Metal casting lies at the core of modern manufacturing. It transforms molten metal into functional parts for countless industries. Casting enables complex geometries with accuracy and repeatability.

Among many casting methods, investment casting and die casting remain at the forefront of choices. Each casting presents distinct features to deliver specific advantages for particular use cases.

Explore the key differences between die casting and investment casting through this article. You can understand what aspects set the two versatile, highly implemented, and top casting methods apart.

Metal Casting Methods: Where Do Die Casting and Investment Casting Stand?

The standard metal casting process involves pouring molten metal into a mold to form solid parts with intricate shapes and tight tolerances. Manufacturers often rely on other casting processes to meet specific production needs. Common casting methods –

- Sand Casting: Cost-effective and flexible for large parts, but less precise.

- Investment Casting: Exceptional detail and surface finish for complex shapes + thin walls.

- Die Casting: High-speed and high-volume production with high dimensional accuracy.

- Centrifugal Casting: Exclusive method for cylindrical parts like pipes and bushings.

- Shell Mold Casting: Superior surface finish and accuracy when combined with sand casting.

Investment casting is popular for low-to-medium volume production of intricate parts. It holds a growing demand across aerospace, medical devices, and defense.

Die casting is the best for high-volume production of parts with consistent quality. It’s the gold standard for automotive components, consumer electronics, and other goods.

Investment Casting Overview

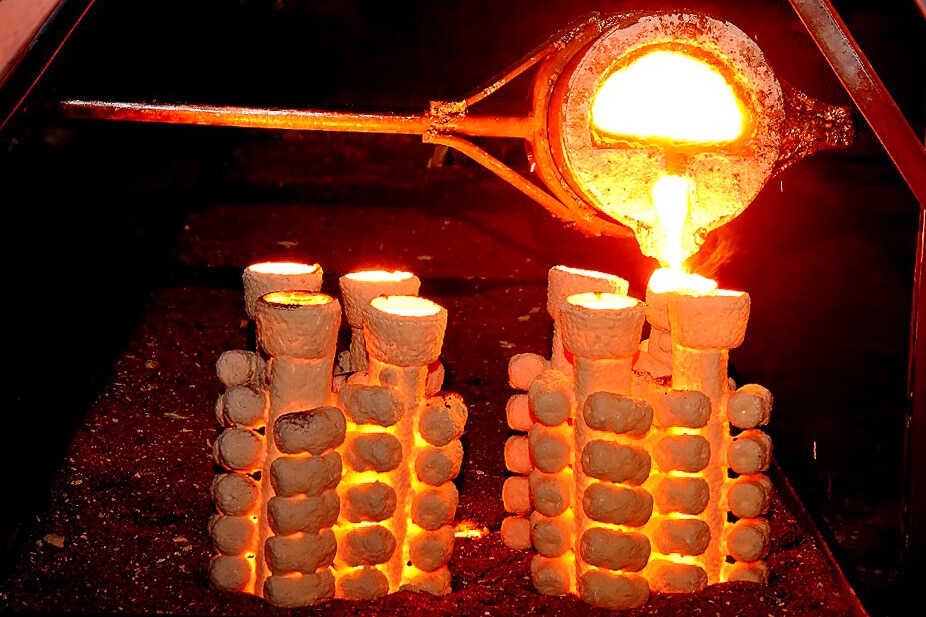

Investment casting also goes by lost-wax casting. A wax pattern, coated with a ceramic shell, is used to create a mold. The wax is melted out, and molten metal is poured into the cavity to form the final part.

The term ‘investment’ refers to the ceramic slurry that invests or surrounds the wax pattern. Traditional investment casting has been in practice for 5,000+ years, and that still remains crucial across industries.

Investment Casting Process: Step-by-Step

- Wax Pattern Creation: A wax replica of the final part gets made using injection molding.

- Assembly: Multiple wax patterns are attached to a central wax sprue to form a ‘tree’.

- Shell Building: The wax tree is repeatedly dipped in ceramic slurry. Then, it gets coated with sand to build a hard shell.

- Dewaxing: The ceramic-coated wax assembly is heated to melt and drain the wax. It leaves a hollow mold.

- Firing: The ceramic mold is fired at high temperatures for strengthening and the removal of residual wax.

- Metal Pouring: Molten metal is poured into the preheated mold.

- Cooling + Shell Removal: After proper solidification, the ceramic shell is broken away.

