Precision Zinc Die Casting Services (Zamak 3, 5, ZA-8)

Specializing in high-precision, thin-wall zinc components with superior chrome plating and surface finishing. ISO 9001 & IATF 16949 Certified Manufacturer.Contact Now!

Our Manufacturing Capabilities

Zinc Alloys Selection

In-House Mold Making

High-Pressure Die Casting

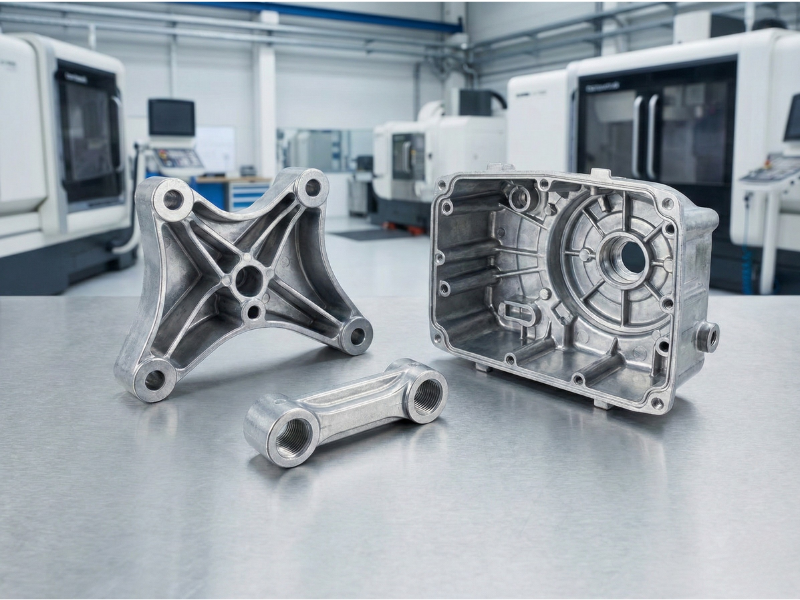

CNC Machining

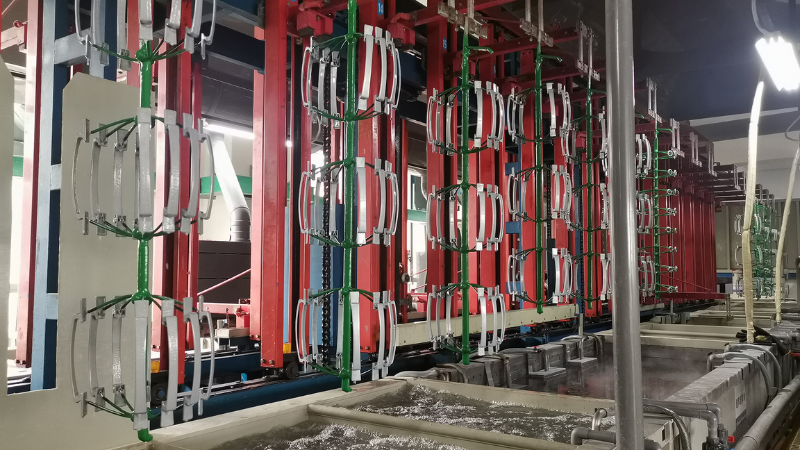

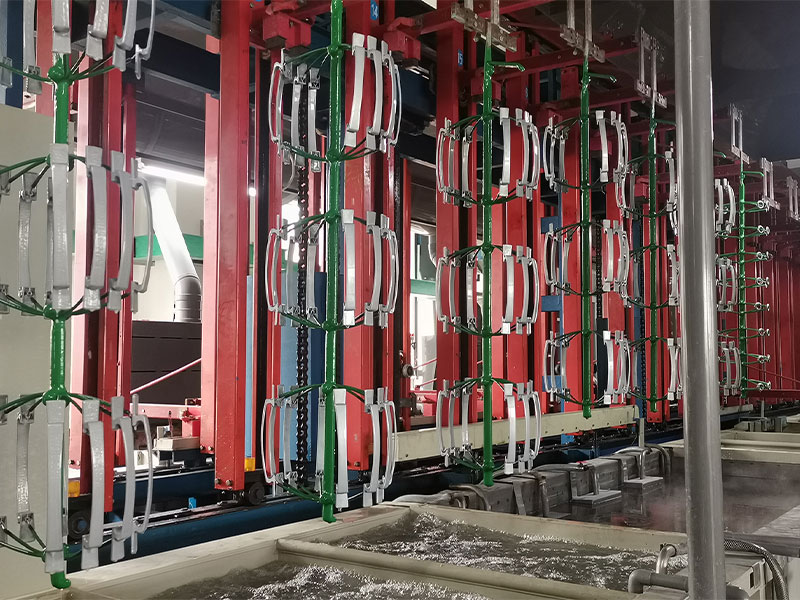

Premium Surface Finishing

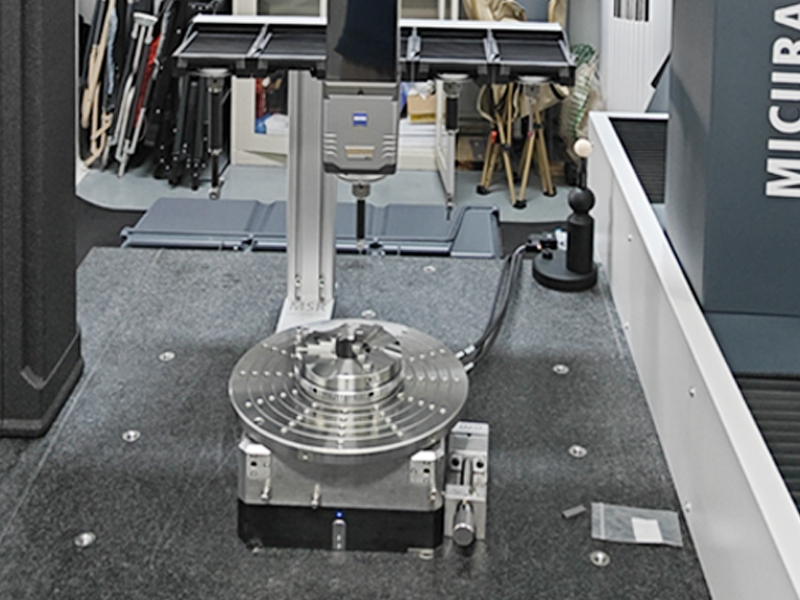

Quality Inspection

Ready to Kickstart Your Project?

Why Choose Zinc Die Casting?

Zinc alloys offer the ideal balance of mechanical strength, precision capabilities, and cost-effective tooling compared to aluminum and magnesium.

Complex Geometries

Superior fluidity allows for thinner walls (down to 0.5mm) and tighter tolerances without secondary machining.

Superior Finishing

The best substrate for plating. We achieve mirror-like Chrome, Nickel, and Powder Coating finishes easily.

Longer Tool Life

Lower melting points mean zinc molds last up to 10x longer than aluminum molds, saving your tooling costs.

Industries We Serve

Delivering high-quality zinc components for global brands in critical sectors.

Your Trusted Zinc Die Casting Partner

With over 29 years of experience, we combine advanced hot-chamber technology with strict quality control to deliver defect-free parts

-1.jpg)

What Our Clients Say

Customer satisfaction is at the core of our business. We take pride in building long-term partnerships by consistently delivering defect-free zinc die casting parts on time.

