Precision Aluminum Die Casting for Reliable Production

Eliminate porosity, reduce rework, and achieve consistent batch accuracy. Honjenny provides 100–1800T aluminum die casting with ±0.005 mm machining and full CMM/X-ray inspection.Contact Now!

Our Aluminum Die Casting Capabilities

100–1600T Die Casting Capacity

Aluminum Alloys for Diverse Needs

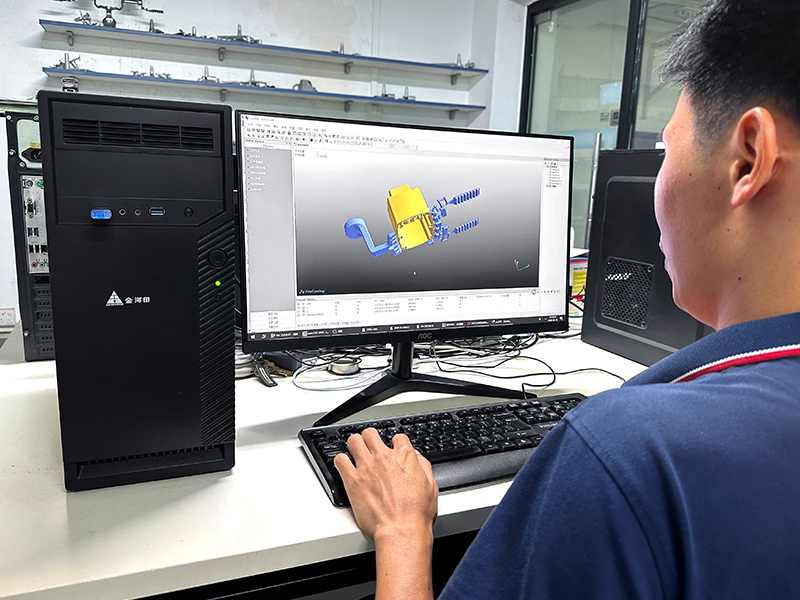

In-House Tooling & DFM Support

±0.0015 mm CNC Machining

Complete Finishing Solutions

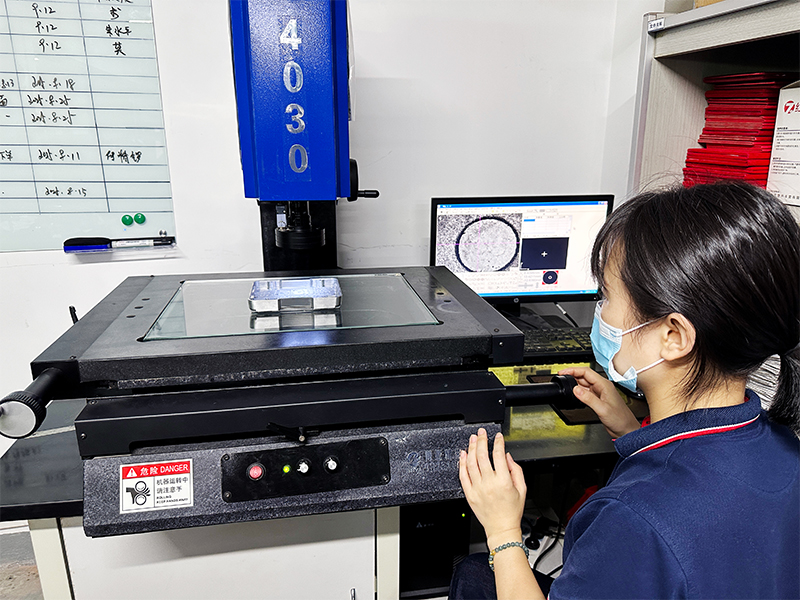

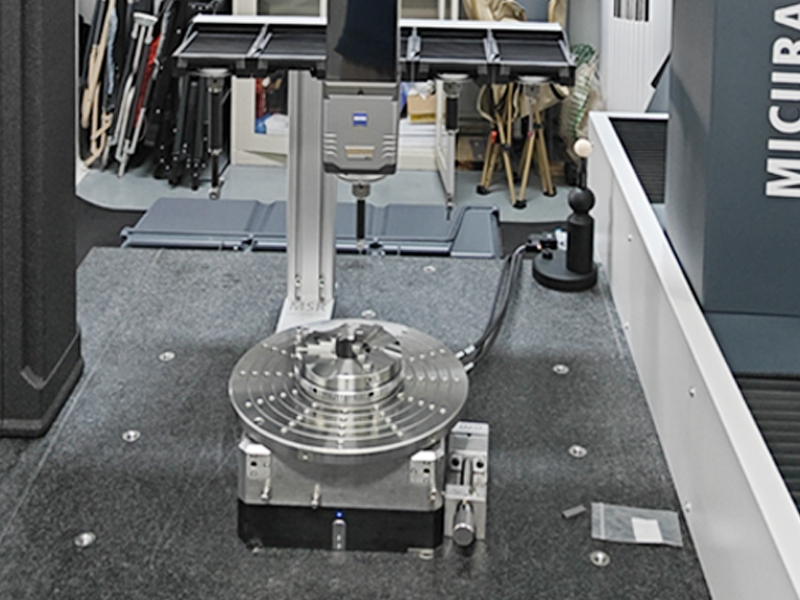

CMM & X-Ray Quality Assurance

Start Your Aluminum Die Casting Project Today

Why Choose Honjenny for Aluminum Die Casting

We deliver stable, precise, and efficient aluminum die casting backed by strong capacity and in-house production.

Wide Tonnage Range

100–1600T machines support simple housings to large structural parts, ensuring stable geometry and thin-wall capability.

Reliable Batch Consistency

CMM, X-ray, and strict in-process control help prevent porosity, maintain tight tolerances, and ensure repeatable quality.

Fully Integrated Production

In-house tooling, die casting, machining, and finishing deliver faster lead times and smoother project execution.

Our Manufacturing Strength in Aluminum Die Casting

We operate a fully equipped facility with high-pressure die casting machines, CNC centers, and complete inspection systems to support stable, large-scale aluminum production.

A Trusted Aluminum Die Casting Manufacturer

Specializing in aluminum die casting, we ensure stable quality and precise dimensions through integrated tooling, machining, and inspection.

-1.jpg)

What Our Clients Say

Trusted by global partners, Honjenny delivers consistent quality, responsive communication, and reliable project execution in aluminum die casting.

