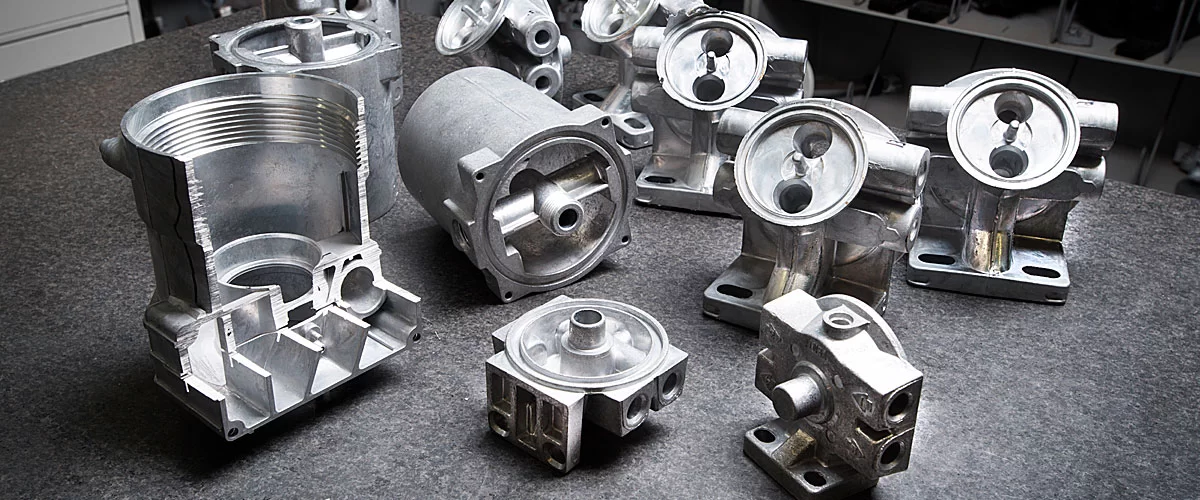

Aluminum die casting offers a precise and efficient way to produce complex, lightweight, and durable components. Its versatility and cost-effectiveness make it a preferred choice across industries—from automotive to electronics.

In this guide, you’ll explore how aluminum die casting enhances performance, reduces costs, and meets modern design standards for quality, innovation, and sustainability.

Understanding Aluminum Die Casting: The Basics

Die refers to the reusable steel mold used to shape molten metal under high pressure. Such dies are engineered to withstand repeated cycles and maintain tight tolerances. Casting is the process of shaping molten metal by pouring/injecting it into a mold for solidification.

Aluminum alloys primarily used in casting usually feature ADC12, A380, and AlSi10Mg. They’re in favor of excellent fluidity, superior strength, and high corrosion resistance. Such die-cast alloys are exclusively tailored to meet specific mechanical and thermal requirements.

Why is Aluminum Suitable for Casting?

Aluminum’s unique metallurgical properties make the element a global favorite for the process. The top properties from a die casting perspective include –

· Lightweight: The density of aluminum measures about 2.7 g/cm³, making it three times lighter than steel. Such lightness reduces fuel consumption and improves portability.

· Corrosion Resistance: Highly reactive aluminum naturally forms a protective oxide layer. That’s why it’s ideal for outdoor applications and marine environments.

· Thermal and Electrical Conductivity: Aluminum can conduct heat and electricity efficiently. Such behavior suffices for LED housings, heat sinks, and/or electrical enclosures.

· Recyclability: Over 75% of all aluminum ever produced is still in use today. Manufacturers can recycle it without losing much of the default mechanical properties.

The global aluminum die casting market is set to reach $112B by 2030. The surging demand has been driven by lightweight metal components in EVs, 5G infrastructure, and renewable energy systems.