Our Production Process

From design optimization to final delivery, we handle every step.

01

02

03

Frequently asked questions

We minimize porosity by optimizing the runner and overflow design during the mold flow analysis phase. We also use advanced hot-chamber machines with precise pressure control and offer X-ray inspection to ensure internal structural integrity.

Zinc is the best substrate for plating. We ensure adhesion through strict pre-treatment and cleaning processes. We perform cross-cut adhesion tests and Salt Spray Tests (up to 72 hours) to guarantee corrosion resistance for outdoor or bathroom environments.

Zinc casting is highly precise. We can achieve “As-Cast” tolerances of ±0.05mm for most features. For critical dimensions requiring tighter limits (±0.01mm), we use our in-house CNC machining centers to ensure perfect fitment.

This is a major advantage of zinc. Because of zinc’s lower melting point, thermal shock is reduced. Our zinc molds typically last from 500,000 to 1,000,000 shots—up to 10 times longer than aluminum molds—reducing your long-term amortization costs.

We are flexible. We support low-volume pilot runs (e.g., 500-1,000 pcs) to help you launch your product. However, zinc die casting is most cost-effective at higher volumes (5,000+ pcs) due to the high speed of production.

Zinc’s high fluidity allows for incredibly thin walls. We can cast walls as thin as 0.5mm to 0.8mm, which helps reduce part weight and material cost while maintaining structural rigidity.