Producing complex yet durable parts with optimal accuracy is never easy. However, zinc die casting, a highly precise process, is perfect for such scenarios. Zinc alloys are found in countless everyday products.

Die casting, when executed perfectly, harnesses the best of zinc alloys. Expect small yet detailed parts at scale. That’s where zinc alloy die casting becomes crucial for engineers, designers, and manufacturers.

What Is Zinc Alloy Die Casting?

It refers to a high-precision manufacturing process. Molten zinc alloys are injected into steel molds (dies) under high pressure (1500 to 25000 psi). The die casting technology enables rapid production of stable, complex, and durable components with excellent surface finishes.

Zinc Die Cast Material: Physical and Mechanical Properties

- High Density: 6.6 – 6.8 g/cm³, which is ideal for compactness.

- Toughness: Excellent impact resistance comes with fatigue strength.

- Dimensional Stability: Maintains incredibly tight tolerances over time.

- Recyclability: Zinc alloys are 100% recyclable with minimal degradation.

- Surface Finish: Superior plating and painting compatibility.

Common Zinc Alloys Used in Die Casting

a. Zamak Series (Zinc + Aluminum + Magnesium + Copper)

- Zamak 2: Highest strength and hardness; used for wear-resistant parts.

- Zamak 3: Most commonly used; excellent castability and dimensional stability.

- Zamak 5: Slightly stronger than Zamak 3; better corrosion resistance.

- Zamak 7: Improved fluidity and ductility; ideal for thin-walled parts.

b. ZA Series (Zinc – Aluminum Hybrids)

- ZA-8: Higher aluminum content; stronger than Zamak 3; good for structural parts.

- ZA-12: Balanced strength and castability; used in medium-duty applications.

- ZA-27: Highest strength and hardness; suitable for high-load components.

Comparison Table: Zinc Die Casting Alloys

| Zn Alloy | Tensile Strength (MPa) | Hardness (Brinell) | Casting Temp (°C) | Exclusive Feature(s) |