How We Work With You

A clear three-step process that keeps projects efficient, predictable, and easy for you from the initial inquiry to final delivery.

01

02

03

Frequently asked questions

Porosity is controlled through optimized gating design, stable die-casting parameters, vacuum venting where needed, and X-ray/CMM checks during sampling. We adjust the tool and process until the density meets your requirements.

We review your CAD during DFM and evaluate filling, cooling, and ejection conditions. Critical sections receive extra support through rib optimization, mold-flow simulation, and machining of tight areas after casting if required.

Tooling is fully designed and built in-house. We control steel selection, heat treatment, venting, and cooling layout. With internal machining and polishing teams, tooling adjustments are fast and precise.

Surface defects like flow marks, cold shuts, or micro-porosity often appear on cosmetic surfaces.

We control metal flow, optimize gate position, and use shot-blasting/polishing processes to achieve uniform finish. For demanding applications, we apply stricter process windows.

Many aluminum products fail because risks are not identified early.

Our engineers review your drawings before tooling, highlight potential casting issues, and provide practical DFM suggestions to prevent defects and reduce tooling iterations.

Yes. We can provide part marking, batch codes, material certificates, production records, and inspection reports. This ensures every component can be traced back to its production batch and quality data.

Yes. We support PPAP Level 1–3, including dimensional reports, material certifications, control plans, and capability studies (CP/CPK). Our quality team follows automotive-grade standards for stable and traceable mass production.