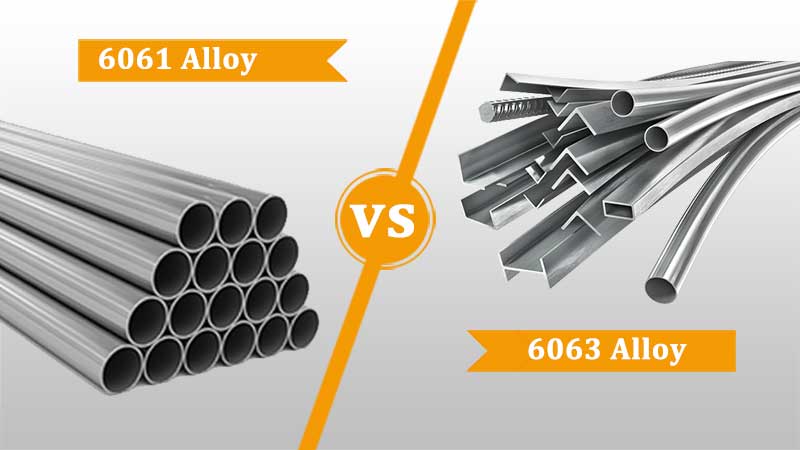

Aluminum (Al) is a highly versatile metal that’s widely implemented across industries. Among many top-tier aluminum alloys, 6061 and 6063 from the 6xxx series have been two of the most popular choices.

The two alloys share several similarities, coming from the same alloy category. However, each aluminum alloy has distinct advantages in terms of strength, finish quality, weldability, and cost-effectiveness.

Understanding the to-the-point differences between 6061 and 6063 is mandatory for an informed decision. This article breaks down the key differences, properties, and ideal use cases of 6061 vs 6063 aluminum.

6061 Aluminum: An Overview

It’s one of the most produced + consumed aluminum alloys in North America, Europe, and Asia-Pacific. 6061, a heat-treatable alloy (structural aluminum for construction projects), is primarily alloyed with –

- Aluminum (Al): 95.8% – 98.6%.

- Magnesium (Mg): 0.8% – 1.2%

- Silicon (Si): 0.4% – 0.8%.

- Iron (Fe): ≤ 0.7%.

- Copper (Cu): 0.15% – 0.4%.

- Chromium (Cr): 0.04% – 0.35%.

- Zinc (Zn): ≤ 0.25%.

- Titanium (Ti): ≤ 0.15%.

- Manganese (Mn): ≤ 0.15%.

6061 Aluminum Features: Mechanical and Physical Properties

- High Strength-to-Weight Ratio: It marks a tensile strength of 290 MPa (42,000 psi) and yield strength of 241 MPa (35,000 psi) in the T6 temper.

- Good Corrosion Resistance: 6061 can thrive in marine and humid environments due to its protective oxide layer.

- Good Weldability: 6061 can be welded using the most common techniques without compromising structural integrity.

- Superior Machinability: It machines well in both annealed and heat-treated conditions for precision components.

- Heat Treatable: 6061 can be further strengthened through precipitation hardening (T6 temper).

- Good Surface Finish: The alloy even goes well with anodizing for aesthetic and protective finishes.

Applications of 6061 Aluminum

- Construction: Structural framing, roofing, and bridges benefit from 6061. It’s used in curtain walls, window frames, and roof structures. The fatigue strength suits structural applications with good workability.

- Automotive Applications: 6061 is common in chassis, wheels, and engine components for performance and fuel efficiency. EV manufacturers, including Tesla, use 6061 for battery enclosures and body panels.

- Aerospace / Aviation: 6061 has a high demand in aircraft fuselages, wings, and spacecraft components. NASA has employed it in spacecraft structures due to its strength and resistance to stress cracking.

- Consumer Products: The aluminum alloy is popular in bicycle frames, fishing rods, ladders, and furniture. Many high-performance mountain bikes use 6061-T6 aluminum for its balance of strength and weight.

- Industrial Applications: The material seems ideal for piping, valves, and marine fittings. 6061 also has uses in offshore platforms and boat hulls due to its corrosion resistance in saltwater environments.

6063 Aluminum: An Overview

The alloy belongs to the Al-Mg-Si (aluminum-magnesium-silicon) family. It’s the most commonly used alloy for aluminum profiles. A standard 6063 composition and mechanical properties include –

- Aluminum (Al) = 98.9%.

- Magnesium (Mg) = 0.45% – 0.9%.

