates a consistent + linear grain pattern by dragging abrasive belts or pads across the surface. It reduces glare while adding a modern and practical aesthetic.

Application Case: Kitchen appliances, signage, and decorative panels. Brushed aluminum is a signature finish in Apple’s MacBook line that offers elegance and fingerprint resistance.

- Buffing

Buffing smoothens minor imperfections and prepares aluminum for subsequent treatments. It relies on soft cloth wheels and fine abrasive media to refine the surface without removing much.

Real-World Applications: Pre-treatment before anodizing or painting. Buffing is common in aerospace and medical devices, where surface uniformity is mandatory.

- Shot Blasting / Bead Blasting

Such approaches incorporate high-pressure streams of media (steel shot or glass beads) to craft a matte + non-reflective surface. They’re good at removing contaminants and creating uniform textures.

Application Case: Industrial components, outdoor fixtures, and automotive parts. Bead blasting prepares aluminum molds for high-tolerance plastic injection across Japan’s precision tooling industry.

Standard Benefits of Mechanical Finishes

- Improved Surface Uniformity: Removed scratches, tool marks, and inconsistencies.

- Enhanced Aesthetics: Available in distinctive textures, ranging from glossy to matte.

- Better Adhesion: Well-prepared surface to bond with coatings, paints, or anodizing.

- Cost-Effective: Usually less expensive than chemical or electrochemical treatments.

- Eco-Friendly: Zero involvement of harsh chemicals reduces environmental impact.

Some Downsides to Consider

- Limited Corrosion Protection: Minimal improvement in resistance unless paired with coatings.

- Surface Damage Risk: Over-polishing/aggressive blasting can weaken thin aluminum sections.

- Labor-Intensive: Some mechanical techniques require skilled operators and manual effort.

- Inconsistent Results: Finishing may vary significantly between batches without automation.

Aluminum Finish: Chemical and Electrochemical Finishes

- Anodizing

The electrochemical conversion thickens the aluminum’s natural oxide layer. Aluminum acts as the anode in an acid electrolyte bath (commonly sulfuric acid). An electric current is passed through the acid. It forms a controlled and porous layer that can be sealed/dyed. Common variants –

- Type I: Chromic acid anodizing creates a thin layer.

- Type II: Sulfuric acid anodizing (standard) induces a protective layer.

- Type III: Hard anodizing creates a thick and wear-resistant layer.

Anodizing Benefits

- Excellent corrosion resistance.

- Increased surface hardness (up to 60 Rockwell C).

- Dyeable for aesthetic customization.

- Environmentally stable and UV resistant.

Potential Limitations

- A brittle oxide layer may crack under stress.

- Requires precise process control.

- Not ideal for complex geometries due to uneven coating.

General Applications

- Consumer Electronics: Apple’s MacBook uses Type II anodizing for sleek finishes.

- Architecture: Curtain walls and window frames in high-rise buildings.

- Aerospace: Hard-anodized components for wear resistance and weight savings.

- Chemical Conversion Coating (Chromate or Non-Chromate)

It involves immersing aluminum in a solution (mostly chromate-based) that forms a protective film. The film can effectively improve corrosion resistance and paint adhesion. Non-chromate alternatives are in high demand due to environmental regulations.

Conversion Coating Benefits

- Enhances corrosion resistance.

- Excellent base for paints and adhesives.

- Low-cost and fast application.

- It can be applied at room temperature.

Potential Limitations

- Hexavalent chromium is a carcinogen.

- Non-chromate alternatives offer reduced performance.

- Somewhat limited resistance to wear.

General Applications

- Aerospace: The coating provides a durable finish for aircraft skins and fasteners.

- Military: MIL-DTL-5541 standards govern chromate coatings for defense equipment.

- Electronics: Enclosures and connectors to prevent corrosion with high electrical conductivity.

- Electroplating

The process deposits a thin layer of metal (nickel, copper, gold) onto aluminum using an electric current. Since aluminum is non-conductive in its native state, it needs a zincate pre-treatment to enable plating. Several variants are available –

- Nickel Plating: For wear and corrosion resistance.

- Copper Plating: For electrical conductivity.

- Gold Plating: For high-end electronics and connectors.

- Electroless Plating: Chemical reduction instead of electricity for complex shapes.

Electroplating Benefits

- Enhanced conductivity and solderability.

- Improved corrosion and wear resistance.

- Superior decorative appeal.

- Multi-metal layering for advanced functionality.

Potential Limitations

- Requires multiple steps and precise control.

- Adhesion issues occur when pre-treatment is inadequate.

- Environmental concerns due to heavy metals and chemical waste.