| Zamak 2 | 350 | 100 | 400 – 420 | High strength, wear resistance |

| Zamak 3 | 280 | 82 | 390 – 410 | Best castability, stable dimensions |

| Zamak 5 | 320 | 85 | 395 – 415 | Stronger, excellent corrosion resistance |

| Zamak 7 | 275 | 80 | 385 – 405 | High fluidity, ductile |

| ZA – 8 | 380 | 100 | 470 – 490 | High strength, good for machining |

| ZA – 12 | 410 | 105 | 480 – 500 | Balanced properties |

| ZA – 27 | 450 | 120 | 490 – 510 | Highest strength, structural use |

Zinc Die Casting Process: Step-by-Step Overview

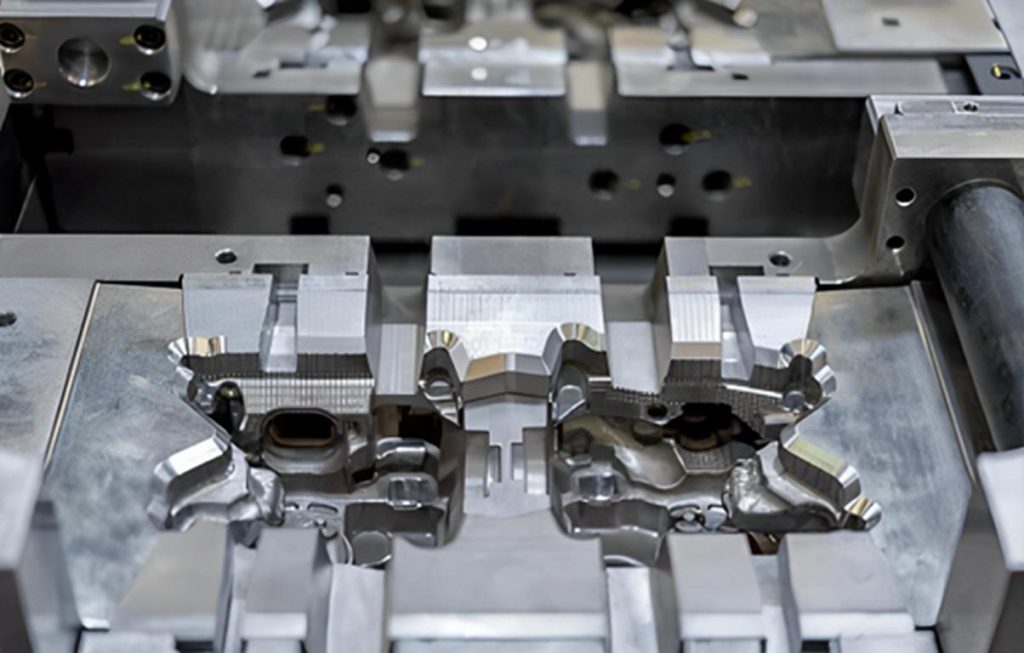

a. Tooling (Mold Design)

Precision tooling lays the foundation for zinc die-cast components. Molds (dies) are made from hardened steel using CNC machining and EDM. The dies can withstand thousands of injection cycles with tight tolerances (±0.05 mm or better).

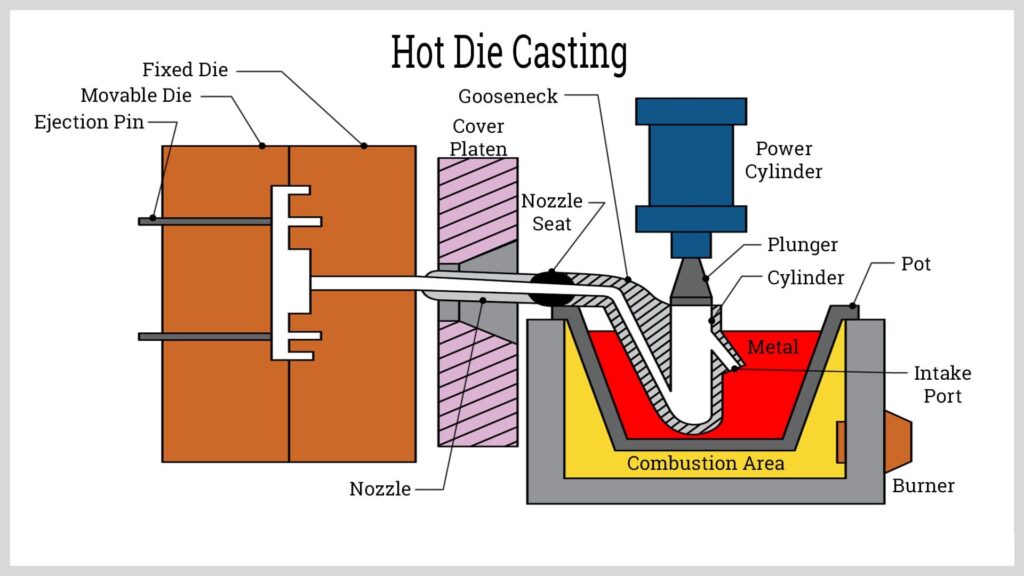

b. Melting + Injection

Zinc alloys are melted in a furnace at 420°C – 450°C. The molten zinc is injected directly into the mold using a gooseneck and hydraulic piston system. Injection pressures range from 1,500 to 25,000 psi. Such pressure ensures rapid mold filling for minimal porosity.

c. Solidification for Ejection

Zinc solidifies quickly due to its high thermal conductivity. The mold is cooled using internal channels, allowing cycle times as short as 15 – 60 seconds. Once solidified, the part is ejected using mechanical pins or slides.

d. Trimming for Surface Treatment

Excess material (flash) is trimmed using automated presses or manual tools. Surface finishing options include –

- Polishing for aesthetic finishes.

