Metal casting has remained a crucial manufacturing method for thousands of years. It transforms molten metal into innovative, precise, and functional shapes for everyday applications.

Particular methods like investment casting are available with the advancement of technology. Still, die casting and sand casting have been two of the most dominant methods for centuries.

Both techniques are deployed across industries by leveraging the significant benefit of casting. This article dives deep into the core differences between die casting and sand casting.

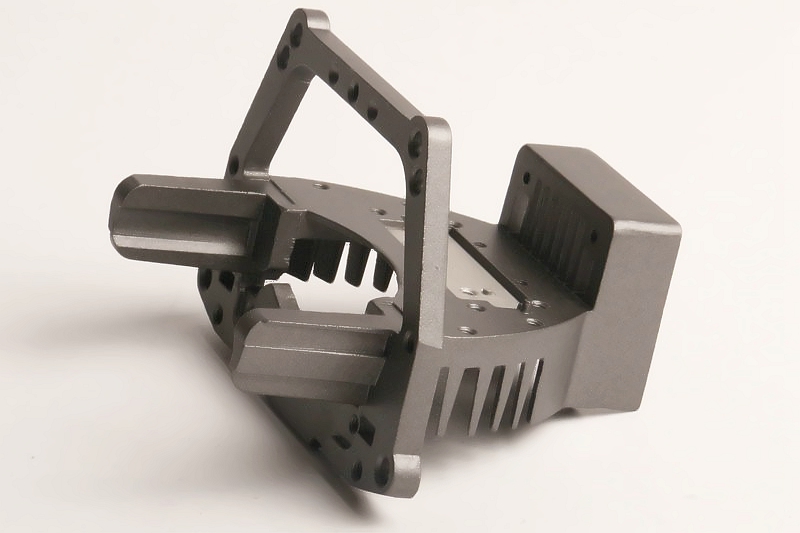

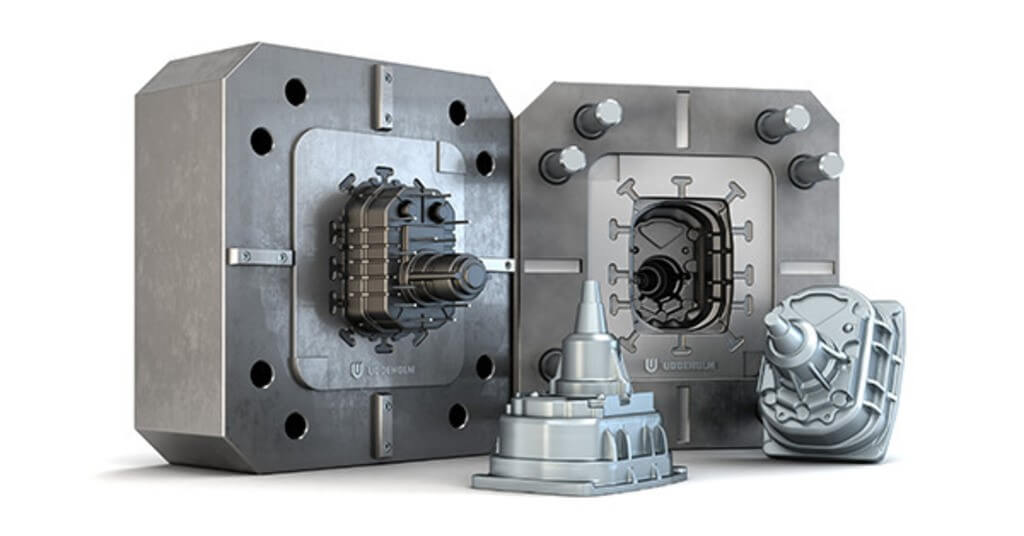

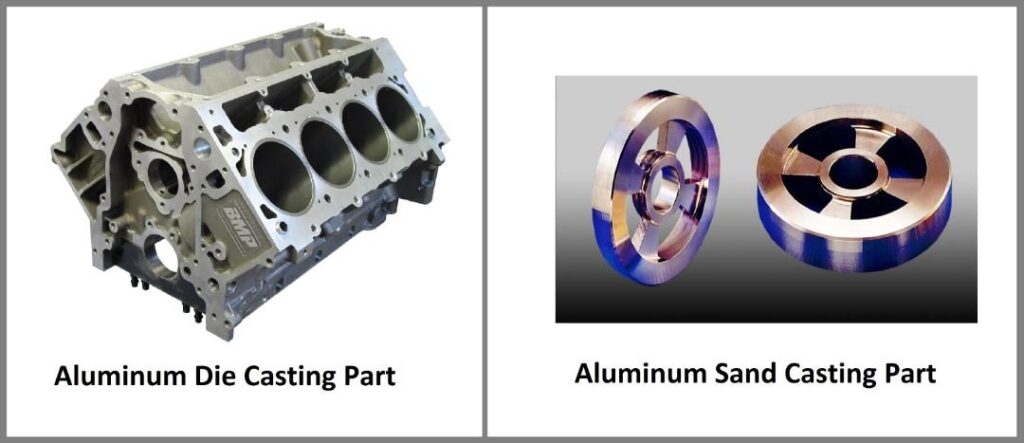

What Is Die Casting?

It’s a high-pressure metal casting process to create precisely metal components. The process primarily involves alloys of aluminum, zinc, or magnesium.

Die Casting: Step-by-Step

- Mold Design and Creation: Engineers design steel molds according to the desired shape in fine detail. The dies are precision-machined to withstand repeated high-pressure cycles.

- Metal Melting: The chosen metal alloy is melted based on its melting point in a furnace. For instance, aluminum melting point helps reach the optimal casting temperature.

- Injection Under High Pressure: Molten aluminum gets injected into the die cavity at immense pressure (1500 to 25000+ psi). Such pressure ensures complete filling and minimal porosity.

- Cooling and Solidification: The pressed metal cools rapidly within the die to solidify and create the final part. However, the cooling time depends on part thickness and alloy type.