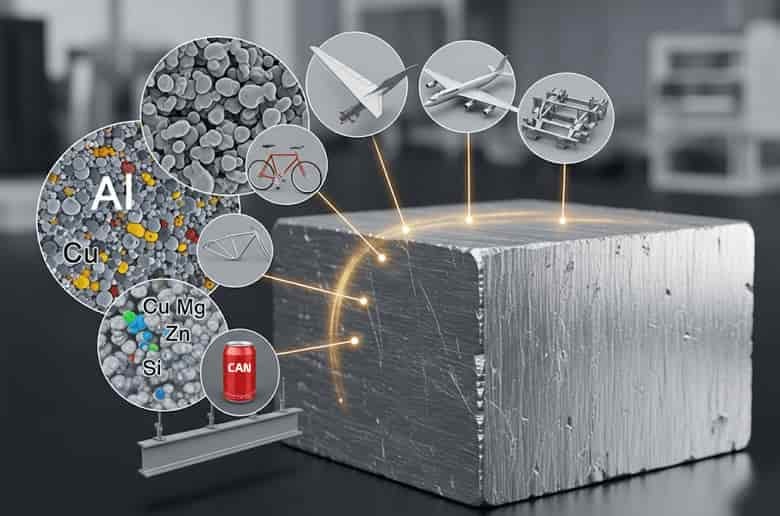

Common Aluminum Alloys Used in Die Casting

Die casting relies on engineered aluminum alloys instead of pure aluminum. Alloys (majority of aluminum with other non-ferrous materials) can fulfill the necessary requirements, like –

· A380 (Al-Si-Cu): The most dominant alloy features excellent fluidity, high dimensional stability, and corrosion resistance. It’s heavily applied across automotive transmission cases, engine blocks, and electronic housings throughout the US.

· ADC12 (Al-Si-Mg): It’s specifically popular across Japan and Southeast Asia. ADC12 provides better strength and high castability due to more Si and Mg content. Motor housings, appliance frames, and industrial components are made from it.

· Al-Si Alloys (like – AlSi10Mg): They’re well-known for high fluidity against low shrinkage. These alloys are heavily favored across intricate castings of thin-walled sheets. For instance, Al-Si alloys are also standard in aerospace and consumer electronics.

· Al-Mg Alloys (A356, A390): This category comes with good corrosion resistance and weldability. You can expect a good balance of mechanical strength and ductility. Superb castability makes them suitable for marine applications and outdoor enclosures.

Why Alloy Composition Matters?

Pure aluminum is notably soft, highly reactive, and challenging to cast under pressure. Alloying elements like silicon (Si), copper (Cu), magnesium (Mg), and iron (Fe) dramatically improve –

· Strength + Hardness: Copper and Mg increase tensile strength and load-bearing capacity.

· Machinability: Zinc and manganese improve surface finish and ease of post-processing.

· Thermal Conductivity: Alloying elements can effectively retain high thermal conductivity.

· Corrosion Resistance: Mg + Si enhances resistance to oxidation and environmental degradation.

For instance, A380’s silicon content (7.5% – 9.5%) improves mold filling and reduces shrinkage. In contrast, ADC12’s magnesium (up to 1.3%) boosts strength and corrosion resistance.

Pure Aluminum vs Aluminum Alloy Die Casting

In case you need a more factual justification, take a look at the side-by-side comparison. It clearly outlines the differences between alloys and pure aluminum regarding die casting suitability.