- Electroplating (nickel, chrome) for corrosion resistance.

- Powder coating or painting for color and texture.

e. Quality Inspection

Manufacturers conduct dimensional checks using CMM. X-ray inspection for internal porosity or voids also takes place. You may ask for visual and tactile checks for surface finish and defects.

Hot Chamber vs Cold Chamber (Like Aluminum Die Casting)

There are other casting processes for other metals than hot chamber casting. Sand casting for za alloys or zinc-based alloys may be subjected to ultimate tensile strength.

Hot Chamber Die Casting: It’s the most common for zinc alloys due to a relatively low melting point. The metal is held in a pool inside the machine and injected via a gooseneck.

The hot chamber process features fast cycle times with longer mold life due to lower thermal stress. You can achieve tighter tolerances and smoother finishes.

High production efficiency prevails for small to medium parts with low energy consumption. Zamak 3 is widely used in hot chamber casting.

Cold Chamber Die Casting: It’s used for larger die casting materials or special zinc – aluminum alloys (ZA-27). Molten metal is ladled into the injection chamber manually or robotically.

Slower cycle times (low die casting production rates) still create high-strength structural components. ZA-8 and ZA-27 alloys are cast using cold chamber or lost wax casting methods.

Advantages of Zinc Alloy Die Casting

High Strength and Hardness

Zinc alloys like Zamak 2 and ZA-27 offer tensile strengths up to 450 MPa. No wonder zinc’s excellent bearing capability makes it to automotive brackets, gear housings, and structural connectors.

Excellent Thin-Wall Capability

Zinc’s superior fluidity allows it to fill intricate mold cavities with walls as thin as 0.3 mm. It outperforms Al and Mg in casting fine details. It’s ideal for miniature components in electronics, locks, and medics.

Dimensional Stability

Zinc die-cast parts maintain tight tolerances (±0.05 mm) even after thousands of cycles. Low shrinkage during solidification ensures consistent part geometry, critical for assemblies requiring precise fitting.

Superior Fluidity + Electrical Conductivity

Zinc’s superior casting fluidity flows easily into complex molds, reducing secondary machining. It enables net-shape or near-net-shape production. Zinc also solidifies rapidly due to its high thermal conductivity.

Easy Secondary Machining

Zinc alloys are easy to drill, tap, and mill, making them ideal for post-casting modifications. They also accept various finishes like electroplating (chrome, nickel), powder coating, painting, and polishing.

Low Production Cost per Part

High-speed casting, minimal machining, and long die life result in low cost per unit. It’s particularly true for runs over 10,000 parts. Zinc’s ability to produce multi-cavity molds further boosts the output.

100% Recyclable Material

Zinc is infinitely recyclable without loss of mechanical properties. Scrap from trimming and rejected parts is easily remelted and reused, supporting closed-loop manufacturing.

Zinc Die Casting Applications

Automotive Industry

- Door handles, locks, and hinges.

- Bezels, knobs, and decorative elements.

- Under-the-hood components.

Zinc die casting is used in over 70% of decorative and functional automotive hardware across North America and Europe. Zamak 3 and Zamak 5 are the most common alloys.

Electronics/Electrical Components

- Smartphone frames and connectors.

- Laptop hinges and brackets.

- EMI/RFI shielding enclosures.

- Switch housings and terminal blocks.

Many smartphone charging ports and connector housings are made using Zamak 7. Its fluidity and ductility suit ultra-thin walls within tight tolerances.

Medical + Dental Equipment

Zinc die casting supports the production of small, precise, and hygienic components –

- Instrument housings.

- Brackets and clamps.

- Dental tool handles.

- Diagnostic device enclosures.

Zinc die-cast parts are used in ISO-certified medical devices in Germany and Japan. Dimensional accuracy and surface finish are critical for optimal sterilization regarding performance.