- Ejection and Trimming: Upon complete solidification, the part gets ejected from the die. Excess material (like flash or sprues) is trimmed off to produce a clean and finished product.

Different Types of Die Casting

The die casting process isn’t exactly one-size-fits-all. Manufacturers choose from several subtypes based on material, part complexity, and production goals.

- High-Pressure Die Casting (HPDC): The most common method, where extreme pressure injects metal into the die. HPDC is suitable for thin-walled and complex shapes on high-volume production runs.

- Low-Pressure Die Casting (LPDC): It relies on lower pressure to fill the mold from below, reducing turbulence. LPDC seems suitable for larger parts with better mechanical strength.

- Vacuum Die Casting: A vacuum removes air from the mold cavity before injection to reduce porosity. The cast parts are mostly structural components that require superior mechanical integrity.

Characteristics of Die Casting

- Dimensional Accuracy: Tolerances as tight as ±0.1 mm are achievable. It reduces the need for post-machining.

- Surface Finish: Smooth surfaces (Ra 1.6 – 3.2 µm) prevail for decorative or functional coatings.

- High-Speed Production: Cycle times can be as short as 30 seconds, creating hundreds of parts per hour.

- Complex Geometries: Intricate designs, including thin walls (as low as 0.5 mm) and integrated features, are achievable.

- Material Efficiency: Minimal waste generation due to near-net-shape forming with die casting molds and recyclable scrap.

- Metal-Based Casting: Aluminum (Al) die casting, Zinc (Zn) die casting, and magnesium (Mg) die casting with alloys.