| Property/Aspect | Pure Aluminum | Aluminum Alloys |

| Tensile Strength | ~90 Mpa | 300 – 350 MPa |

| Castability | Poor (low fluidity) | Excellent (high fluidity) |

| Corrosion Resistance | High | High (often enhanced) |

| Machinability | Poor | Good to excellent |

| Thermal Conductivity | Very high | High (slightly reduced) |

| Applications | Foils, wires, packaging | Automotive, electronics, aerospace |

Aluminum Die Casting Process: A Step-by-Step Overview

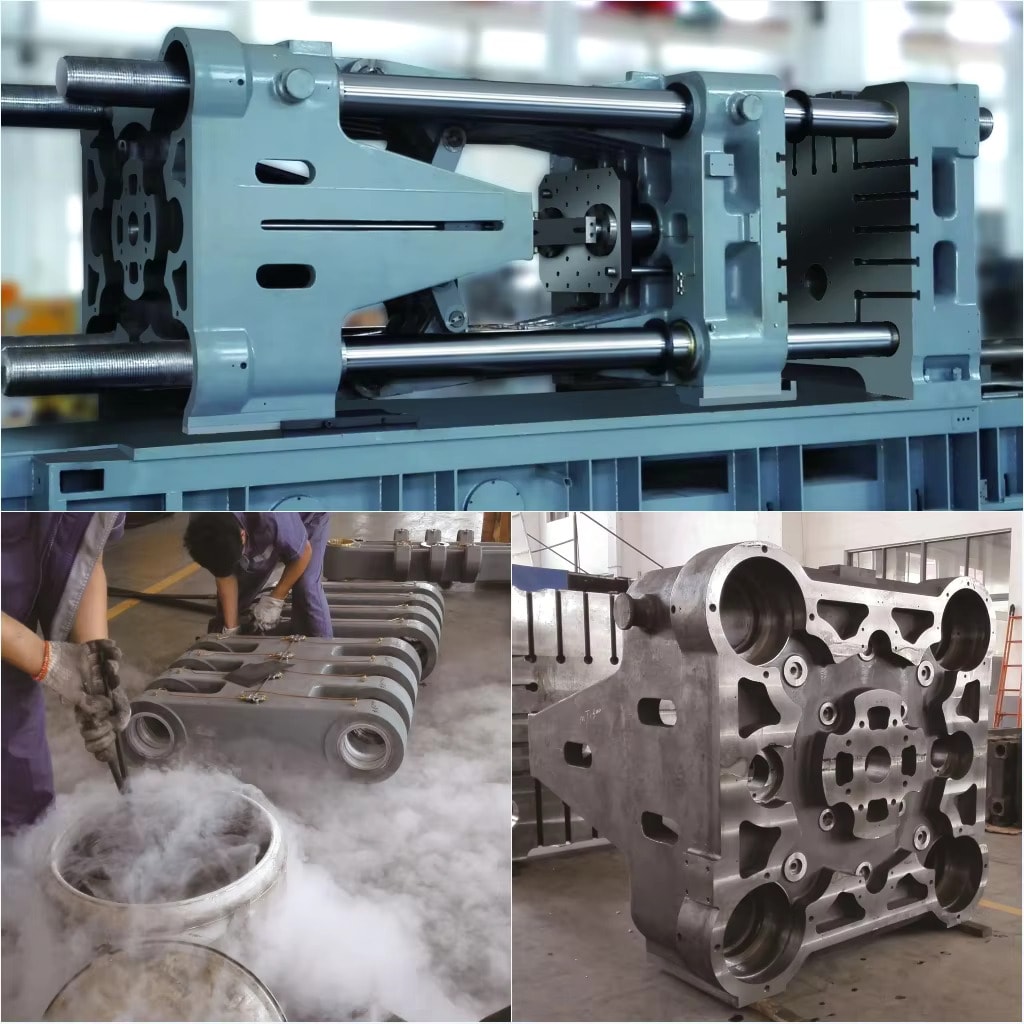

It’s a multi-stage process ranging from mold creation to surface finishing. Thorough execution via die casting machines enables high-volume production. Each step is engineered for speed, repeatability, and quality control.

Step #01: Mold Creation (Die Making)

It begins with precision tooling (permanent mold casting). Hardened steel dies are crafted to form the mold cavity. They’re perfectly designed with CAD software.

The molds are manufactured by CNC machining, EDM (Electrical Discharge Machining), and grinding within tight tolerances (within ±0.1 mm).

The life expectancy of dies ranges from 50K to over 500K shots based on part complexity. Some invest in multi-cavity dies to handle mass-scale production.

Step #02: Melting Aluminum Alloy

Aluminum alloys (A380, ADC12, AlSi10Mg) are melted in gas or electric furnaces at 660°C up to 700°C. Furnace design ensures consistent alloy fluidity, minimizes oxidation, and prevents gas entrapment.

Real-time control systems monitor temperature and alloy composition to maintain mechanical integrity.

Step #03: Injection into Mold

Molten metal fills the die cavity using high-pressure injection. The pressure usually ranges from 10 to 175 MPa. It ensures complete mold filling with aluminum in thin-walled or intricate shapes.

Cold chamber machines are used for aluminum due to its high melting point. Tesla’s Gigacasting uses pressures exceeding 100 MPa to cast large vehicle underbodies in a single shot.