Hardware/Tools

- Padlocks and key mechanisms.

- Tool handles and grips.

- Fasteners and brackets.

- Window and door hardware.

Zinc die-cast locks and latches are used in over 60% of residential/commercial buildings in urban Asia. It comes from zinc’s cost-efficiency and corrosion resistance.

Consumer Appliances

Zinc die casting crafts aesthetic, durable, and functional lighting fixtures and household appliances –

- Lamp bases and housings.

- Control knobs and switches.

- Microwave and oven handles.

- Decorative trims and bezels.

- Heat sinks and die-cast toys.

Appliance manufacturers in South Korea and Italy use zinc die-cast knobs and trims for high-end ovens and cooktops. They contain a finish with chrome or powder coating for premium aesthetics.

Industrial Equipment

Zinc die casting supports precision components in defense and heavy machinery applications –

- Sensor housings.

- Mounting brackets.

- Control panel enclosures.

- Protective casings.

Defense contractors in the US use zinc die-cast parts for ruggedized electronics and sensor mounts. Such parts incorporate dimensional stability and EMI shielding, which are essential.

Design Guidelines for Custom Zinc Die / Zinc Casting

Zinc die casting can only offer such unmatched precision, speed, and surface quality when appropriately implemented. Designers must follow specific guidelines to optimize the manufacturability, performance, and cost-efficiency.

Optimal Wall Thickness

- Standard range: 0.5mm – 3mm

- Minimum feasible: As low as 0.3 mm for Zamak 7

In high-volume Chinese electronics production, thin walls of 0.4 mm can reduce material by up to 15%.

Draft Angle Requirements

- Recommended: 1 – 3 degrees per side to aid ejection

- As-cast surfaces: Require more draft than polished or plated surfaces

Avoid zero-draft walls to prevent sticking and die wear.

Fillet and Radius Recommendations

- Internal fillets: ≥0.75 mm to reduce stress concentration.

- External radii: ≥1 mm for smoother flow and better surface finish.

Such values can reduce die erosion to improve mold longevity.

Rib and Boss Design

- Ribs: Use to reinforce thin sections without increasing wall thickness.

For height ≤ 3× thickness; thickness ≤ 0.6× wall thickness.

- Bosses: Add fillets at the base and ensure uniform wall thickness.

Such measurements are perfect for mounting or threaded inserts.

Hole and Slot Specifications

- Minimum hole diameter: ≥1 mm.

- Depth-to-diameter ratio: ≤4:1 for blind holes.

- Slots: Maintain consistent width and avoid sharp corners.

Automotive suppliers in Mexico use cast-in holes for trim parts, reducing secondary machining by 30%.

Standard Tolerance Capabilities

- Achievable: ±0.05 mm for zinc alloys.

- Critical dimensions: May require post-machining or grinding.

Smartphone frames cast in South Korea maintain ±0.03 mm tolerance for camera alignment zones.

Factors Affecting Dimensional Accuracy

- The temperature and cooling rate.

- Alloy shrinkage (Zamak 3 = 1.2%).

- Mold wear and flash formation.

- Injection pressure and fill time.

Secondary Operations for Precision

- Secondary CNC machining for critical fits.

- Reaming and tapping for threaded holes.

- Grinding and polishing for mating surfaces.

Surface Finish Options

Zinc alloys produce smooth surfaces + wear properties with minimal porosity.

- Standard roughness: Ra 1.5 – 3.0 µm

- Polishing and Buffing: They’re used for cosmetic uses like appliance knobs and automotive trims. Buffing enhances reflectivity with superior creep resistance before plating.

- Electroplating: Common finishes include chrome, nickel, and brass. It enhances corrosion resistance and aesthetics. Over 80% of zinc bathroom fixtures are chrome-plated in Europe.

- Powder Coating: It provides a durable and eco-friendly finish. They’re available in matte, gloss, and textured options. It’s ideal for outdoor hardware and industrial enclosures.