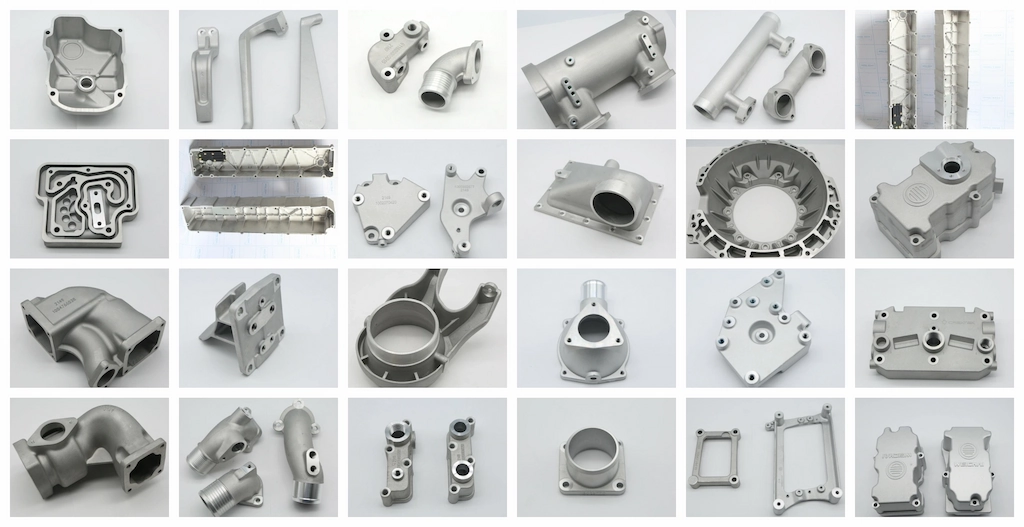

Real-Time Applications

- Automobile: Over 60% of aluminum die castings globally are used in automotive parts like transmission housings, engine blocks, and brackets.

- Electronics: Magnesium die casting is popular for smartphone frames and laptop casings due to its lightweight and EMI shielding properties.

- Aerospace: Vacuum die casting has been significantly featured in turbine blades and structural supports where porosity-free parts are critical.

The global die casting market is projected to exceed $121 billion by 2030. Such demand has been driven by the increasing popularity of light, exact, and functional parts in EVs and renewable energy.

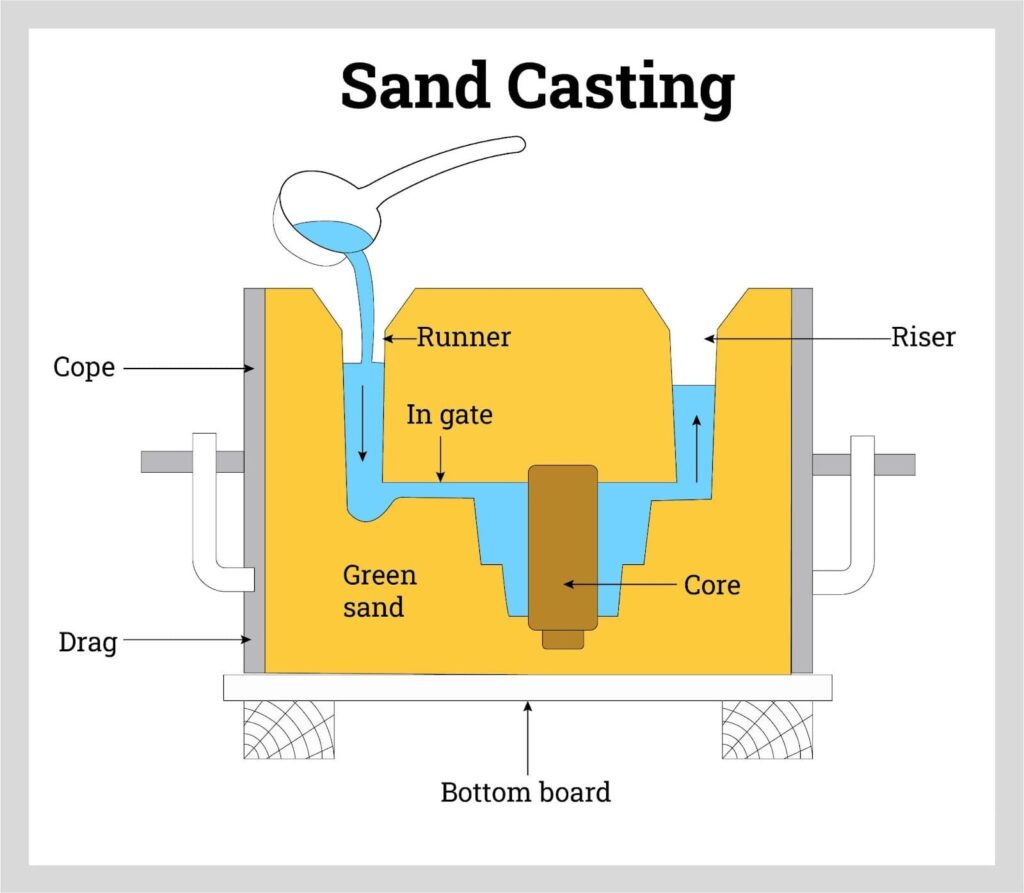

What Is Sand Casting?

It’s one of the oldest metal casting methods, dating back nearly 5,000 years to ancient Egypt. Molten metal is poured into a sand mold, which is broken apart after the metal solidifies.