Step #04: Cooling and Solidification

Once injected, the aluminum rapidly cools and solidifies inside the mold. Controlled cooling rates (50 to 150°C/sec) can achieve optimal microstructure and minimize porosity.

Cycle times range from 30 to 90 seconds, depending on part size and complexity. China’s die casting hubs optimize cooling to prevent very high temperatures.

Step #05: Ejection and Trimming

After solidification, ejector pins push the casting out of the mold. Proper draft angles (1°- 3°) are built into the die to prevent sticking or damage. Excess material called flash gets trimmed using mechanical or robotic systems.

Trimming removes gates, runners, and sharp edges, preparing the part for finishing. Many small-scale die casters in the developing countries rely on manual trimming to balance cost with quality.

Step #06: Surface Treatment + Finishing

Post-processing enhances appearance, corrosion resistance, and functionality. Common treatments include:

· Anodizing: Adds a protective oxide layer, often used in electronics and consumer goods.

· Powder Coating and Painting: Improves aesthetics and weather resistance.

· Polishing and Shot Blasting: Refines surface texture and removes residual burrs.

Automotive parts are powder-coated across Europe to meet environmental and aesthetic standards.

Different Die Casting Methods for Aluminum

Aluminum die casting primarily implements the cold chamber method and the high-pressure system. There are alternative casting processes to handle the metal’s high melting point and precision demand. Vacuum die casting is increasingly used for high-integrity parts.

