Premium Surface Finishing Solutions

Transform your Honjenny die castings into market-ready products. We offer a complete range of finishing services to enhance corrosion resistance, surface hardness, and visual appeal.Contact Now!

Our Surface Treatment Capabilities

Shot Blasting

Precision Sandblasting

Coating & Wet Painting

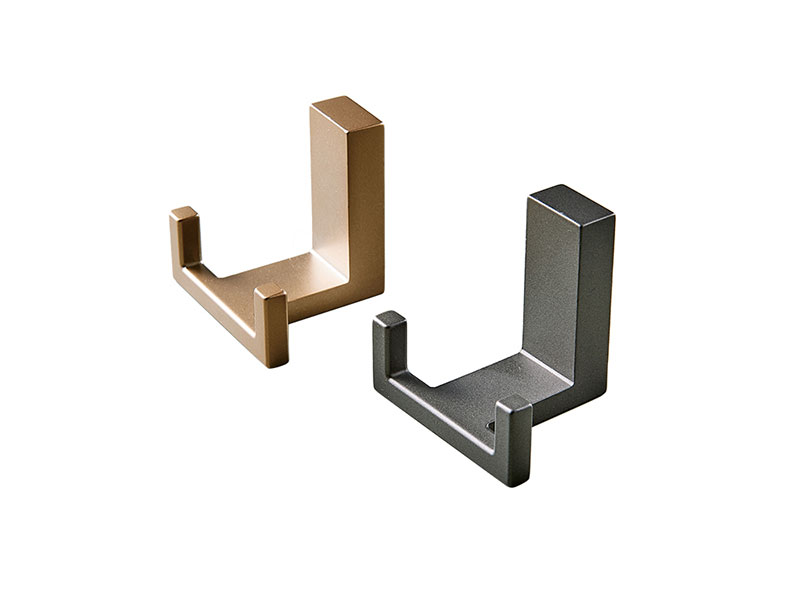

Anodizing

E-Coating (Electrophoresis)

Electroplating (Chrome/Nickel/Zinc)

Give Your Products the Perfect Finish

The Honjenny Finishing Standard

We ensure the coating adheres perfectly to the casting.

Superior Adhesion

We control the substrate quality. By ensuring the raw casting is clean and porous-free, we guarantee coatings pass the Cross-Cut Tape Test (ISO 2409).

In-House Validation

Every batch undergoes strict testing in our lab, including Salt Spray Testing (up to 720+ hours) and coating thickness measurement.

Visual Consistency

We use colorimeters to ensure ΔE < 1.0, guaranteeing that parts from different batches look exactly the same when assembled.

Finishing Applications

Meeting the visual standards of Consumer Electronics and the durability standards of Automotive industries.

Verified Quality Assurance

At Honjenny, surface finishing is science, not art. Our Quality Lab is equipped to verify that our finishes can withstand the harshest environments.

-1.jpg)

Customer Success Stories

Feedback on our finish quality.

Finishing Workflow

Ensuring the look you want.

01

02

03

Frequently asked questions

Yes, for Powder Coating and Wet Painting, we can match any RAL or Pantone color code. For Anodizing, we offer standard colors (Black, Natural, Red, Blue, Gold).

It depends on the process. Our standard Powder Coating passes 500-1000 hours. Zinc Plating typically passes 48-96 hours (up to 240h with sealer). E-coating passes 500+ hours.

Yes, all our surface treatments, including Trivalent Chromate (Cr3+) plating and lead-free paints, are fully RoHS and REACH compliant for global markets.

Yes, but ADC12 contains high Silicon content, which turns the surface dark or yellowish-grey during anodizing. It is excellent for corrosion protection but not recommended for cosmetic parts requiring a clear, bright, or uniform metallic finish. We can advise on the best alloy or alternative finish for your visual needs.

Typically 60-80 microns, but we can adjust this based on your assembly tolerances.

Absolutely. Honjenny designs custom silicone plugs and masking fixtures to ensure threads and grounding points remain free of paint/plating.