- Cutting and Finishing: Individual castings are cut from the tree. They undergo finishing like grinding, machining, or heat treatment.

Common Investment Materials

- Stainless steel

- Carbon steel

- Aluminum

- Titanium

- Nickel-based alloys

- Cobalt-based alloys

Such flexibility regarding material selection makes investment casting a highly preferred choice. More specifically, it’s rather suitable for ferrous and non-ferrous applications across industries.

Key Features of Investment Casting

- Tight tolerances: ±0.005 inches or better.

- Excellent surface finish: Ra 3.2 – 6.3 µm

- Complex geometries: Thin walls, undercuts, and internal cavities.

- Minimal waste: Near-net-shape reduces machining.

- Scalable: Suitable for low to medium production volumes.

Investment Casting Advantages

- Design freedom: Great for intricate but high-precision parts.

- Material versatility: Works with exotic and high-performance alloys.

- Reduced machining: Saves time and cost in post-processing.

- Superior surface quality: Often eliminates the need for polishing.

- Consistency: Excellent repeatability across multiple batches.

Potential Limitations

- Higher cost per part compared to sand casting or die casting.

- Longer lead times due to mold preparation and shell building.

- Not ideal for high-volume production due to many constraints.

- Size limitations as mostly suitable for small to mid-sized parts.

Common Applications

- Aerospace: Turbine blades, fuel nozzles (GE Aviation).

- Automotive: Engine components, turbocharger wheels.

- Medical: Orthopedic implants, surgical tools.

- Defense: Firearm components, missile parts.

- Industrial machinery: Pumps, valves, impellers.

Rolls-Royce depends on investment casting to produce single-crystal turbine blades. Investment-cast parts are well capable of withstanding extreme temperatures in jet engines.

Die Casting Overview

Molten metal gets forced (injected) into a precisely machined steel mold (die) under high pressure. It’s extensively preferred for complex yet dimensionally accurate components with smooth surface finishes.

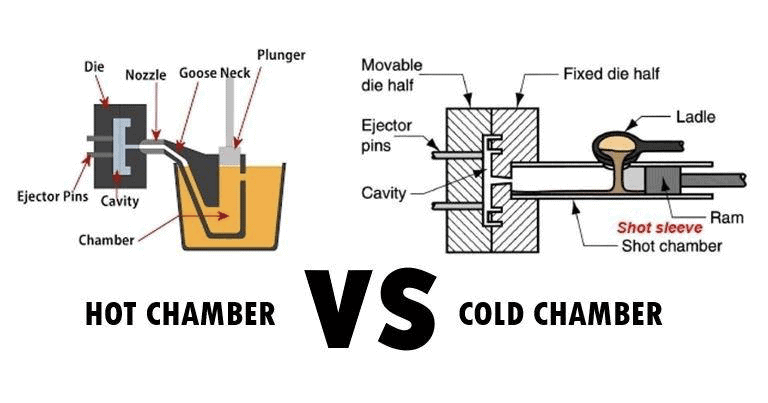

Even low-pressure die casting exists, which involves minimal post-processing. The manufacturing process is like the universal choice due to speed and scalability. Also, there are two primary die casting types –

- Hot chamber die casting: Suitable for low-melting-point metals like zinc and magnesium.

- Cold chamber die casting: Good for higher-melting-point metals like aluminum and copper.

Die Casting Process: Step-by-Step

- Die Preparation: The steel mold is cleaned and lubricated.

- Metal Melting: The intended metal gets melted in a furnace.

- Injection: Molten metal is injected into dies at high pressure.

- Cooling: The poured metal solidifies quickly inside the die.

- Ejection: The die gets opened to remove the desired shape.

- Trimming: Any excess surface material (flash) gets removed.

- Finishing: Die-cast parts may require machining or coating.

Modern die casting machines can complete a cycle in under 10 seconds. Such speed makes the manufacturing process one of the fastest compared to other casting methods.

Common Die Casting Material

- Aluminum: Lightweight and corrosion-resistant.

- Zinc: Excellent fluidity and strength.

- Magnesium: Lightest structural metal.

- Copper alloys: High strength and conductivity.

Aluminum and zinc die casting dominate the global market due to their balance of strength, weight, and cost-effectiveness.

Key Die Casting Features

- High accuracy: Tolerances as tight as ±0.1 mm.