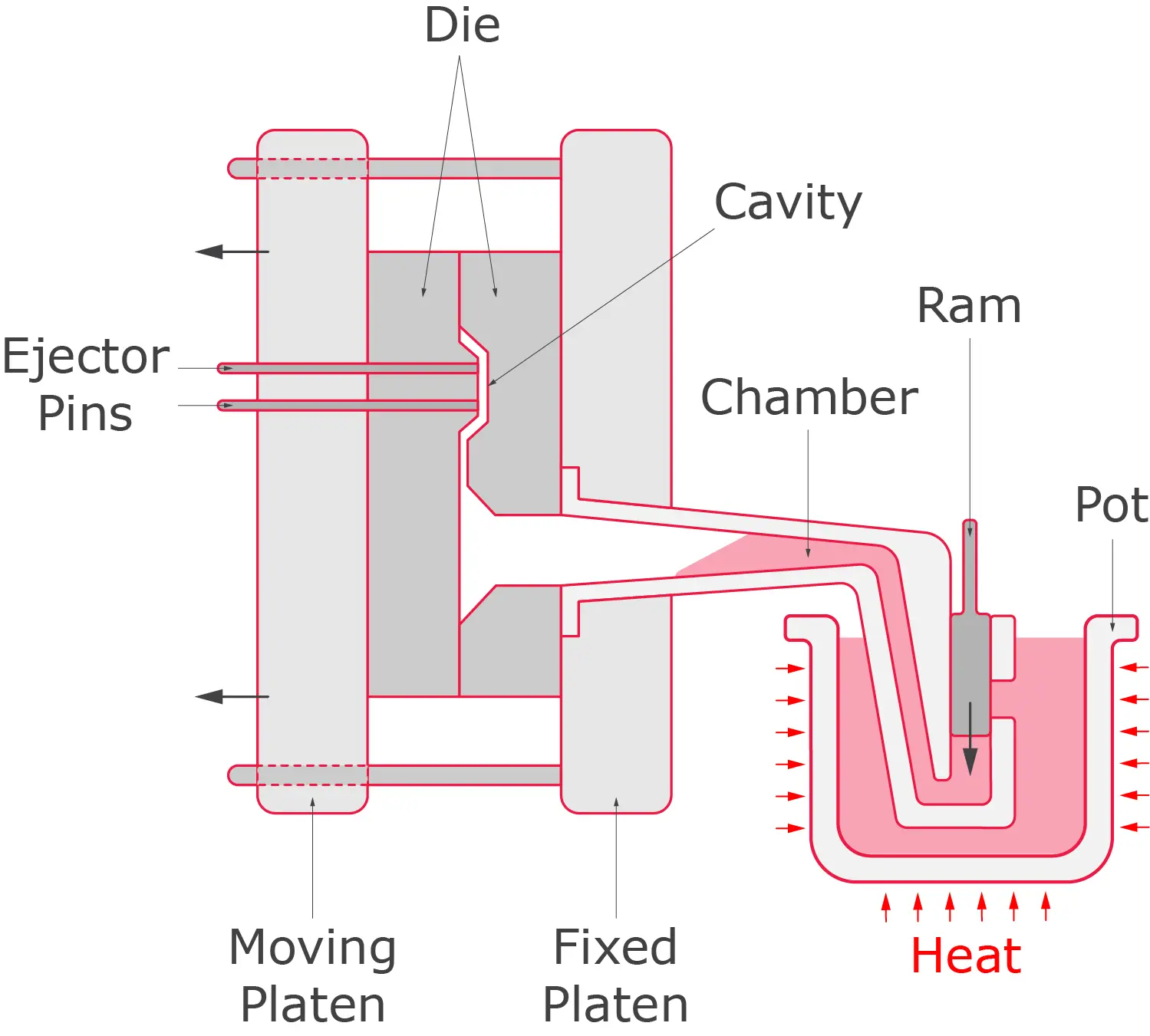

a. Hot Chamber vs Cold Chamber Die Casting

· Hot Chamber Die Casting: The injection system is submerged in molten metal. A gooseneck mechanism feeds metal directly into the die. However, it’s not suitable for Al as it has a high melting point (~660°C) and a corrosive nature that can damage submerged components.

· Cold Chamber Die Casting: Molten aluminum is ladled into a separate chamber before being injected into the die under high pressure. It can produce parts with excellent strength and surface finish. But manual ladling leads to somewhat slower cycle times.

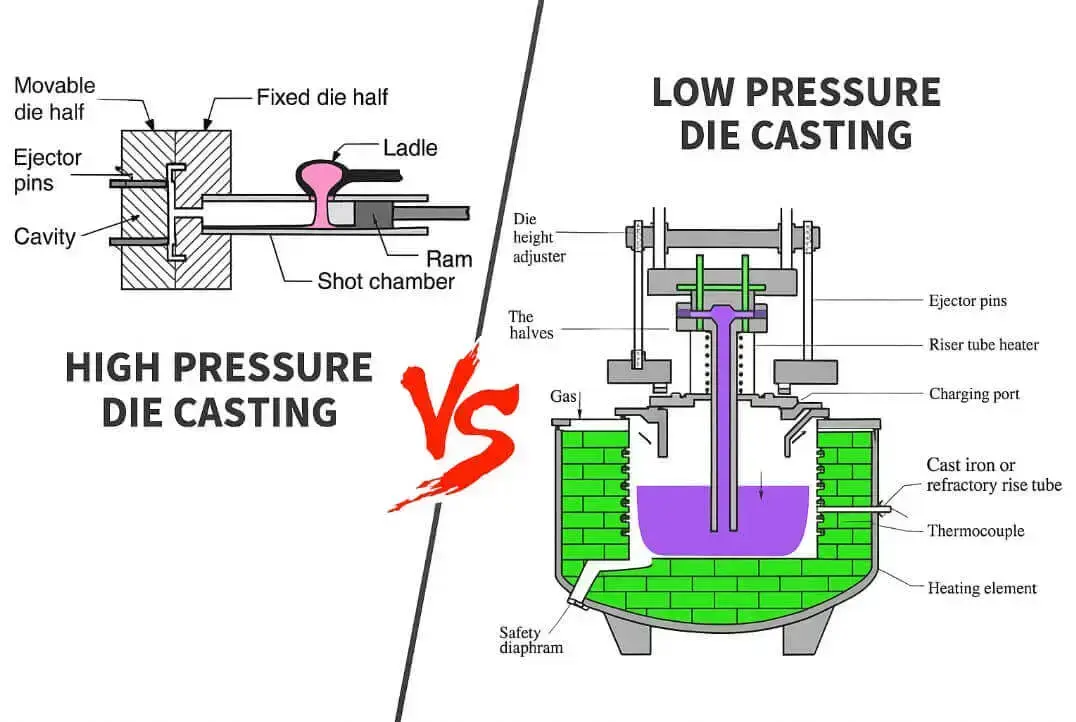

b. High-Pressure vs Low-Pressure Die Casting

· High-Pressure Die Casting (HPDC): Molten metal is injected at pressures up to 175 MPa. It enables fast cycle times and mass casting production. HPDC seems ideal for thin-walled and complex shapes.