- Silicon (Si) = 0.2% – 0.6%.

- Iron (Fe) = ≤ 0.35%.

- Copper (Cu) = ≤ 0.1%.

- Manganese (Mn) = ≤ 0.1%.

- Chromium (Cr) = ≤ 0.1%.

- Zinc (Zn) = ≤ 0.1%.

- Titanium (Ti) = ≤ 0.1%.

Aluminum 6063 (T6) Features: Physical and Mechanical Properties

- Excellent Extrudability: It’s easy to form 6063 into intricate profiles for window frames, door frames, and tubing.

- Superior Surface Finish: 6063 accepts anodizing exceptionally well. It results in a clean and attractive appearance.

- Moderate Strength: Tensile strength ranges from 145 MPa (21,000 psi) in T5 temper to 190 MPa (28,000 psi) in T6.

- Good Weldability: 6063 performs well across welding applications without significant loss of strength.

- Corrosion Resistance: The common alloy resists corrosion in outdoor environments when soft anodized.

- Heat Treatable: 6063 aluminum can be strengthened through aging processes (T5 and T6 tempers).

Applications of 6063 Aluminum

- Architecture: It’s extensively used in window frames, door frames, curtain walls, and railings. 6063 is favored for high-rise building facades in Europe and the Middle East due to its anodized finish.

- Transportation: 6063 is found in railings, roof racks, and trim components to prioritize form and corrosion resistance. Japanese bullet trains use it for interior trim and framing due to its clean finish.

- Industrial + Consumer Products: It has uses in piping, tubing, furniture, display frames, and light fixtures. LED lighting housings (electrical components) use 6063 for its thermal conductivity and anodized finish.

- Marine Applications: The alloy serves excellently for boat trim, dock railings, and marine enclosures. Its corrosion resistance in saltwater environments remains a highly beneficial factor in such cases.

6061 vs 6063: Key Differences

- Alloy Composition

The presence of copper in 6061 noticeably enhances the mechanical strength through precipitation hardening. However, excess copper slightly reduces corrosion resistance in aggressive environments.

Therefore, the absence of copper in 6063 results in lower strength compared to 6061. However, it offers superior corrosion resistance and excellent anodizing properties to suit architectural installations.

- Strength (Hardness)

The tensile strength is 310 MPa for 6061, which gets to 240 MPa with 6063. Their yield strength values are 276 MPa and 214 MPa, respectively. Even the Brinell Hardness is 95 for 6061 and 73 for 6063.

6061 is significantly stronger and harder than 6063. No wonder it gets preference for high-stress cases. While adequate for moderate loads, it’s better suited for non-load-bearing or aesthetic uses.

- Aluminum Extrusion Projects

6063 is well-recognized for its superior extrudability. It enables smooth surface finishes for complex shapes and thin-walled designs (recreational equipment).

Such superiority makes the alloy perfect for windows, door frames, curtain walls, and decorative trims. 6063 accounts for 85% of architectural aluminum extrusions.

- Machinability and Weldability

Meanwhile, 6061 comes with excellent machinability and weldability. It can undergo CNC machining, structural assemblies, and custom mechanical parts.

It maintains dimensional stability under stress, which is critical for precision engineering. 6063, while machinable, is more prone to deformation in tight tolerances.

- Corrosion Resistance

Both alloys perform well in general environments. 6063 has slightly better natural corrosion resistance due to its lack of copper, which can reduce resistance in 6061.

For chemically aggressive environments, anodizing or protective coatings are recommended. Anodized 6063 is widely used for window frames and railings in coastal construction.

- Thermal and Electrical Conductivity

The thermal conductivity counts 166 W/m·K for 6061, which becomes 201 W/m·K with 6063. Meantime, their respective electrical conductivity values stand at 43% IACS for 6061 and 52% IACS for 6063.

Low Cu gets 6063 a higher thermal conductivity to suit transportation components in motor vehicles. 6061 has a lower melting temperature (lower thermal conductivity) based on alloying elements.

- Surface Finish (Aesthetics)

6063 is widely known as the “architectural alloy” due to its fine-grain structure. It directly contributes to a smoother surface post-extrusion. The alloy responds well to anodizing to produce a uniform, glossy, and corrosion-resistant finish.

6061 tends to produce a matte, slightly rougher surface after extrusion. The anodized finish may appear less uniform, with potential for streaks or cloudy patches. However, 6061 performs better with powder coating with masked imperfections.