- Painting and Anodizing Alternatives: Zinc cannot be anodized like aluminum, but epoxy and acrylic paints offer excellent adhesion. Priming is recommended for long-term durability.

Design Optimization Tips

- Minimizing Porosity Risks: Use uniform wall thickness to avoid trapped air. Avoid thick sections that cool unevenly. Optimize gate and vent locations for smooth flow.

- Parting Line Placement: Place at largest cross-section or flat plane. Avoid placing on cosmetic surfaces. Flat parting lines reduce flash and simplify trimming.

- Gate Location Strategies: Position gates to promote uniform fill and reduce turbulence. Use overflow wells to capture impurities. Avoid gating into thin sections or near holes.

Quality Control with Industry Standards in Zinc Die Casting

ISO 9001:2015

It ensures that zinc die casting manufacturers maintain a consistent, documented, and tight process control. It also covers everything from design and development to production and customer satisfaction.

IATF 16949

It’s developed by the International Automotive Task Force, built on ISO 9001 with automotive-specific requirements. It emphasizes defect prevention, traceability, and a zero-defect culture.

NADCA Guidelines

NADCA provides comprehensive technical standards for zinc die casting. It covers die design, process control parameters, safety practices, material specifications, and tolerances.

How to Choose a Reliable Zinc Die Casting Partner?

Partnering with the right manufacturer can help economically manufacture cast parts. Zamak alloys, hot chamber zinc, or material properties – you can expect the best.

Experience in Zinc Pressure Die Casting

Look for manufacturers with 5+ years of proven experience in zinc die casting with alloys like Zamak 3, Zamak 5, and ZA-8. Expertise in hot chamber casting is essential for high-volume, thin-walled parts.

Advanced CNC Machining with Surface Treatment Capabilities

Post-casting operations like drilling, tapping, reaming, and polishing are critical for precision parts. Surface finishing options should include electroplating (chrome, nickel, brass), powder coating, painting, and buffing.

Quality Assurance System (Certifications)

Ensure the partner is certified to ISO 9001 and IATF 16949 (for automotive-grade production). Ask about X-ray inspection, CMM measurement, and SPC (Statistical Process Control).

Assist with Design for Manufacturability (DFM)

A reliable partner should offer DFM support during early design stages. It includes optimizing wall thickness, recommending draft angles (1–3°), suggesting gate, and parting line placement.

Frequently Asked Questions (FAQs)

1) Can zinc die casting be used for heat-sensitive applications?

With limitations. Zinc’s low melting temperature (420°C) comes with moderate thermal conductivity. It’s suitable for moderate-heat environments.

2) What are the corrosion resistance properties of zinc die-cast parts?

Zinc naturally forms a protective oxide layer and can be further enhanced with coatings. Zamak 5 and ZA-8 offer better corrosion resistance in humid or coastal environments.

3) How durable are zinc die-cast parts under mechanical stress?

Zinc alloys like ZA-27 offer high tensile strength (up to 450 MPa) and impact resistance. It’s suitable for structural brackets, gears, and load-bearing components.

4) What is the standard lifespan of a zinc die casting mold?

Zinc die casting molds can last up to 1 million cycles. It’s significantly longer than aluminum molds. Such robustness comes from lower thermal fatigue from a lower melting temperature.

5) Are there fire safety concerns with zinc die casting?

Zinc alloys are non-flammable and self-extinguishing. However, care must be taken during melting and casting to avoid zinc oxide fumes at high temperatures.

Conclusion

Zinc alloy die casting combines precision, durability, and flexibility. You can expect high-performance parts that meet the demands of modern applications. Zinc die casting enables unmatched efficiency, repeatability, and surface quality.

Perfect Zinc Die Casting Services at HONJENNY

Honjenny has been a top brand in the industry for about 30 years. We specialize in optimal zinc alloy die casting with innovation, commitment, and precision. Contact us to know more about the services.