- Thin-walled sections: Down to 0.5 mm.

- Smooth surface finish: Ra 0.8 µm or better.

- Fast cycle times: Ideal for high-volume production.

- Repeatability: Consistent quality across parts.

Benefits of Die Casting

- Speed: Rapid production cycles reduce lead times.

- Cost-efficiency: Low per-unit cost for large volumes.

- Design flexibility: Intricate shapes with fine details.

- Material savings: Minimal waste due to near-net-shape casting.

- Lightweight parts: Substitution of steel with aluminum or magnesium

Aluminum die casting creates complex parts that can effectively reduce the weight by 30% – 50% in the aerospace and automotive industry.

Concerning Limitations

- Die creation is expensive and time-consuming.

- Limited to non-ferrous metals (not for steel or iron).

- Air entrapment can affect structural integrity.

- Not for low-volume production on economic scales.

Notable Die-Cast Applications

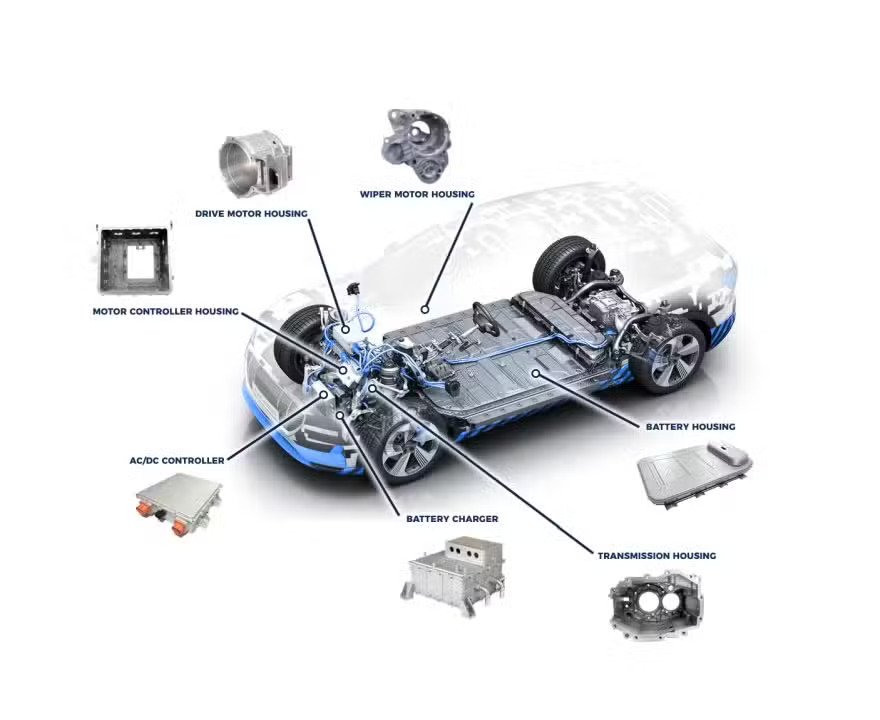

- Automotive: Engine blocks, transmission housings, brackets.

- Electronics: Housings, connectors, heat sinks.

- Consumer goods: Appliance parts, power tools, camera bodies.

- Industrial equipment: Pumps, gearboxes, enclosures.

The global die casting market is projected to exceed $100 billion by 2030. The growing demand comes from high-performance components in EVs and smart devices.

Investment Casting vs Die Casting: Key Differences

- Production Speed

Molten metal fills hardened steel molds under high pressure in die casting. The die cavity produce parts at high volume production runs. Expect precise components for every desired part. The process may require a minimum of 10 seconds to complete a full cycle.

Investment casting implements a wax pattern coated in refractory ceramic material to form a mold. The wax is melted out, and molten metal is poured into the mold cavity. The slower process is also labor-intensive, which allows exceptional detailing with flexibility.

- Precise Surface Finish

Investment casting produces a smoother surface finish (Ra 3.2 – 6.3 µm) due to the fine ceramic mold. It effectively reduces or eliminates the need for post-processing.

Meanwhile, die casting also delivers good surface finishing (Ra 1.6–6.3 µm). However, the surface may need additional polishing or machining for aesthetic purposes.

- Material Compatibility

Investment casting can accommodate many materials (ferrous alloys, stainless steel, titanium, and nickel-based superalloys). The process seems superior when material performance is critical.