Sand Casting Process: Step-by-Step

- Pattern Creation: A replica of the final product is made using wood, plastic, or metal. This pattern defines the cavity shape and is used to form the sand mold.

- Sand Mold Formation: The pattern is placed in a molding box with packed sand mixed with a binder (like clay or resin). If the part has internal cavities, cores are added to shape them.

- Molten Metal Pouring: Once the mold becomes ready for use, molten metal gets poured into the cavity through gravity or pressure.

- Cooling and Solidification: The metal cools and solidifies inside the mold. Likewise, the cooling time varies based on part size and material.

- Mold Breaking and Part Cleaning: After solidification, the sand mold is broken apart to retrieve the casting. The part is then cleaned, and excess material is removed.

Characteristics of Sand Casting

- Low Tooling Cost: Tooling expenses are 5% – 10% of die casting costs in small production runs and rapid prototyping.

- Large and Heavy Components: Sand casting can produce parts weighing over 100 tons, such as locomotive frames, engine blocks, and industrial pumps.

- Wide Material Compatibility: The process works with ferrous and non-ferrous metals, including steel, iron, and bronze.

- Design Flexibility: There are no strict size or shape limitations with sand casting. Engineers can easily modify designs without expensive retooling.

Real-Time Applications

- Automotive: Cylinder heads, engine blocks, and brake components.

- Machinery: Gear housings, pump casings, and agricultural equipment.

- Aerospace: Prototype turbine components and structural supports.

- Art + Architecture: Bronze sculptures, decorative panels, and heritage restorations.

Sand casting accounts for about 60% – 70% of all metal castings produced worldwide. Not to mention, it’s the most widely used casting method.

Die Casting vs Sand Casting: Key Differences

The best casting method significantly impacts the cost, quality, and efficiency of the manufacturing. Each method has distinct advantages depending on the application, material, and production goals.

- Mold Type

Die casting uses permanent steel molds (dies) that can withstand high pressure and repeated use. The molds are precision-machined and ideal for high-volume production.

Sand casting depends on expendable sand molds formed around a pattern. Each mold gets completely destroyed after the intended use, allowing flexible design changes.

- Production Volume

Die casting is the best manufacturing process for high-volume production due to fast turnaround and reusable molds. Meanwhile, sand casting is ideal for low to medium-volume production, rapid prototyping, or customized parts.

- Geometric Precision

Die casting offers tight tolerances (±0.1 mm) and high dimensional accuracy for metal parts. However, sand casting is less precise with tolerances around ±0.5 mm or more, depending on mold quality.

- Part Size

Die casting is suitable for small to medium-sized parts due to mold and machine limitations. Sand casting can handle very large components, including parts weighing over 100 tons.

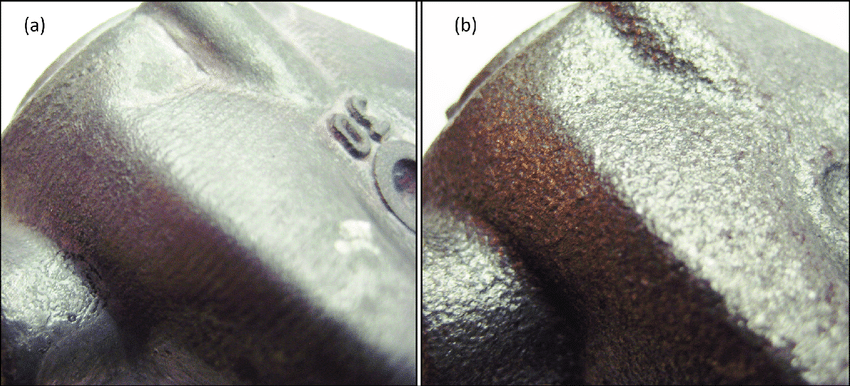

- Surface Finish

Die casting produces an excellent finish for surfaces (Ra 1.6–3.2 µm). The end products require minimal post-processing. Sand casting results in rougher surfaces due to sand texture. Therefore, the crafted parts often need machining or polishing.

- Tooling Cost

The die casting process requires a high initial tooling cost due to complex die design and machining. Sand casting comes with low tooling costs. Standard or available patterns are inexpensive; even the molds are made from reusable sand.

- Cycle Time

As mentioned, die casting enables fast cycle times of 30 seconds to 2 minutes per part. Sand casting is time-consuming, which may require minutes to hours, depending on the size and cooling. Die casting creates hundreds of parts per hour, ideal for consumer electronics and automotive parts.