- Cost Considerations

6061 is a premium due to its increased strength from the extrusion process for various applications. The hard and strong material requires more robust tooling, slower machining speeds, and higher energy input.

6063 is 5% – 15% less expensive than 6061, depending on region and market conditions. It enables fast yet low-energy extrusion, reducing production costs. 6063’s softness means less tool wear and faster cycle times.

6061 vs 6063 Aluminum: Comparison Table

6063 vs 6061: How to Choose the Right One?

Selecting the right option from the two aluminum alloys relies on project scale, regional manufacturing, and lifecycle expectations. Even your aesthetic priorities may alter the ultimate choice in many cases.

- Lifecycle Optimization

Material selection is heavily influenced by the total lifecycle cost rather than upfront pricing. Large-scale infrastructure projects like urban transit systems in Europe or Asia follow the rule.

Alloy selection for rail station cladding in Tokyo prioritized long-term weather resistance and minimal maintenance. The alloy’s ability to retain finish quality in high-humidity zones was a decisive factor.

- Manufacturing Compatibility

Extrusion with good machinability is optimized for high-volume architectural profiles. The local supply chain mostly favors alloys that align with fair machinability characteristics for different applications.

High-strength aluminum extrusions (6061) have lower heat capacity for building applications. Good surface quality following the heat treatment process suffices for mass-produced items like sign frames.

- Structural Integration vs Modular Design

Modular construction, like prefabricated housing, is gaining momentum in Africa and Southeast Asia. Aluminum is increasingly used there for lightweight framing and paneling.

The choice is influenced by how well it integrates with composite materials, fasteners, and thermal insulation. Alloys with dimensional stability across temperature fluctuations and compatibility with adhesives/sealants get selected.

- Renewable Energy Expansion

Aluminum alloys continue to receive favors for panel frames, mounting systems, and inverter housings. China leads the world in solar panel production. The selection is driven by thermal conductivity, ease of anodizing or powder coating, and UV resistance.

The global push towards renewable energy does not just focus on mechanical strength. The alloy’s ability to maintain reflectivity and resist oxidation in outdoor installations is obligatory.

- Lightweight Mobility Solutions

The European e-bike market rests on weight management and aesthetic design. Manufacturers choose alloys based on ride feel, frame flexibility, and paint adhesion.

For example, Dutch and German brands prioritize alloys that allow for sleek hydroformed tubing and consistent powder coating. Such measures ensure performance and showroom appeal.

- Urban Design and Sustainability

Aluminum remains at the core of green building certifications in cities like Dubai or Singapore City. Alloy selection is influenced by recyclability, embodied energy, and LEED compliance.

Alloys that offer high post-consumer recycling rates and low carbon footprints during extrusion are increasingly favored, even if they require more careful handling during fabrication.

Frequently Asked Questions (FAQs)

- Can 6061 and 6063 be used interchangeably in projects?

Not always. 6061 is better for structural strength, and 6063 excels in surface finish. Substituting one for the other may compromise performance or aesthetics, depending on the application.

- Which alloy is better for anodizing in colored finishes?

6063 is preferred for colored anodizing due to its smoother surface and constant oxide layer formation. It directly results in more vibrant and uniform colors.

- Is either alloy suitable for load-bearing architectural elements?

6061 is more suitable for load-bearing elements like beams or brackets. It’s especially beneficial in commercial buildings, due to its higher yield strength.

- Which alloy is more resistant to stress cracking?

6061 has better resistance to stress cracking under cyclic loads. That’s why it sees increased use in aerospace and automotive components.

- Can both alloys be used in bolted or riveted assemblies?

Yes. However, 6061 is preferred when mechanical fastening is involved. It’s because 6061 can maintain integrity under torque and shear forces better than 6063.

- Which alloy is better for DIY machining or hobbyist projects?

6061 is more forgiving for DIY machining. The hardness and dimensional stability suit small-scale but standard processing, especially in CNC setups.

- How do these alloys perform in extreme temperatures?

6061 performs better in high-temperature environments due to its thermal stability. Meanwhile, 6063 may soften more quickly under prolonged heat exposure.

Conclusion

Your choice between 6061 and 6063 aluminum shouldn’t come from technical specs alone. 6061 stands out for its structural performance with strength and durability. Whereas, 6063 shines in visual appeal + formability with smooth finishes and intricate extrusions.

Get Top-Tier Aluminum Alloy Products at HONJENNY

Honjenny has been a top aluminum brand with careful implementation to match your needs. We have been thriving through innovation, commitment, and precision for 30 years. Contact us to know further.