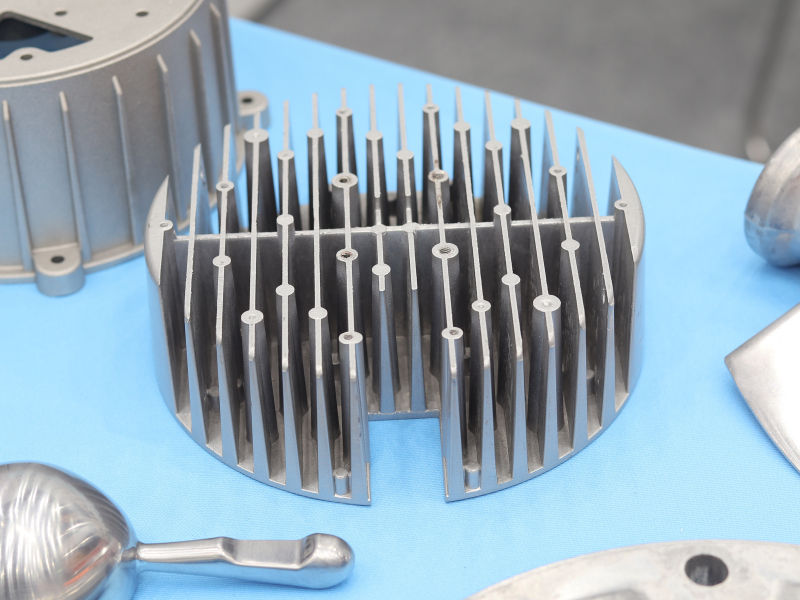

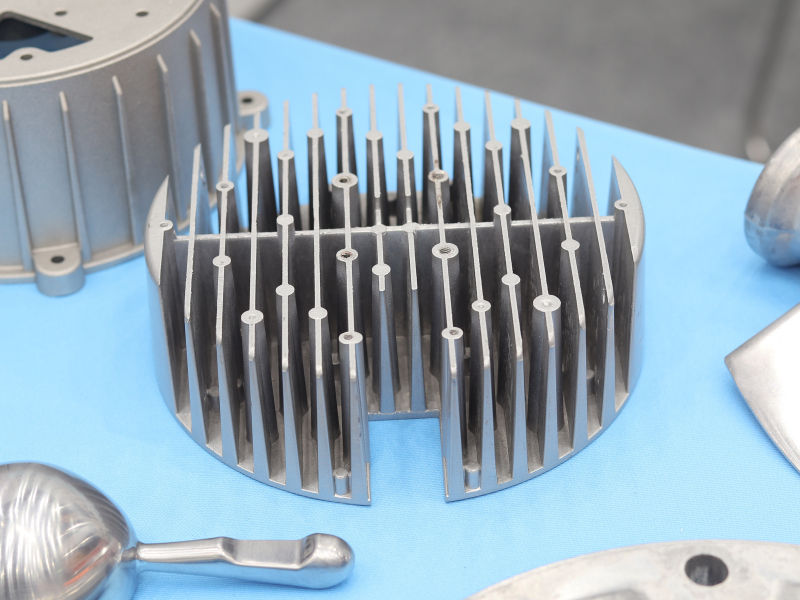

Thermal Management

High-performance chips generate heat. Our Aluminum die castings (ADC12/AlSi10Mg) serve as integrated heat sinks, dissipating heat 10x faster than plastic to protect sensitive processors.

In the fast-paced electronics market, speed and precision are non-negotiable. Honjenny combines high-pressure die casting with 5-axis CNC machining to produce complex housings that act as both structural chassis and thermal heat sinks.

High-performance chips generate heat. Our Aluminum die castings (ADC12/AlSi10Mg) serve as integrated heat sinks, dissipating heat 10x faster than plastic to protect sensitive processors.

In a wireless world, signal integrity is key. Our metal housings provide natural EMI shielding, protecting internal circuits from interference without the need for conductive paints.

In a wireless world, signal integrity is key. Our metal housings provide natural EMI shielding, protecting internal circuits from interference without the need for conductive paints.

See how we help brands launch successful products.

Consumer electronics product cycles are short and demand surges can be sudden. Honjenny operates 24/7 with automated robotic die casting cells and CNC lines. We offer:

Rapid Prototyping: Soft tooling options to get T1 samples in as little as 2 weeks.

High Capacity: Capable of delivering 500k+ units per month.

Strict QC: Automated vision systems to detect cosmetic defects on every single part.

We know appearance is everything in electronics. Honjenny implements strict visual inspections under controlled lighting to ensure parts are free from scratches, dents, or flow marks. We also use professional tools to guarantee the color matches your sample perfectly every time.

We support your R&D speed! For design verification, we can deliver CNC or 3D printed prototypes in as little as 24 hours. This allows you to test fit and function immediately before investing in mass production molds.

To help you save space and weight, we can achieve wall thicknesses as low as 0.4mm for Zinc and 0.5mm for Aluminum. We use high-speed injection technology to ensure the parts are fully filled and strong, even at these thin gauges.

Yes. Aluminum cases act as natural heat sinks. By switching from plastic to Honjenny’s aluminum die casting, you can dissipate heat significantly faster, protecting your processors and batteries from overheating during high-performance tasks.

We don’t rely on casting alone. We use secondary CNC machining to cut the port openings and screw holes. This ensures tolerances within ±0.02mm, so your connectors and PCBs fit perfectly without any gaps or misalignment.

It depends on your goal. If you want a heavy, premium feel (like a luxury watch) with a shiny finish, choose Zinc. If you need a lightweight part that handles heat well (like a laptop or drone), Aluminum is the better choice.