But the method comes with high tooling and equipment costs to achieve such milestones. Nonetheless, HPDC dominates the aluminum die casting manufacturing portfolio due to speed and scalability.

· Low-Pressure Die Casting (LPDC): Molten metal is gently pushed into the mold using low pressure (~0.7 bar). Reduced turbulence and porosity initiate superior mechanical properties for thicker sections.

Slower cycle times make it less suitable for thin-walled or very complex shapes. LPDC is preferred for wheels, suspension arms, and engine components where strength and integrity are mandatory.

c. Vacuum Die Casting: Precision Without Porosity

Vacuum die casting enhances HPDC by removing air from the mold cavity before injection. A vacuum pump evacuates gases, minimizing porosity and improving metal flow.

Superior mechanical properties enable the casting of structural components with minimal defects. It’s ideal for heat-treated and weldable parts, but comes at a notably higher equipment cost.

Comparison Table: Aluminum Die Casting Methods

| Casting Method | Suitable For | Key Advantage |

| Hot Chamber | Low-melting alloys (Not for Al) | Fast cycles + integrated melting |

| Cold Chamber | High-melting aluminum alloys | Versatility + high-strength parts |

| High-Pressure | Thin + complex Al parts | Rapid production + surface finish |

| Low-Pressure | Thick + symmetrical parts | Low porosity + better integrity |

| Vacuum | Precision-critical components | Defect-free + weldable parts |

Benefits of Aluminum Die Casting Parts/Components

Aluminum die casting harnesses some exclusive advantages when appropriately implemented. The end-product more or less features a powerful combo of strength, flexibility, and efficiency.

a. Lightweight Yet Strong

Aluminum alloys used in die casting hold an impressively high strength-to-weight ratio. Manufacturers can replace heavier materials like carbon steel and iron without worrying about durability. Die-cast aluminum parts contribute to –

· Improved fuel efficiency in vehicles.

· Enhanced performance in aerospace and robotics.

· Better portability in consumer electronics.

b. Complex Geometric Design

Die casting allows net-shape manufacturing. In simple terms, manufacturers can produce parts with wall thicknesses as low as 1.5 mm. The same goes for intricate internal features without extensive machining. It’s the ideal case for –

· Smartphone frames, LED housings, and engine components.

· Multi-functional parts that combine strength, aesthetics, and precision.

c. Dimensional Accuracy

Aluminum die casting can comfortably achieve incredibly tight tolerances (±0.1 mm). That too maintains consistent part quality across thousands of cycles. Such repeatability is crucial for –

· Mass production in automotive and electronics.

· Reduced post-processing, saving time and cost.

d. Corrosion Resistance + Surface Finish

Aluminum naturally forms a protective oxide layer. It offers excellent corrosion resistance in humid, coastal, and industrial environments. Combined with surface treatments like –

· Anodizing for wear resistance and color.

· Powder coating for weatherproofing.

· Polishing or shot blasting for aesthetics.

Such finishes can extend the product’s life and enhance its appearance. Aluminum die-cast fan housings and motor covers benefit from powder coating to withstand tropical conditions.

e. Cost Efficiency

Despite the high initial tooling cost, aluminum die casting features low unit costs. Then, there’s the advantage of abundance regarding material availability. High-volume production can enjoy –

· Fast cycle times (30 – 90 seconds).

· Minimal machining and finishing.

· Higher utility with low scrap rates.

Industry-Specific Application of Die-Cast Aluminum

The manufacturing method is like a foundational technology across multi-billion-dollar sectors. Utilizing aluminum die casting spans across automotive, aerospace, electronics, energy, and consumer goods.

a. Automotive Industry

The automotive sector is the largest consumer of aluminum die-cast parts. Its demand is driven by reduced vehicle weight, improved fuel efficiency, and meeting emissions standards. Key applications –

· Engine blocks, cylinder heads, and transmission housings: Thermal conductivity dissipates heat, while strength supports high-stress uses.

