High Precision Casting Molds Built for Stable Efficient Production

Reduce trial cycles, avoid defects and achieve consistent mass production with durable, high accuracy molds engineered to lower your costs and shorten your lead time.Contact Now!

Complete Mold Manufacturing Process

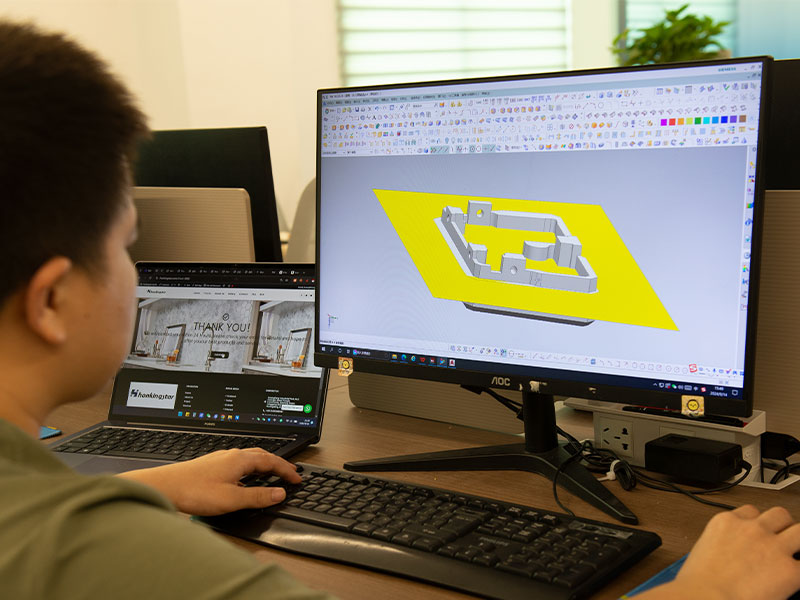

Mold Design

CNC Machining

EDM Forming

Wire Cutting

Heat Treatment

Mold Assembly

Start Your Casting Mold Project Today

Honjenny Mold Manufacturing Advantages

Honjenny builds casting molds with stable performance and reliable accuracy. With proper design and maintenance, most molds support many thousands of opening cycles for dependable production.

Precision Mold Engineering

We solve early design risks with expert DFM, optimized gating and cooling layouts, ensuring fewer defects and smoother mass production for your casting projects.

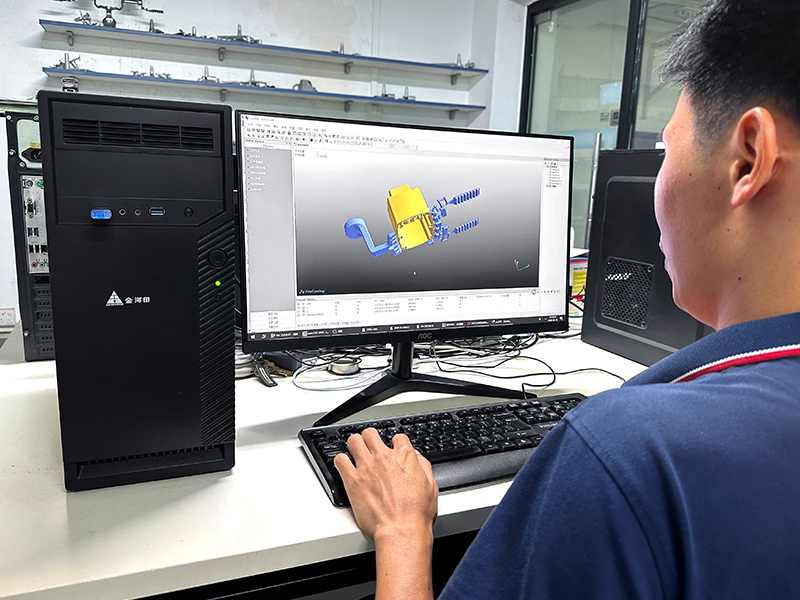

Tight Tolerance Manufacturing

With advanced CNC, EDM, and wire cutting, we build molds with tight tolerances and perfect component fit to eliminate leaks, misalignment, and maintenance issues.

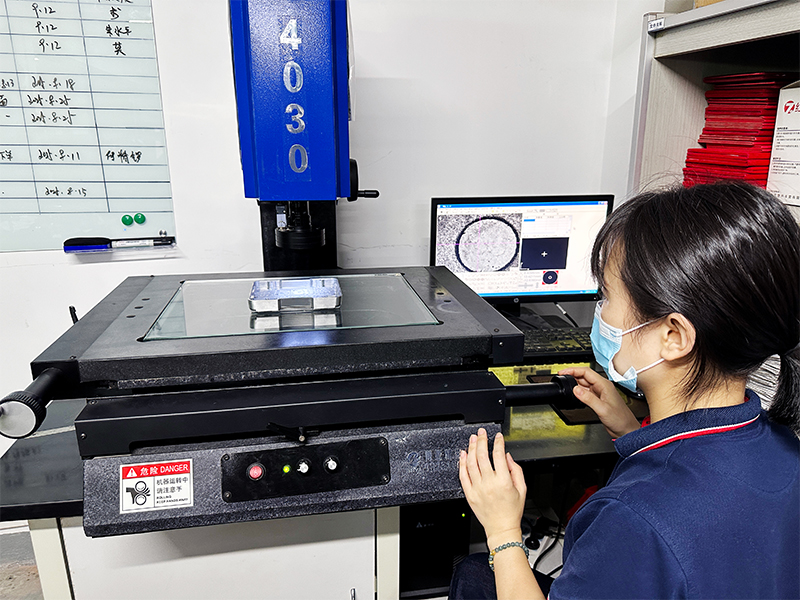

Reliable Trial & Validation

Our T0–T2 trials identify and refine defects like porosity, warpage, and filling issues, delivering production-ready molds with repeatable, stable casting quality.

Types of Casting Molds We Build

We support a wide range of mold structures, from multi-slide and insert molds to deep-cavity and thin-wall tooling, designed for complex casting geometries and stable production performance.

Why Choose Honjenny Casting Molds

Our molds are built for stable performance, consistent accuracy, and dependable production, helping you reduce defects and launch projects with confidence.

-1.jpg)

What Customers Say About Our Casting Molds

Real feedback from clients who faced common issues in mold design, accuracy, and delivery and found reliable solutions through Honjenny’s casting molds.

How We Work Together on Your Casting Mold

A clear and efficient three-step process that brings your casting mold from initial drawings to a fully validated, production-ready tool.

01

02

03

Frequently asked questions

We only need your 3D/2D drawings, annual volume expectation, material requirements, and any special tolerance or surface needs. This helps us provide an accurate and meaningful quote—avoiding low-quality or misleading estimates.

Yes. We can perform a full feasibility check and provide DFM insights for gating, cooling, and parting layout. This helps identify potential risks such as porosity, filling issues, or early wear before the mold is built.

Depending on complexity, most casting molds take 3–6 weeks, including machining, assembly, and T0–T2 trial runs. Highly complex molds may take longer, but we confirm the schedule before production begins.

With CNC, EDM, and wire cutting, we typically achieve tight tolerances suitable for precision housings and structural parts. For high-accuracy sections, we follow your drawing requirements and validate critical features during trials.

We use 8418 hot-work tool steel for all casting molds. It offers better toughness and heat-crack resistance than standard grades like H13, making it suitable for stable long-term die casting production.

Yes. Every casting mold goes through structured T0–T2 trials. We identify dimensional deviations, filling issues, and surface defects, then make adjustments to ensure the mold reaches stable production performance before delivery.