- Part Durability

Die casting produces parts with high strength-to-weight ratios. It’s particularly true with vacuum or low-pressure variants. Sand casting offers robust mechanical properties for thick-walled or high-load parts.

- Design Consideration

Die casting requires precise mold design. Changing the design is troublesome once the tooling is made. Sand casting grants more flexibility, allowing easy modifications to patterns and mold geometry.

- Common Metals

Die casting primarily deals with non-ferrous metals like aluminum, zinc, and magnesium. Aluminum die casting dominates in EV battery housings.

Meanwhile, sand casting remains compatible with ferrous and non-ferrous metals. Steel, iron, bronze, and even aluminum. Iron sand casting leads the heavy machinery industry.

Summary Comparison: Sand Casting vs Die Casting

Choosing the Right Casting for Your Next Project

Selecting between die casting and sand casting affects cost, quality, scalability, and product performance. You may design a lightweight auto part or a massive industrial pump housing. Understanding the nuances of each method becomes essential to obtain optimal results.

- Production Volume

Die casting is ideal for high-volume production. Its fast cycle and reusable molds are cost-effective when producing too many parts.

Sand casting suits low to medium-volume runs, prototypes, and custom parts. Its low tooling cost allows for flexibility without a large upfront investment.

Die casting becomes economically viable when producing over 1,000 units. Meanwhile, sand casting is preferred for under 500 units.

- Part Complexity and Precision

Die casting can create complex geometries, thin walls, and tight tolerances (±0.1 mm). Sand casting handles simpler or larger designs with moderate precision (±0.5 mm or more).

Still, you can enjoy a rather straightforward flexibility in design. Smartphone frames and EV battery enclosures are die cast, whereas large housings and engine blocks are sand cast.

- Material Selection

Die casting is limited to non-ferrous metals like aluminum, zinc, and magnesium. Sand casting supports a wider range, including ferrous metals like steel and iron, as well as bronze and aluminum.

Sand casting remains dominant for iron and steel components in infrastructure and machinery across China and India. Die casting leads in auto parts and electronics in Europe and North America.

- Tooling and Setup Cost

Die casting requires expensive dies and setup, ranging from $20,000 to $100,000+. Sand Casting uses inexpensive patterns and sand molds, costing under $1,000.

Startups or R&D teams should begin with sand casting as it offers a low-risk entry point for testing designs. Committing to die casting later should yield better outcomes.

- Part Size and Weight

Die casting is limited to small to medium-sized parts due to machine constraints. Sand casting can produce massive components, including parts weighing over 100 tons.

- Surface Finish and Post-Processing

Die casting delivers smooth surfaces without many finishing processes (direct painting or plating). Sand casting mostly requires machining or polishing due to rough surfaces.

Manufacturers can skip secondary surface finishing with immediately ready die-cast parts. It saves them time and cost in consumer electronics and appliance manufacturing.

Frequently Asked Questions (FAQs)

- Which casting method is better for rapid prototyping?

Sand casting is preferred for prototyping due to its low tooling cost and quick mold turnaround. Die casting requires expensive dies and a longer setup time.

- Can die casting and sand casting be automated?

Die casting has become highly automated in modern foundries, especially for high-volume production. Sand casting can be semi-automated, but manual labor is still common.

- Which process offers better repeatability – die casting or sand casting?

Die casting provides excellent repeatability due to permanent molds and controlled injection systems. Sand casting has more variability due to manual mold creation and sand inconsistencies.

- Which method is better for structural integrity?

Sand casting is better for structural parts due to thicker walls with cast iron/steel. Die casting is suitable for lightweight structural components that may require post-treatment for strength.

- How do cooling rates differ between die casting and sand casting?

Die casting initiates rapid cooling due to metal molds, resulting in a finer grain structure. Sand casting with a slower cooling leads to coarser grains and different mechanical properties.

Conclusion

Die casting shines with unmatched precision, speed, and finish for intricate designs. Sand casting offers flexibility, scalability, and material versatility to meet evolving design needs. However, your ultimate method depends on production, complexity, and budget.

Receive the Best Die Casting Services at HONJENNY

Honjenny has been an industry leader in the metal casting portfolio. We’re ready to meet your specs through innovation, commitment, and precision. Contact us to know more about our casting services.