· Suspension components, brackets, and mounts: Die casting ensures dimensional accuracy and vibration resistance.

· EV battery enclosures and motor housings: Lightweight but incredibly robust aluminum improves range and thermal management.

Tesla’s Gigacasting uses high-pressure aluminum castings to produce large underbody sections in a single shot. Thus, it replaces dozens of welded parts and reduces production complexity.

b. Aerospace Industry

Every gram of weight matters across aviation. Aluminum die casting offers high strength-to-weight ratios, corrosion resistance, and precision. Such properties are critical for flight safety and fuel economy. Applications –

· Avionics housings and brackets: Protect sensitive devices from high temperatures or vibration.

· Landing gear components and hydraulic systems: Require robust, fatigue-resistant materials.

· Structural supports and mounts: Must meet strict dimensional and mechanical standards.

Reducing aircraft weight by a mere 1 kg can save up to 100 liters of fuel annually. No wonder aluminum die casting equipment has been a strategic choice for sustainability.

c. Consumer Electronics

Aluminum die casting enables compact, stylish, and thermally efficient designs for electronics. Applications include –

· Smartphone frames and laptop bodies: Combine aesthetics with structural integrity.

· LED housings and heat sinks: Aluminum’s conductivity ensures safe operation and longevity.

· Power adapters and enclosures: Require electromagnetic shielding and heat dissipation.

Apple’s MacBook unibody frames are die-cast and CNC-finished for sleekness, durability, and heat management.

d. Energy/Power Sector

Aluminum die casting supports renewable energy systems, power distribution, and industrial controls. Common applications –

· Solar panel frames and inverter housings: Require corrosion resistance and thermal stability.

· Wind turbine components: Benefit from lightweight materials that reduce mechanical load.

· Electrical enclosures and connectors: Must withstand outdoor conditions and electrical stress.

Aluminum die-cast components have been in use for fan motors, switchgear housings, and energy-efficient appliances in South Asia. It supports the local manufacturing and electrification.

e. Appliances and Industrial Equipment

Aluminum die casting enables mass production of durable, low-cost components for household and industrial use. Noteworthy applications include –

· HVAC systems and compressors: Benefit from aluminum’s thermal properties and machinability.

· Washing machine frames, fan blades, and motor housings: Require vibration resistance and corrosion protection.

· Pumps, valves, and gearboxes: Aluminum die casting ensures max repeatability and tight tolerances.

Quality Control (Industry Standards)

Quality control in aluminum die casting is governed by rigorous international standards like ISO and NADCA. The standardization is supported by advanced testing methods such as X-ray inspection, CMM analysis, and tensile testing.

ISO and NADCA Standards

ISO (International Organization for Standardization) and NADCA (North American Die Casting Association) form the backbone of global quality assurance in aluminum die casting.

· ISO 9001: Consistent quality management, from initial design to final delivery.

· ISO 8062: Specifies dimensional tolerances for castings, critical for precision parts.

· ISO 14001: Encourages environmentally responsible manufacturing practices.

NADCA Product Specification Standards (2015 + 2024) provide detailed guidelines on alloy selection, tolerances, porosity control, pressure-tightness, and die design.

Common Testing Methods

Manufacturers employ a suite of non-destructive and destructive testing techniques to meet the standards.

· X-ray Inspection: Detects internal porosity, shrinkage cavities, and inclusions. Used in automotive transmission cases, aerospace brackets, and EV battery housings.

· Coordinate Measuring Machine (CMM) Inspection: Measures dimensional accuracy with micrometer-level precision. Ensures compliance with GD&T (Geometric Dimensioning and Tolerancing) standards.

· Tensile Testing: Evaluates mechanical properties like yield strength, elongation, and ultimate tensile strength. Often performed on test coupons cast alongside production parts.

Some other methods include pressure testing, hardness testing, dye penetrant inspection, and ultrasonic analysis. The final test list depends on the intended application and potential defect risks.