General Applications

- Electronics: Gold-plated connectors in smartphones and servers.

- Automotive: Nickel-plated trim and engine components.

- Medical Devices: Electroless nickel plating for biocompatibility and sterilization resistance.

Organic and Inorganic Aluminum Coating

- Powder Coating

It indicates the electrostatic application of dry powder resin onto aluminum surfaces. The coated part is cured in an oven after the application. The powder melts and forms a smooth + uniform film. The process eliminates the need for solvents and produces a thick + protective layer.

Notable Advantages

- Uniform Coverage: Coating thickness remains 50 – 120 μm, which enables robust protection.

- Excellent Resistance: Highly resistant to UV, corrosion, and impact for exterior applications.

- Color and Texture Variety: Gloss, satin, textured, and matte finishes with many color options.

- Environmentally-Friendly: No volatile organic compounds (VOCs), low environmental impact.

General Applications

- Consumer Goods: Kitchen appliances, electronics casings.

- Outdoor Furniture: Patio sets, railings, and garden fixtures.

- Automotive Trims: Wheel rims, bumpers, and roof rails.

- Liquid Painting

The traditional wet coating involves spraying aluminum with paint containing solvents, pigments, and binders. It involves multiple layers (primer, basecoat, and topcoat) for optimal adhesion and finish.

Painting Benefits

- Low setup cost: Ideal for small-scale or custom production.

- Simple application: Can be applied manually or with automated sprayers.

- Color versatility: Easier to match specific shades or gradients.

Potential Limitations

- Thinner coating: Typically 15 – 25 μm, offering less protection than powder coating.

- VOC emissions: Solvent-based paints release VOCs, requiring ventilation and environmental controls.

- Durability: Less resistant to abrasion and weathering compared to powder coating.

General Applications

- Appliances: Refrigerators, ovens, and washing machines.

- Signage and Displays: Custom graphics and branding.

- Automotive: Touch-up and specialty finishes.

- Ceramic and PVD Coatings

Ceramic coatings and Physical Vapor Deposition (PVD) involve high-tech processes to deposit ultra-thin but hard layers on aluminum. PVD relies on vaporized metal particles in a vacuum chamber to create a metallic or ceramic finish.

Noteworthy Advantages

- Exceptional hardness: PVD coatings can reach 2000 HV on the Vickers scale.

- Scratch and wear resistance: Ideal for high-contact or precision components.

- Decorative appeal: Offers metallic tones like gold, titanium, and graphite with a premium look.

- Chemical stability: Resistant to acids, solvents, and high temperatures.

General Applications

- Electronics: Smartphone frames, camera housings.

- Tools: Drill bits, cutting tools, and surgical instruments.

- Luxury Hardware: Faucets, door handles, and watch cases.

Protective Coating Options and Treatments

Surface finish, even the best one, may require backups to withstand extreme or long-term harshness. Always consider maximizing aluminum’s longevity, performance, and visual appeal as much as possible.

- Clear Coating / Sealing: Locking in the Finish

It primarily marks the final step after anodizing or other surface treatments. Sealing or coating involves applying a transparent layer (organic [polyurethane or acrylic] or inorganic [silicate-based sealants]).

It actively prevents oxidation and environmental degradation. More specifically, the porous oxide layer gets sealed, which prevents moisture and contaminants from penetrating. The topmost benefits are –

- Preserves color and gloss.

- Enhances corrosion resistance.

- Reduces fingerprinting and staining.

- E-Coating (Electrophoretic Coating): Uniform Coverage for Complex Shapes

E-coating or electrophoretic deposition refers to a wet finishing process. Electrically charged paint particles get deposited on aluminum surfaces within a bath.

It ensures equal coverage throughout the part with a thin film (20 – 25 μm), even with intricate geometries. Involved steps would be –

- Aluminum is pretreated (cleaned and etched).

- The part is immersed in a bath containing paint particles.

- An electric current causes the particles to migrate and adhere uniformly.

- Aluminum alloys are then baked to cure the durable coating.

Applications: Automotive components, electronics enclosures, and industrial machinery.

- Hard Coat Anodizing + Sealing: Maximum Wear and Color Protection

Hard coat anodizing also goes by Type III anodizing. It produces a thick and dense oxide layer (up to 100 μm) to confront wear-prone/corrosive substances. The coated anodizing delivers mechanical strength and aesthetic longevity when paired with sealing.

Notable Benefits

- Surface hardness up to 60 Rockwell C.

- Extreme abrasion and chemical resistance.

- Retained color and gloss under UV exposure.

- Ideal for military, aerospace, and industrial tools.

Potential Limitations

- Higher cost and energy consumption.

- Darkened aluminum limits color options.