Die casting remains limited to non-ferrous metals like aluminum, zinc, and magnesium. Those metals can handle the high-pressure injection process to deliver excellent strength-to-weight ratios.

- Design Complexity

Investment casting is good at crafting complex geometries, thin walls, and intricate internal cavities. You can expect tight tolerances (±0.005 inches) and superior surface finishes. The method gets preference when machining seems impractical or costly.

Die casting also enables good dimensional accuracy (±0.1 mm) and smooth surfaces. However, it’s less suited for extremely intricate or sensitive designs. However, die casting still supports thin-walled parts and fine details for high-volume production.

- Tooling and Setup Cost

Die casting requires high upfront tooling costs, which may exceed $50K – $100K for complex dies. The hardened steel molds are durable but still expensive to produce.

In contrast, investment casting relies on wax patterns and ceramic shells. It results in lower tooling costs, making the method more accessible to rapid prototyping of parts.

- Cost per Part

Die casting may have high initial costs, but its cost per part drops significantly with volume. That’s why it remains the go-to choice for automotive and consumer electronics.

Investment casting has higher per-unit costs due to labor and time. However, it becomes cost-effective for complex and low-volume parts that otherwise require extensive machining.

- Environmental and Sustainability Factors

Investment casting involves wax and ceramic waste. Then, there are burnout and firing stages that consume significant energy. However, you can reclaim the refractory material for a new wax pattern. The versatile process even grants efficiency for exotic alloys.

Die casting is more energy-intensive, especially in cold chamber systems used for aluminum. However, it generates less material waste due to near-net-shape production. High recyclability also prevails for aluminum and zinc.

Investment vs Die Casting: Summary Comparison

How to Choose the Right Casting: Die vs Investment Casting?

Your preference/choice regarding the ultimate casting method depends on your priorities. Specifically, your project specifications will decide the process for engineers and designers.

- Production Cost or Volume

Die casting is ideal for high-volume production (10,000+ units/month) due to fast cycle times (as low as 10 seconds per part) and low cost per unit. Investment casting is more cost-effective for smaller batches of low-to-medium volume (100 – 5,000 units/month).

- Material Requirements

Non-ferrous metals like aluminum, zinc, and magnesium should go for die casting. Die-cast parts excel in lightness and corrosion resistance. Only investment casting supports ferrous and exotic alloys like stainless steel, titanium, and nickel-based superalloys.

- Complexity and Dimensional Accuracy

Investment casting enables superior design flexibility and tolerances up to ±0.005 inches. It goes well with intricate geometries, thin walls, and internal cavities.

Die casting provides good accuracy (±0.1 mm), which is ideal for housings, brackets, and enclosures with moderate complexity and repeatable dimensions.

- Lead Time and Scalability

Die casting features rapid turnaround and high scalability to produce components upon final casting. Investment casting has longer lead times due to the mold shell for the ceramic cavity and dewaxing.

Frequently Asked Questions (FAQs)

- Which casting method is better for thin-walled components?

Die casting is better for thin-walled parts, as the high-pressure injection suffices for walls as thin as 0.5 mm. Investment casting can achieve thin sections, which are more limited by mold strength.

- Can investment casting be automated like die casting?

Die casting is highly automated, but investment casting involves manual steps like wax pattern assembly and shell building. Still, automation is increasing in wax injection and robotic dipping stages.

- Which casting method offers better repeatability for mass production?

Investment casting, with expendable ceramic molds, marks further variability between batches. Die casting offers superior repeatability due to permanent steel molds and automated cycles.

- Is die casting suitable for aerospace-grade components?

Die casting in the aerospace industry covers non-critical + lightweight parts like brackets and housings. For high-stress or high-temperature components, investment casting is preferred for flexibility.

- How do casting methods affect porosity and structural integrity?

Die casting is more prone to gas porosity, notably affecting the mechanical strength. Investment casting, with slower cooling and gravity feed, mainly results in denser but uniform microstructures.

Conclusion

A rightful selection from investment casting and die casting shapes the efficiency, quality, and scalability of your products. Each casting method comes with specified benefits against potential limitations. Then, there are industry-specific applications, which should give you some insight into what to choose.

Get the Best Possible Die Casting Services at HONJENNY

Honjenny has been a leader in the metal casting portfolio for decades. We guarantee your satisfaction through innovation, commitment, and precision. Contact us to know more about our casting services.