Choosing the Right Aluminum Die Casting Partner

Procurement managers and engineers must assess various design and execution factors. Whether you need aluminum die casting is equally essential. You should look for –

a. Expertise in Mold Design + Tooling

A reliable partner should demonstrate mastery of die design principles. Draft angles, uniform wall thickness, and venting systems should prevent defects like porosity and cold shuts.

Simulation tools can predict the mold flow and cooling analysis. Experience with multi-cavity dies for high-volume production and unit dies for modular flexibility is also essential.

b. Advanced CNC Machining for Dies

Precision tooling requires 5-axis CNC machining, EDM, and grinding for tolerances. It ensures accurate mold geometry, reduced cycle times and post-processing, and compatibility with complex part designs.

c. Surface Treatment for Cast Metal

A capable partner should offer anodizing, powder coating, and shot blasting for corrosion resistance and aesthetics. Polishing and coating technologies can meet cosmetic and functional requirements.

d. Certifications and Quality Management Systems

Look for partners with ISO 9001 for quality management, ISO 14001 for environmental compliance, and NADCA certification for die casting-specific standards. Ask the manufacturer –

· Do you conduct X-ray inspections, CMM analysis, and tensile testing?

· Can you achieve <100 PPM defect rates for critical parts?

· Do you support FAI (First Article Inspection) and SPC (Statistical Process Control)?

When Aluminum Die Casting Is the Right Choice

Choose aluminum die casting when –

· High-volume production is needed (>10,000 units/month).

· Parts require thin walls, complex geometries, and tight tolerances.

· Lightweight and corrosion-resistant materials are essential.

· An excellent surface finish is desired without extensive machining.

Not ideal for –

· Low-volume, large parts (consider sand casting).

· Ultra-high-strength components (consider forging).

· On-demand customization (consider CNC machining).

Frequently Asked Questions (FAQs)

1) What is the standard lifespan of a die in aluminum die casting?

A well-maintained steel die can last between 50,000 and 500,000 shots. It depends on alloy type, part complexity, and cooling strategy. High-volume automotive dies often exceed 300,000 cycles.

2) Can aluminum die casting achieve airtight or pressure-tight parts?

Yes. Proper gating, venting, and vacuum-assisted casting can meet pressure-tightness standards for hydraulic and pneumatic systems. X-ray and pressure testing are used to validate integrity.

3) What is porosity in die casting, and how is it controlled?

Porosity refers to gas pockets or shrinkage voids inside the casting. It’s controlled by optimized mold design, vacuum systems, and injection speed to withstand higher operating temperatures.

4) What is the role of die lubricants in aluminum die casting?

Die lubricants prevent sticking, reduce thermal fatigue, and improve surface finish. They are sprayed between cycles and often contain graphite or synthetic oils.

5) Can aluminum die-cast parts be welded?

Generally, die-cast aluminum isn’t ideal for welding due to porosity and oxide layers. However, vacuum die casting and post-machining can improve weldability for structural applications.

6) What wall thicknesses are achievable in aluminum die casting?

Standard wall thicknesses range from 1.5 mm to 4 mm. However, advanced techniques allow for as thin as 0.75 mm in small electronics or LED housings.

7) How does aluminum die casting support sustainability?

Aluminum is 100% recyclable without loss of properties. Die casting minimizes waste and energy use, making it a low-carbon footprint process for mass production.

8) Are aluminum die castings fire-resistant?

Aluminum has a melting point of ~660°C and does not burn, but it can deform under extreme heat. Surface treatments and alloy selection enhance fire resistance for electronics and enclosures.

9) What is the difference between primary and secondary aluminum in die casting?

Primary aluminum is virgin metal from bauxite, offering high purity. Secondary aluminum is recycled, cost-effective, and widely used in die casting with minimal performance loss.

Conclusion

Aluminum die casting enables precision, efficiency, and durability to deliver high-performance components. The process marks a scalable and cost-effective production with optimal quality. Al die casting is set to play a greater role in electric vehicles and renewable energy.

Get the Most Satisfactory Aluminum Die Casting Services with HONJENNY

Honjenny has been a leading name in the die casting industry for about 30 years. We specifically specialize in demanding aluminum die casting needs with innovation, commitment, and precision. Contact us to know what our experts can do to meet your project specs.