Importance of Pre-Treatment for Aluminum Products

Before applying any coating, surface preparation is mandatory. Poor adhesion can lead to peeling, bubbling, and premature failure.

- Degreasing: Removal of oils, lubricants, and contaminants from machining or handling.

- Etching: Acid or alkaline solutions to roughen the surface, improving mechanical bonding.

- Desmutting: Elimination of residues left after etching, especially on high-silicon alloys.

Why Proper Pre-Treatment is So Important?

- To ensure uniform coating thickness.

- To enhance corrosion resistance.

- To reduce rework and quality failures.

Summary Comparison: Different Aluminum Finishes

How to Choose the Right Aluminum Finish?

The perfect finish is all about balancing performance, aesthetics, and production realities. An ideal finish should enhance durability, meet design specifications, fit the budget, and fulfill sustainability targets.

- Corrosion Resistance

Your aluminum product may face moisture, salt spray, or chemicals more frequently. In such a case, corrosion resistance becomes mandatory.

Anodizing creates a thick oxide that resists corrosion in marine and architectural environments. Powder coating offers excellent protection in coastal regions, withstanding salt spray for over 1,000 hours.

Chromate conversion coatings are widely used in aerospace for corrosion protection and paint adhesion. Anodized aluminum panels also withstand sand abrasion and UV exposure.

- Durability and Wear Resistance

Some parts are subject to frequent handling, abrasion, or mechanical stress. Therefore, finishes must offer surface hardness and wear resistance.

Hard coat anodizing (Type III) increases surface hardness up to 60 Rockwell C. PVD coatings are used in tools and electronics for extreme scratch resistance.

Electroplating with nickel or chrome adds both wear resistance and conductivity. Over 80% of aluminum in aerospace and defense is hard anodized or conversion coated.

- Aesthetic and Design Factors

Various industries like consumer electronics and architecture demand aluminum finish options that reflect brand identity. Anodizing allows for metallic tones and matte or glossy textures.

Powder coating offers thousands of color and texture combinations, from smooth gloss to rough matte. Brushing and polishing create tactile finishes that reduce glare or enhance reflectivity.

- Production and Cost Considerations

Powder coating is ideal for high-volume + continuous production due to its automation and low per-unit cost. Liquid painting suits low-volume or custom batches thanks to its lower setup cost + flexibility.

Mechanical finishes like brushing or polishing are labor-intensive and better suited for small to medium runs. Anodizing and electroplating require specialized tanks + electrical setups, increasing lead time.

- Sustainability and Recyclability

Powder coating is eco-friendly, emitting nearly zero VOCs while allowing overspray recovery. Non-chromate conversion coatings continue to gain popularity in Europe due to REACH regulations.

Anodized aluminum remains fully recyclable without compromising its protective layer. Tesla’s Gigafactory uses powder-coated aluminum battery casings for resistance with sustainability.

Frequently Asked Questions (FAQs)

- What is the difference between mill finish and anodized aluminum?

Mill finish is untreated aluminum with a raw + dull appearance and minimal corrosion resistance. Anodized aluminum offers improved durability, color options, and weather resistance.

- Can aluminum finishes affect thermal conductivity?

Yes. Coatings, like anodizing or powder coating, slightly reduce thermal conductivity. Bare or polished aluminum retains higher thermal efficiency, preferable for heat sinks and electronics.

- Are aluminum finishes safe for food-contact surfaces?

Yes, but only specific finishes. Hard anodizing and FDA-approved powder coatings are safe for cookware and food equipment. Always avoid finishes with chromates or non-food-grade paints.

- How do aluminum finishes impact electrical conductivity?

Bare or electroplated aluminum (with copper or silver) can maintain conductivity. Anodized or coated aluminum harnesses electrical insulation properties unless selectively masked or treated.

- Can aluminum be finished to look like stainless steel or brass?

Yes. Brushed finishes mimic stainless steel. Meanwhile, anodizing or PVD coatings can replicate brass, bronze, or gold tones. These are common in architectural and decorative applications.

- Do aluminum finishes affect recyclability?

Most finishes, including anodizing and powder coating, don’t prevent aluminum from being recycled. However, finishes must be removed/separated during recycling to maintain purity.

Conclusion

Lightweight aluminum can’t deliver its promised performance, innovation, and protection without a surface finish. The finish you choose defines how your aluminum products endure and inspire. There are different finishes, with each finish unlocking unique characteristics to suit specific applications.

Perfect Aluminum with the Best Finish for Intended Application at HONJENNY

Honjenny has been leading the aluminum manufacturing industry for about 30 years. Our experts know what you need based on project specifications. Contact us to know further about our finishing services.